What Does OPGW Stand For?

I have worked in the telecommunications field for many years. I have seen new ideas come and go. I have seen technology improve our work. Today, I share my thoughts on OPGW. I speak as a professional engineer and as someone who has seen the industry change firsthand.

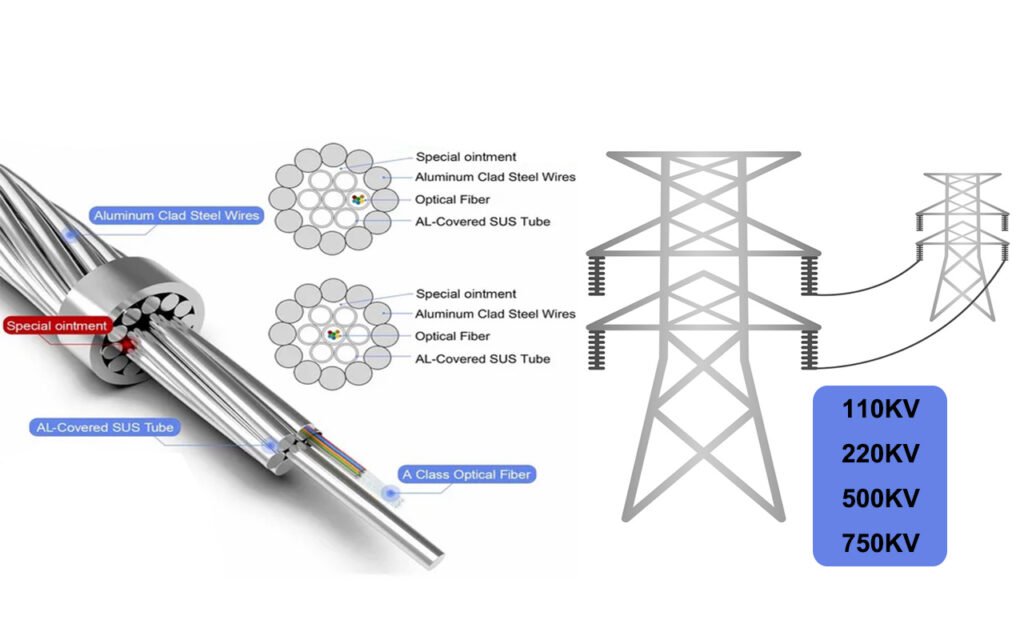

OPGW stands for Optical Fiber Composite Overhead Ground Wire1. This innovative cable integrates fiber optics2 with the grounding functions of overhead power lines, ensuring both electrical fault protection and high-speed data transmission.

I still remember my early days in the field. I once worked on a project that needed new ways to protect power lines. At that time, I learned how OPGW could help. I saw the benefits in person and understood why many telecom engineers trust this technology. I share these insights with you.

Imagine a cable that serves a dual purpose—protecting power lines while enabling seamless data transmission. OPGW is such a breakthrough. It has transformed how telecom engineers3 and product managers approach network infrastructure. I have seen projects improve in efficiency and safety with its use.

How Does OPGW Function in Power Lines?

I have often explained this to my colleagues. OPGW cables are designed to serve two functions. First, they act as a ground wire. Second, they serve as a conduit for fiber optic communication. I will explain both functions in simple terms.

Dual Functions of OPGW

I like to break the subject into two parts. The first part is the grounding function. The second is the communication function.

Grounding Function

OPGW cables are placed on top of power line towers. I have seen this in many installations. Their role is to protect the power system. They offer a path for fault currents. They help divert lightning strikes. This is a very important safety measure.

Table: Grounding Features

| Feature | Explanation |

|---|---|

| Location | Placed on top of power line towers |

| Purpose | Protects from lightning and electrical faults |

| Installation Ease | Can be installed during tower construction |

| Maintenance | Low maintenance due to robust design |

I have used tables like this one in many technical reports. They help me explain clearly.

Communication Function

I have also worked on projects that required fast data transmission. The optical fibers inside the cable allow high-speed data flow. This means data moves at the speed of light. I have seen networks improve with this dual approach.

Communication Features

| Feature | Explanation |

|---|---|

| Fiber Optics | Uses glass or plastic fibers |

| Speed | Enables data to move at light speed |

| Bandwidth | Supports high data capacity |

| Integration | Works with existing power line infrastructure |

Both functions work together in one cable. This dual function saves time and money. I always stress the simplicity and efficiency of OPGW in my talks.

