What Makes OPGW Fiber Optic Cable Specifications Stand Out?

In today’s rapidly advancing telecommunications landscape, finding the right fiber optic cable for power transmissions is crucial. Yet, many engineers and managers grapple with the challenge of selecting cables that balance both power and communication needs. The solution? Optical Power Ground Wire (OPGW)[^1] cables offer the perfect blend of ground wire capability and communication efficiency.

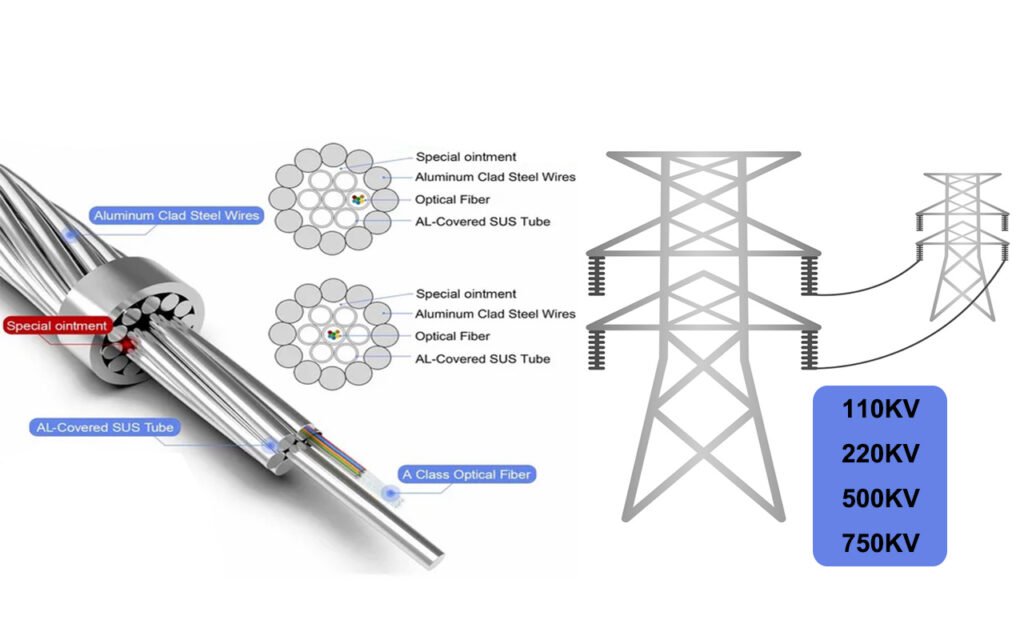

OPGW fiber optic cables are dual-purpose cables that combine the functions of ground wires and communication lines, essential for modern power transmission systems. They include various fiber types[^2], diverse construction elements, and robust physical and electrical properties, making them ideal for complex infrastructure projects.

Imagine a world where power disruptions are minimized, and communication lines remain stable even in adverse conditions. This is the promise of OPGW cables, which are engineered to withstand environmental challenges while maintaining high communication integrity. Let’s delve deeper into the specifications that make OPGW cables a preferred choice in the telecommunications industry.

How Do Fiber Types and Counts Impact OPGW Cables?

Understanding the diversity in fiber types and counts within OPGW cables is essential for tailoring them to specific applications. These specifications dictate how well the cables perform in varied environments and their capacity for data transmission.

OPGW cables can include optical fibers like G652D[^3], G655C[^4], and OM3[^5], with counts from 12 to 96 cores. This variety allows customization based on environmental conditions and communication needs, ensuring optimal performance in power transmission lines.

Dive deeper paragraph for H2: Each fiber type in OPGW cables serves different purposes. For instance, G652D fibers are standard single-mode fibers[^6] known for their low attenuation, making them suitable for long-haul communications. Conversely, OM3 fibers are multimode, designed for high-speed data over short distances, ideal for dense urban settings. The choice of fiber and core count directly influences the cable’s bandwidth and distance capabilities, allowing engineers to design systems that meet specific operational demands.

