What Are the Core Differences Between ADSS and OPGW Fiber Optic Cables, and How Do You Select the Right One?

Do you feel confused about whether to use an all-dielectric self-supporting (ADSS) cable1 or an optical ground wire (OPGW) cable2 for your overhead fiber project? Are you worried that a wrong choice could create safety issues, introduce electromagnetic interference, or inflate project costs? I understand these concerns. Let me show you a systematic way to compare ADSS and OPGW cables, so you can decide which one is right for your network.

ADSS cables have non-metallic designs and excel where electromagnetic interference is prevalent. OPGW cables, meanwhile, serve dual roles for grounding and data transmission in high-voltage networks. Each cable type has a unique feature set that caters to specific overhead scenarios, so choosing the right cable involves analyzing voltage levels, mechanical requirements, and long-term maintenance needs.

I remember assisting on a major overhead line project where we had to retrofit existing towers. The utility wanted to upgrade their communication lines while maintaining robust protection from lightning. At first, we considered ADSS cables, but the towers’ existing ground wire arrangement made OPGW a more suitable replacement. The solution integrated fiber optic cores with the overhead ground wire. That project taught me how important it is to deeply understand the distinctions between ADSS and OPGW to keep systems safe, cost-effective, and reliable.

Why Are Fiber Optic Cables Used Along Power Lines at All?

Power lines span large areas, cross difficult terrain, and connect strategic nodes between cities and rural zones. Adding fiber optic communication along these routes offers a dual benefit: you can install data or telecommunication lines without building new infrastructure corridors, and you can reliably monitor or control the power network itself using SCADA3 or similar control platforms.

Placing fiber optics overhead leverages existing utility poles or high-voltage towers. This reduces construction costs, avoids complicated underground excavation, and simplifies maintenance checks, since line crews already patrol these routes. For utility companies, overhead fiber often integrates with supervisory control and data acquisition (SCADA) systems, remote grid management, and corporate communication channels.

Power lines intersect with telecom demands in modern infrastructures. Adding fiber optics along these corridors supports real-time monitoring, smart grid development, and high-speed data for remote communities. Overhead fiber cables in particular can handle difficult terrain such as mountains, rivers, or forests where burying cables is impractical or very expensive.

How Does ADSS Fiber Optic Cable Differ Structurally from OPGW?

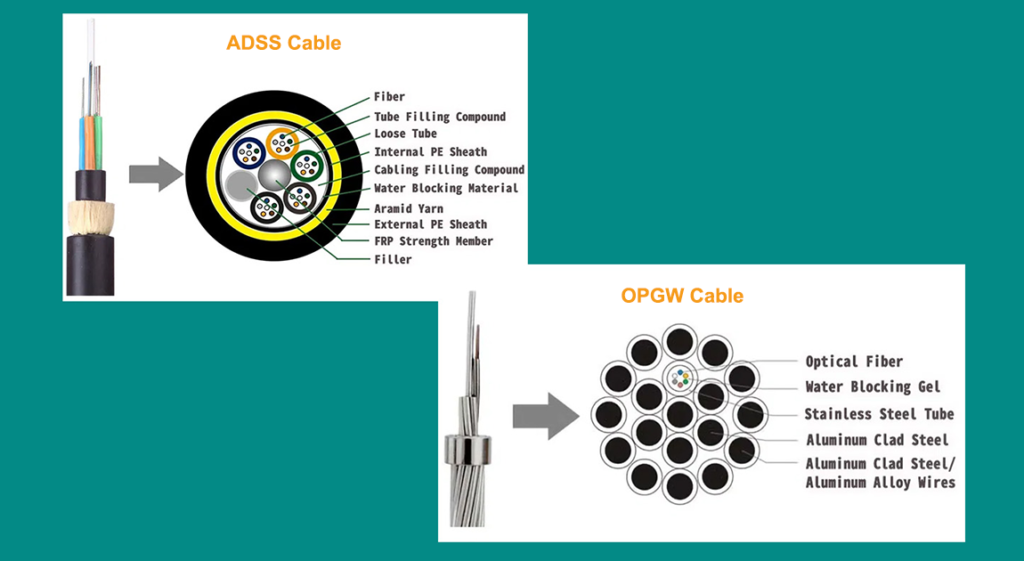

Since ADSS stands for All-Dielectric Self-Supporting, these cables have no metallic components. They rely on dielectric (non-conducting) strength members—like aramid yarn—and polymer jackets. OPGW, by contrast, features a metallic or steel-reinforced structure that houses optical fibers while also acting as a ground wire.

- ADSS Cable: Lightweight, dielectric materials, possibly including a track-resistant jacket4 if installed near high-voltage lines.

- OPGW Cable: Metallic strands (steel or aluminum-clad steel) around a central fiber tube, serving both as a ground wire and fiber carrier.

What Are the Specialized Functional Roles of ADSS and OPGW Cables?