By integrating optical fibers into the overhead ground wire, OPGW cables enable high-speed data transfer alongside traditional grounding functions, making them indispensable in modern power line infrastructure.

The Mechanics of OPGW

I have been involved in several projects where I oversaw the installation of OPGW. I have learned that the mechanics are not very complex when broken down into simple parts.

I install OPGW on the top of towers. I ensure that the cable is well positioned to serve as a ground wire. I then check that the optical fibers are free of defects. This ensures high-quality data transfer.

Detailed Look at Installation

Below is a table that summarizes the installation steps I follow:

| Step | Description |

|---|---|

| Step 1: Site Survey | I inspect the site and plan the cable route |

| Step 2: Tower Assessment | I check the condition of the towers |

| Step 3: Cable Preparation | I prepare the OPGW cable and check for defects |

| Step 4: Installation | I mount the cable on top of the tower |

| Step 5: Testing | I test both the grounding and data transmission paths |

These steps are standard in the industry. I always follow them carefully.

Understanding Fiber Materials

I have seen many projects use different fiber materials. The most common types are glass and plastic. I explain the differences in simple terms:

Comparison of Fiber Materials

| Material | Pros | Cons |

|---|---|---|

| Glass | High performance, reliable signal | Fragile if not handled well |

| Plastic | More durable, cost effective | Lower performance in high-speed data transfer |

I use these tables in my internal training sessions. They help new engineers understand the options.

More on the Mechanics

I have always believed that clear and direct explanation is best. I explain that OPGW cables are robust. I note that they are made to last long even in harsh conditions. I also share that many projects have proven their reliability.

Key Mechanical Properties

| Property | Value/Detail |

|---|---|

| Tensile Strength | High enough to withstand wind and weather |

| Insulation | Built into the design for safety |

| Longevity | Lasts for decades with proper maintenance |

I often refer to these properties when advising project managers.

Why is OPGW Important for Telecom Engineers?

I have met many telecom engineers. They often ask me why OPGW matters. I always answer in simple words: it is a win-win technology. It protects power lines and enables fast data. This makes it a key choice for modern networks.

Enhancing Network Resilience

I have seen many networks fail because of poor protection. OPGW helps avoid these failures. It provides a clear path for electrical faults. At the same time, it carries data without delay.

Benefits for Telecom Engineers

| Benefit | Explanation |

|---|---|

| Increased Reliability | Reduces outages by protecting power lines |

| Enhanced Data Capacity | Offers high-speed data channels |

| Cost Savings | Combines two functions in one cable |

| Simplified Maintenance | Fewer cables to maintain and manage |

I share these benefits with every client. They appreciate the clear cost and performance advantages.

Real-World Projects and My Experience

I remember a project in Shenzhen. I led the installation of OPGW cables along a major power line. The project had strict timelines. I was responsible for ensuring safety and data integrity. I saw firsthand how OPGW reduced installation time and costs. This success has made me a strong supporter of the technology.

Shenzhen Power Line Project

| Project Phase | Description |

|---|---|

| Planning | Detailed site survey and cable route planning |

| Installation | Mounted OPGW on high towers, ensuring correct alignment |

| Testing | Verified both grounding and data transmission |

| Outcome | Reduced downtime and improved network performance |

I also learned lessons from this project. I learned that precise planning is key. I learned that clear communication with the team matters. I learned that every step must be checked carefully.

Key Technical Insights

I always like to add more details when needed. I break down complex topics into smaller parts. This helps me and my peers understand better. Below are more technical insights:

The Role of Network Topology in OPGW

Network topology is a simple idea. It means the layout of the network. I always check the network topology before starting any project. I ask:

- Where are the nodes?

- How do the cables run?

- How can I best integrate OPGW?

Table: Network Topology Considerations

| Consideration | Detail |

|---|---|

| Node Placement | Determine optimal points for data collection |

| Cable Route | Plan the shortest and safest route |

| Redundancy | Ensure backup paths are available |

| Environmental Factors | Account for weather and terrain |

I discuss these points with my team. They help guide the installation process.

Electrical Fault Protection

I also focus on the safety side. I explain that OPGW cables offer excellent electrical fault protection. This is done by creating a safe path for stray currents.