Fiber Type Specifications

| Fiber Type | Description | Best Use Case |

|---|---|---|

| G652D | Single-mode fiber with low attenuation | Long-distance communication systems |

| G655C | Optimized for long-distance communication | Suitable for environments with high chromatic dispersion |

| OM3 | Multimode fiber supporting higher bandwidth | Short-distance, high-speed data transmission |

What are the Construction Features of OPGW Cables?

The construction of OPGW cables combines advanced materials and innovative engineering to ensure durability, flexibility, and reliability. Each component plays a critical role in the cable’s performance and longevity.

OPGW cables feature optical fiber units protected by PBT tubes[^7], glass and aramid fiber fabric, aluminum tube sheaths, and aluminum-coated steel wires. This construction provides robust protection and stability for both power and communication functions.

The PBT tubes filled with hydrogen-absorbing gel prevent optical degradation, crucial for maintaining fiber integrity in harsh environments. The glass and aramid fiber fabric offers traction and protects against core displacement, while the aluminum tube sheath and water-blocking gel ensure moisture resistance. Aluminum-coated steel wires[^8] form the structural backbone, providing tensile strength and grounding capability. This multi-layered construction ensures that OPGW cables can withstand mechanical stresses and environmental factors.

Construction Material Breakdown

| Component | Function | Material |

|---|---|---|

| PBT Tubes | Protects fibers from mechanical damage and moisture | Polybutylene Terephthalate (PBT) |

| Glass and Aramid Fiber Fabric | Provides traction and additional core protection | Glass fibers and aramid fibers |

| Aluminum Tube Sheath | Ensures moisture resistance and structural protection | Aluminum |

| Aluminum-Coated Steel Wires | Provides grounding and mechanical strength | Aluminum-coated steel |

How Do Physical Characteristics Affect OPGW Cable Performance?

Physical characteristics such as diameter, weight, and tensile strength are vital for the practical application of OPGW cables. These attributes influence installation, performance, and maintenance strategies.

OPGW cables have diameters from 7.8 mm to over 24 mm and weights ranging from 243 kg/km to over 2157 kg/km, with tensile strengths from 40 kN to over 366 kN. These parameters affect installation methods and system compatibility.

The choice of diameter and weight impacts the ease of installation and the need for specialized equipment. Heavier cables might require reinforced support structures, while lighter cables offer easier handling but might compromise on tensile strength installation methods[^9]. Engineers must balance these factors to ensure that the cables are installed efficiently and perform reliably over their service life. Additionally, tensile strength is crucial for withstanding mechanical stresses, particularly in environments prone to extreme weather or seismic activity.

Physical Characteristics Comparison

| Characteristic | Range | Impact on Performance |

|---|---|---|

| Diameter | 7.8 mm – 24 mm | Affects ease of installation and handling |

| Weight | 243 kg/km – 2157 kg/km | Requires specialized installation techniques |

| Tensile Strength | 40 kN – 366 kN | Ensures cable resilience under mechanical stress |

What are the Electrical and Mechanical Properties of OPGW Cables?

OPGW cables’ electrical and mechanical properties are engineered to support both power transmission and safety requirements. These specifications ensure that the cables can handle electrical loads and mechanical stresses effectively.

OPGW cables typically have an electrical resistance[^10] of 0.49 Ω/km at 20°C, short circuit ratings of 87 kA²s or higher, and initial short circuit temperatures around 35°C. These properties ensure resilience in power transmission applications.

Dive deeper paragraph for H2: The electrical resistance of OPGW cables is designed to minimize power loss during transmission, crucial for efficient energy distribution. Short circuit ratings and initial temperature ratings indicate the cable’s capability to handle sudden electrical surges, which is vital for system stability and safety short circuit ratings[^11]. Engineers must consider these properties when designing systems to ensure that the cables can perform reliably under various electrical loads and conditions.

Electrical and Mechanical Properties Breakdown

| Property | Value | Importance |

|---|---|---|

| Electrical Resistance | 0.49 Ω/km at 20°C | Minimizes power loss in transmission |

| Short Circuit Rating | 87 kA²s or higher | Ensures resilience under electrical surges |

| Initial Short Circuit Temp. | 35°C | Indicates cable’s thermal endurance |

Performance and Environmental Requirements of OPGW Cables

OPGW cables are designed to meet rigorous performance and environmental standards. These requirements ensure that the cables can function effectively in different climatic conditions and maintain long-term reliability.