ADSS cables excel in locations with strong electromagnetic interference or lower voltage lines where an added ground wire is not necessary. OPGW is usually deployed in high-voltage environments (110 kV and above) where replacing or upgrading the overhead ground wire with a fiber-enabled alternative provides lightning protection and data transmission in one.

Are ADSS Cables Easier to Install Than OPGW Cables?

In many cases, yes. ADSS cables are all-dielectric and can often be installed under live-line conditions. There is no need to integrate them into existing grounding schemes, so hardware and labor costs can be lower. OPGW installations, however, may require temporary line outages or specialized live-line work because the existing ground wire must be replaced or integrated with the new cable.

What Are the EMI and Electrical Interference Considerations?

ADSS cables avoid conduction paths; their dielectric design negates most electromagnetic or induction issues. OPGW cables, being metallic, require proper grounding and handling of any induced currents. In high-voltage lines, though, the metallic OPGW can help divert lightning strikes away from conductors.

How Do Environmental Factors Affect ADSS vs. OPGW Performance?

Both cables handle wind, ice, UV exposure, and temperature shifts. ADSS is lighter and may see fewer mechanical stresses, but track-resistant jackets can be necessary in high-voltage corridors. OPGW’s steel or aluminum alloy elements cope well with heavy mechanical loads and frequent lightning strikes but can face corrosion concerns in coastal or polluted environments.

Which Cable Has Higher Strength Requirements, and Why?

Each cable is engineered to specific tensile ratings. OPGW cables often use steel strands for robust mechanical performance on long spans. ADSS cables rely on aramid or glass yarn for tension support; advanced versions can handle heavy loads and large spans but remain lighter than OPGW on average.

How Do Maintenance and Long-Term Reliability Compare?

Properly installed ADSS and OPGW both offer decades of service. ADSS cables should be checked for surface tracking if near high voltages, while OPGW’s metallic strands must be inspected for corrosion or damage after repeated lightning strikes. Regular OTDR tests confirm fiber integrity, and hardware checks ensure no slack or excessive tension.

Why Is Cost Analysis Critical in Choosing ADSS or OPGW?

Costs involve cable price, installation (including possible line outages), hardware, and long-term maintenance. ADSS can be cheaper upfront and easier to deploy if you do not need a new ground wire. OPGW is more complex but can be cost-effective if you already plan to replace an existing ground wire on a high-voltage line.

How Do You Evaluate Project Needs to Select the Right Cable?

- Voltage Level: High-voltage lines often standardize on OPGW; lower or medium voltages may benefit from ADSS.

- Existing Ground Wire Condition: Replace it with OPGW if it’s outdated, or add ADSS if the ground wire is fine.

- Installation Constraints: If outages are hard to schedule, ADSS live-line installation5 may be preferable.

- Mechanical Loads: Both can be specified for demanding spans, but OPGW’s metal strands excel under extreme tension.

- Budget: Weigh the per-meter cable cost and labor expenses alongside future maintenance demands.

- EMI and Safety: ADSS eliminates conduction issues; OPGW helps ground the line effectively.

What Are the Main Advantages of Using ADSS Over OPGW?

- Dielectric Composition: No risk of induction or short-circuit currents in the cable.

- Simpler Installation: Can often be installed under “live” conditions without major line outages.

- Cost Efficiency: Generally cheaper if you don’t need to replace or integrate a ground wire.

- Versatility: Works well across different voltage levels, with track-resistant jackets for very high-voltage lines.

- Lightweight: Easier to handle, requiring simpler hardware.

Conclusion

Choosing between ADSS cables and OPGW cables depends on your voltage level, need for grounding, and tolerance for installation complexity. ADSS offers quick deployment and strong EMI immunity, making it ideal for adding fiber to existing lines without major grounding changes. OPGW integrates lightning protection and communication in a single cable, fitting high-voltage transmission lines that require robust mechanical strength. By evaluating power system requirements, mechanical loads, cost structures, and installation constraints, you can confidently select the cable type that aligns with your overhead fiber project goals.

-

This resource defines ADSS cable construction, detailing its all-dielectric composition and why it’s well-suited for overhead power lines. By clicking helps you understand how ADSS cables avoid electrical interference near high-voltage lines. ↩

-

This resource explains how OPGW combines grounding and optical fibers in one cable. Clicking helps you see why utilities integrate fiber communication with lightning protection in high-voltage environments. ↩

-

This resource outlines how SCADA systems leverage overhead fiber to monitor and control power grids. Clicking shows how real-time data enhances grid stability and reduces downtime. ↩

-

This resource describes how track-resistant jackets protect ADSS in high-voltage conditions. Clicking clarifies the importance of specialized outer sheaths that prevent surface arcing or jacket damage. ↩

-

This resource highlights best practices for installing overhead cables near energized lines. Clicking helps you understand the safety steps and hardware essentials for live or minimal-outage deployments. ↩