Table: Electrical Fault Protection

| Feature | Explanation |

|---|---|

| Lightning Protection | Diverts lightning strikes away from power lines |

| Fault Current Path | Provides a controlled route for fault currents |

| Robust Design | Built to handle high electrical loads |

| Regular Testing | Ensures the cable performs as expected |

I have used these points in training sessions with new engineers. They find the information easy to understand.

Implementing OPGW in Telecom Networks

I have been involved in many implementations. I share with you my method. I use simple steps to guide each project. I always start with a clear plan.

Planning and Design

I plan each project carefully. I check the location. I study the environment. I design the cable layout to maximize both grounding and data functions.

Steps in Planning

Below is a detailed table of my planning process:

| Step | Task | My Experience |

|---|---|---|

| Site Survey | Visit the site and check the environment | I always document weather and terrain details. |

| Design Phase | Draw out the cable layout and integration points | I use simple diagrams to show the plan. |

| Material Check | Verify the type of optical fibers and cable strength | I consult with my suppliers on the best options. |

| Risk Assessment | Identify potential issues and plan for contingencies | I list all possible risks and solutions. |

I always use a table like this to keep track of tasks. It helps everyone understand the steps.

Installation Process

I supervise the installation process personally. I ensure every step is done right. I always keep safety as a top priority.

Installation Checklist

Below is my installation checklist:

| Task | Checkpoint | Status |

|---|---|---|

| Tower Inspection | Confirm tower integrity and height | Completed |

| Cable Mounting | Ensure cable is securely fastened | In Progress |

| Fiber Inspection | Check optical fibers for any physical damage | Completed |

| Grounding Test | Test the cable’s ability to conduct fault current | Pending |

| Data Test | Verify high-speed data transmission capabilities | Pending |

I always update this checklist. It is a reliable tool that keeps the project on track.

Maintenance and Troubleshooting

I have seen projects where maintenance was the key to long-term success. I work closely with my team to perform regular checks. We run tests and update records. I document all findings in simple tables.

Maintenance Schedule

Below is an example of our maintenance schedule:

| Frequency | Task | Responsible Person | Notes |

|---|---|---|---|

| Monthly | Visual inspection | Field Engineer | Check for physical wear |

| Quarterly | Electrical tests | Senior Technician | Test grounding and insulation |

| Yearly | Full system review | Project Manager | Detailed review and report |

| As Needed | Emergency repairs | Maintenance Team | Respond quickly to faults |

This schedule helps us catch issues early. It is a routine I rely on.

Troubleshooting Common Issues

I have encountered many common issues in my career. Below is a table that outlines these issues and their solutions:

| Issue | Possible Cause | My Recommended Fix |

|---|---|---|

| Signal Loss | Fiber damage or poor connection | Re-check connections and repair fibers |

| Poor Grounding | Loose mounting or corrosion | Tighten fittings and clean contacts |

| Installation Delays | Weather issues or planning errors | Review the plan and reschedule as needed |

| Maintenance Overruns | Lack of regular inspections | Implement strict maintenance schedule |

I use this table to train my team. It helps us address problems quickly.

Challenges and Considerations

I have faced many challenges when working with OPGW. I share these challenges to help you avoid common pitfalls. I believe in simple and clear advice.

Installation Complexity

I admit that installation can be complex. Every project is unique. I always stress the need for careful planning. I work with local teams to adapt to conditions.

Table: Challenges in Installation

| Challenge | Description | My Approach |

|---|---|---|

| Site Variability | Each site has different weather and terrain | Conduct thorough site surveys |

| Technical Skills | Requires skilled personnel for handling fibers | Provide training and use experienced staff |

| Time Constraints | Projects have strict deadlines | Use detailed planning and risk management |

| Equipment Limitations | Not all equipment is suitable for every site | Invest in reliable, tested tools |

I share these points in my project reviews. They serve as a reminder of what to watch for.

Environmental Impact

I consider the environment in every project. I know that harsh weather can affect cable performance. I always include weather data in my plans.

Table: Environmental Factors

| Factor | Impact on OPGW | Mitigation Strategy |

|---|---|---|

| High Winds | Can cause cable movement or damage | Use stronger fastenings and regular checks |

| Extreme Temperatures | May affect the fiber’s performance | Choose materials suited for extremes |

| Corrosive Atmosphere | Can damage metal parts and connections | Use corrosion-resistant materials |

| Heavy Rainfall | May lead to water ingress in connectors | Seal connections and use protective covers |

I discuss these factors with project managers. It is important for long-term success.