OPGW cables operate in temperatures from -20°C to +75°C and are classified according to atmospheric discharge standards like Class 1[^12]. Their design life typically ranges from 20 to 25 years, ensuring durability and performance.

The wide temperature range of OPGW cables allows them to be used in diverse environments, from arid deserts to icy tundras. Compliance with atmospheric discharge standards ensures that they can withstand lightning strikes and other environmental stresses atmospheric discharge standards[^13]. The long design life underscores their reliability, making them a cost-effective choice for infrastructure projects requiring minimal maintenance over decades.

Environmental and Performance Specifications

| Environmental Factor | Range | Impact on Performance |

|---|---|---|

| Temperature Range | -20°C to +75°C | Ensures functionality in extreme environments |

| Atmospheric Discharge | Class 1 | Provides lightning strike protection |

| Design Life | 20-25 years | Long-lasting reliability with minimal maintenance |

Installation and Maintenance of OPGW Cables

Proper installation and maintenance are key to maximizing the lifespan and performance of OPGW cables. Detailed planning and specialized techniques help mitigate risks and ensure efficient operation.

[OPGW cable installationhttps://zmscable.es/en/instalar-opgw-cable-fibra-optica/)[^14] involves site surveys, sagging and tension adjustments, and specialized tools for splicing and jointing. These processes ensure the cables are securely and optimally deployed in transmission systems.

Conducting thorough site surveys helps identify potential challenges related to existing infrastructure and environmental conditions. Adjusting sag and tension according to design specifications prevents mechanical stress and potential failures. Specialized splicing tools and weather-resistant sealing methods protect fiber joints, ensuring uninterrupted communication fiber joint protection[^15]. Regular maintenance checks are essential to identify wear and tear, ensuring long-term reliability.

Installation and Maintenance Checklist

| Step | Description | Tools Required |

|---|---|---|

| Site Survey | Identify infrastructure and environmental factors | Survey equipment |

| Sag and Tension Adjustment | Ensure proper cable tension for mechanical stability | Tensioning tools |

| Splicing and Jointing | Secure fiber connections with optimal protection | Splicing tools, weather-resistant seals |

Conclusion

In conclusion, OPGW fiber optic cables are a critical component in modern power transmission systems, offering dual functionality as both ground wires and communication lines. Their diverse fiber types and counts, robust construction, tailored physical and electrical properties, and adherence to performance and environmental standards make them an ideal choice for engineers and managers. By understanding these specifications, professionals in the telecommunications and power industries can make informed decisions that enhance system efficiency and reliability. OPGW cables stand out as a versatile and reliable solution, capable of meeting the complex demands of today’s infrastructure projects.

[1]: Provides a comprehensive understanding of OPGW technology, valuable for professionals selecting cables for specific applications.

[2]: Offers detailed insights into various fiber types available in OPGW cables, assisting in making informed selections.

[3]: Describes G652D fiber specifications, aiding in choosing the correct type for specific transmission needs.

[4]: Provides information on G655C fibers, which is crucial for engineers selecting optimal components for specific transmission needs.

[5]: Explains the properties and suitable applications of OM3 fibers, important for designing high-speed data systems.

[6]: Clarifies the advantages of single-mode fibers like low attenuation, critical for long-distance communications planning.

[7]:Details the use of PBT tubes in cable construction, essential for understanding protection mechanisms in OPGW cables.

[8]: Information on aluminum-coated steel wires is important for understanding the structural integrity and grounding properties of OPGW cables.

[9]: Guides on different installation techniques to ensure optimal deployment and maintenance strategies.

[10]: Explains how electrical resistance affects cable performance, vital for engineering efficient energy distribution systems.

[11]: Important for understanding the cable’s capability to manage electrical surges and maintain system stability and reliability.

[12]: Explains how atmospheric discharge standards ensure that cables can withstand lightning strikes and environmental factors.