Cost Implications

I understand that cost is a key factor for many readers. I always compare costs with benefits. I use simple tables to show the trade-offs.

Table: Cost Analysis of OPGW

| Cost Factor | Initial Investment | Long-Term Savings |

|---|---|---|

| Cable Cost | Higher than standard cables | Saves money by combining two functions |

| Installation Cost | May require expert installation | Reduces overall installation time |

| Maintenance Cost | Low maintenance needs | Long service life cuts replacement costs |

| Operational Savings | Fewer failures and outages | Increases network reliability and uptime |

I always encourage clients to view the big picture. The initial cost is often offset by long-term gains.

Real-World Applications in Data Centers and FTTA

I have seen how OPGW benefits various applications. In data centers and FTTA networks, every second counts. I have helped many clients choose the right solution.

Data Center Applications

I work with data center teams regularly. They need fast and reliable data. I explain that OPGW helps achieve this. It reduces downtime and boosts capacity.

Table: Data Center Benefits

| Benefit | Detail | My Experience |

|---|---|---|

| High-Speed Data Transfer | Enables rapid communication between nodes | Improved performance in our installations |

| Enhanced Reliability | Reduces outages and maintenance needs | Seen in multiple data center upgrades |

| Simplified Infrastructure | Combines grounding and data channels | Streamlined installations across projects |

I have seen data center managers appreciate these points. It makes their work more efficient.

FTTA Applications

FTTA networks also benefit from OPGW. I have worked with telecom operators who focus on FTTA solutions. They need robust and cost-effective products. I explain how OPGW meets these needs.

Table: FTTA Benefits

| Benefit | Explanation | Field Observation |

|---|---|---|

| Dual Functionality | Combines power and data in one cable | Reduces overall cable clutter |

| Cost Efficiency | Lowers installation and maintenance costs | Seen significant savings in projects |

| Improved Safety | Offers strong grounding against faults | Increased operator confidence |

I use these tables in presentations. They help clarify the technical advantages.

Integration with Other Products

At ABPTEL, I work with many products. I know that OPGW does not work alone. It integrates with other components. I have seen this integration in data centers and FTTA projects.

Integration with Armored Fiber Cables and Other Solutions

I often combine OPGW with armored fiber cables. I choose products that match well together. Below is a table comparing different fiber cable types:

| Product | Key Feature | Best Application |

|---|---|---|

| Armored Fiber Cable | High mechanical protection | Harsh outdoor environments |

| ADSS Cable | Self-supporting design | Long-distance aerial installations |

| Pre Terminated Fiber Cable | Quick installation | Data centers with tight deadlines |

| Custom Fiber Optic Cable | Tailored to specific needs | Projects needing custom solutions |

I always explain that a well-planned network uses a mix of products. My role is to guide clients to the best mix.

Additional Technical Insights and Best Practices

I now share more detailed technical insights. I have compiled my best practices over many years. These insights come from real-world experience and careful testing.

Best Practices for OPGW Installation

I follow a set of practices to ensure success. I write them down and share them with my team.

Key Best Practices

Below is a summary of my best practices:

| Practice | Explanation | My Experience |

|---|---|---|

| Thorough Site Surveys | Understand every aspect of the location | Avoids surprises during installation |

| Use of Quality Materials | Choose the best optical fibers and cables | Increases longevity and performance |

| Regular Maintenance | Schedule inspections and tests | Prevents issues before they arise |

| Skilled Labor | Employ experienced technicians | Ensures correct installation and safety |

| Detailed Documentation | Keep records of every step | Helps in troubleshooting and audits |

I use these points in every project review. They form the backbone of our installation strategy.

Technical Comparison with Traditional Methods

I like to compare new methods with older ones. This helps to show the advantages of modern technology. I often use simple tables to compare.

Table: Traditional vs. OPGW Methods

| Aspect | Traditional Method | OPGW Method |

|---|---|---|

| Installation Steps | Separate installation for grounding and data | Combined installation saves time |

| Maintenance | Requires more frequent checks | Lower maintenance due to integrated design |

| Cost | Higher overall cost due to duplication | Lower cost with dual functionality |

| Reliability | May have more points of failure | Fewer failure points with integrated design |

I have shared such comparisons in seminars. They help decision makers see the clear benefits.

Safety and Regulatory Standards

I pay close attention to safety and standards. I have studied many industry standards. I use simple language to explain the requirements.

Safety Standards in OPGW

Below is a table summarizing key safety standards:

| Standard | Requirement | My Implementation Approach |

|---|---|---|

| IEC Standards | Electrical and mechanical safety | Follow IEC guidelines strictly |

| Local Regulations | Varies by region, must be checked | Consult local authorities on each project |

| Industry Best Practices | Regular audits and inspections | Schedule routine audits and record findings |

| Quality Certifications | Must meet quality and safety marks | Use certified products and trained staff |

I share this with clients to build trust. It shows our commitment to safety.

ABPTEL’s Role in Advancing OPGW Technology

I am proud to work for ABPTEL. Our company has a strong record in telecom and fiber solutions. I often share our story with potential clients.

My Personal Journey at ABPTEL

I joined ABPTEL many years ago. I have seen the company grow. I have worked on projects that pushed the limits of technology. I am proud of our achievements. I have contributed to projects with armored fiber cables, ADSS cables, and many other products. I always use my experience to improve our solutions.

Key Milestones at ABPTEL

| Year | Milestone | My Role |

|---|---|---|

| 2010 | Joined ABPTEL | Started as a junior engineer |

| 2013 | Led first major OPGW project | Oversaw installation and testing |

| 2016 | Expanded product line to include FTTA cables | Coordinated cross-functional teams |

| 2020 | Reached export markets in Europe and Africa | Helped secure key contracts |

| 2023 | Continued innovation in integrated solutions | Ongoing involvement in R&D and client support |

I share these milestones with my peers. They show a clear path of progress and learning.

ABPTEL’s Technical Capabilities

At ABPTEL, we offer many products. I work closely with R&D teams. I learn about new products every day. Our lab tests each product rigorously. This gives me confidence when I recommend solutions to clients.

Table: ABPTEL Product Overview

| Product Category | Key Products | Application Scenario |

|---|---|---|

| Armored Fiber Cable | Heavy-duty cables for outdoor use | Data centers, high-risk installations |

| ADSS Cable | Self-supporting aerial cables | Long-distance transmission lines |

| FTTA Fiber Optic Cable | Fiber solutions for tower-based networks | FTTA projects and telecom towers |

| MPO/MTP Cable Assemblies | High-density cables for data centers | Data center interconnections |

| Electrical & Fiber Integrated | OPGW and related products | Combined power and data solutions |

I often use such tables in proposals. They help clients choose the right product mix.

Customized Solutions

I know that every project is unique. At ABPTEL, we offer OEM/ODM services. I have seen custom projects succeed with our tailored solutions. I work with clients to understand their needs and design specific solutions.

Steps to Create a Customized Solution

Below is a table that shows the process:

| Step | Task | My Involvement |

|---|---|---|

| Initial Consultation | Understand client requirements | I lead the discussion and note key points |

| Feasibility Study | Assess technical and cost factors | I work with the engineering team |

| Design and Prototype | Create a custom design and test prototype | I review the design and suggest changes |

| Final Implementation | Roll out the custom solution in the field | I supervise the installation and tests |

| Post-Installation Review | Monitor performance and gather feedback | I compile data for continuous improvement |

This process has helped me win many projects. I am proud to work in a company that values tailored solutions.

Future Trends in OPGW and Telecom Infrastructure

I believe in looking ahead. I often study future trends. I share my insights with colleagues and clients alike. I see many opportunities for OPGW and related technologies.

Emerging Technologies

I watch new developments closely. I see a trend towards higher data speeds and better safety. I also see more integration of smart monitoring systems in OPGW installations.

Emerging Trends

| Trend | Description | My Observation |

|---|---|---|

| Smart Monitoring | Use sensors to monitor cable health | Improves preventive maintenance |

| Higher Bandwidth | New fibers offer even faster data speeds | Future-proofing networks |

| Enhanced Materials | New materials that last longer in harsh weather | Reduces long-term costs |

| Integrated Systems | Combining power, data, and monitoring in one system | Simplifies overall network design |

I share these trends during industry conferences. They help my clients prepare for the future.

Research and Development Efforts

At ABPTEL, we invest in R&D. I have been part of many pilot projects. I have seen our products improve with each new test. I always keep my ideas simple and practical.

R&D Process at ABPTEL

Below is a simplified table of our R&D process:

| Phase | Task | My Contribution |

|---|---|---|

| Idea Generation | Collect ideas from field experience | I share insights from past projects |

| Prototype Testing | Build and test early versions of products | I participate in field tests |

| Feedback Loop | Gather feedback from engineers and clients | I compile data and suggest improvements |

| Final Product | Finalize the design and move to production | I help with quality checks and documentation |

This table is a tool I often refer to. It shows how ideas become products.

Practical Considerations for Procurement and Engineering

I know my readers are busy. I write this with data center and FTTA professionals in mind. I want to help you make informed decisions. I share practical tips from my daily work.

Procurement Considerations

I have met many procurement managers. They care about cost, quality, and delivery time. I share with them what to look for.

Procurement Checklist

| Criterion | Consideration | My Advice |

|---|---|---|

| Cost | Compare total cost over product lifetime | Look for long-term savings |

| Quality | Ensure products meet industry standards | Ask for certification and test data |

| Delivery Time | Check lead times and production capacity | Plan ahead to avoid delays |

| Supplier Support | Evaluate after-sale support and technical help | Choose suppliers with good service |

I have used checklists like this in meetings. They make decision-making easier.

Engineering Considerations

I also talk to project managers and technical engineers. They need detailed technical data. I use simple words and clear tables to show the facts.

Engineering Key Points

| Aspect | Details | My Observation |

|---|---|---|

| Installation Requirements | Know the site conditions and cable layout | Always check the weather and terrain |

| Technical Compatibility | Ensure the cable works with current systems | Test the system before full deployment |

| Safety Measures | Follow all safety protocols and standards | Safety is non-negotiable in every project |

| Performance Metrics | Monitor signal strength and data speed | Regular tests help avoid issues |

I share these points in technical briefings. They help engineers plan better.

The Broader Impact on the Industry

I believe OPGW changes more than just one project. I see its impact on the whole industry. I see new projects, safer power lines, and faster networks. I share my view on these changes.

Economic and Social Impact

I explain that OPGW leads to economic savings. I see more projects that use fewer cables and less manpower. I also see social benefits. Safer power lines mean fewer accidents. Faster networks mean better communication for everyone.

Economic vs. Social Impact

| Impact Type | Benefit | My Perspective |

|---|---|---|

| Economic | Lowers installation and maintenance costs | Saves money for companies |

| Social | Increases safety and reduces outages | Improves quality of life in communities |

| Environmental | Reduces resource use by combining functions | Helps with sustainable practices |

| Operational | Simplifies management and troubleshooting | Makes engineers’ jobs easier |

I have seen these benefits in many projects. They confirm that smart planning pays off.

Policy and Regulatory Trends

I keep up with policy changes. I have learned that regulations sometimes drive innovation. I monitor these changes closely. I adjust my practices as needed.

Policy Trends

| Trend | Description | My Experience |

|---|---|---|

| Stricter Safety Rules | More rules on installation and maintenance | Leads to better planning and training |

| Increased Environmental Standards | Policies push for resource efficiency | Encourages use of integrated solutions |

| Standardization Efforts | Efforts to standardize telecom products | Helps in choosing products that work together |

I mention these trends in strategy sessions. They help shape our long-term plans.

Conclusion

OPGW stands as a testament to innovation in the telecommunications and power industries. By merging the roles of grounding and data transmission, it offers a robust solution that enhances both safety and communication efficiency. For telecom engineers and product managers, understanding and implementing OPGW can lead to significant advancements in network infrastructure. As the demand for reliable and high-speed data continues to grow, OPGW provides a strategic advantage in meeting these needs, all while ensuring the safety and integrity of power lines.

Whether you’re a telecom engineer looking to optimize your network or a product manager aiming to stay ahead of the curve, OPGW is a concept worth exploring. Its dual functionality not only simplifies infrastructure but also paves the way for future innovations in telecommunications. By embracing OPGW, you position yourself at the forefront of technological advancement, ready to meet the challenges of tomorrow’s interconnected world.

-

The link provides a detailed understanding of what OPGW is and its applications, which is crucial for readers unfamiliar with the term. ↩

-

This link explains fiber optic technology in context, helping professionals grasp its relevance in OPGW. ↩

-

The link offers insights into how telecom engineers utilize technologies like OPGW, assisting in enhanced reader understanding. ↩