Are you feeling the pressure to deploy edge computing networks faster? The demand for low latency means traditional on-site installations are too slow, creating bottlenecks. Pre-terminated cables are the answer to this deployment challenge.

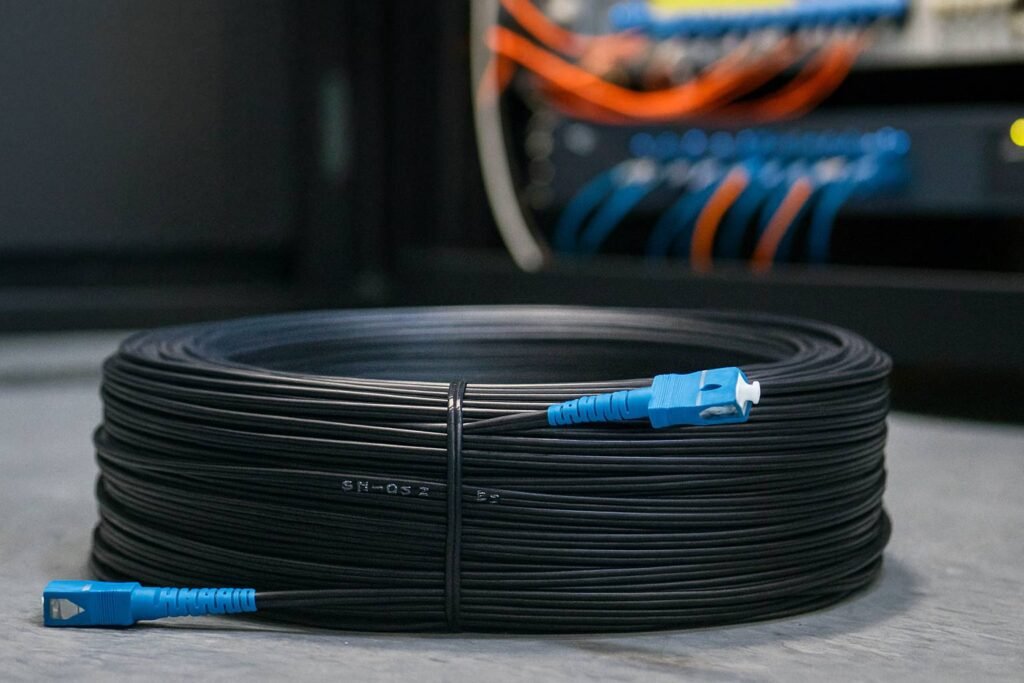

Pre-terminated data center cables are essential because they are built and tested in a factory. They arrive ready to plug in, which drastically cuts installation time, lowers labor costs, and guarantees high performance for fast edge deployments.

I’ve been in the optical communications field for over nine years. I’ve seen many great projects get stuck because of slow, complicated on-site fiber termination. Let me show you how a simple change in cable strategy can get you ahead.

How Do Pre-terminated Cables Actually Reduce Installation Time?

You might be asking how a cable can save so much time. The secret is moving the complex work from the job site into a controlled factory environment.

Pre-terminated cables cut installation time by eliminating on-site splicing and polishing. Technicians simply plug in the connectors. This turns a 15-minute task into a 3-minute one, making your team much more efficient.

Dive Deeper: From On-Site Work to Factory Precision

H3: The Old Way vs. The New Way

With traditional methods, your technician does everything on-site. They have to strip the cable, cleave the fiber, and then carefully fusion splice it. After that, they test each connection, hoping it meets the loss budget. This process is slow and very dependent on the technician’s skill. Any dust or vibration on site can cause a bad connection, leading to more work.

In contrast, we make pre-terminated cables at Abptel in a clean, controlled lab. We use automated polishing machines for a perfect connector surface. We then test every single connector for insertion loss (IL) and return loss (RL) with precise equipment. The cable arrives at your site fully tested and ready to go.

H3: A Practical Time-Saving Comparison

Let’s look at a real-world example. Imagine you need to connect a 96-fiber link for an edge node.

| Task | Traditional Field Termination | Pre-terminated Cable Installation |

|---|---|---|

| Setup Time | 30 – 60 minutes (splicer, tools) | 5 – 10 minutes (cleaners) |

| Termination Time | 10-15 minutes per fiber (x 96) | 1-2 minutes per connector (x 8 MPO) |

| Total Work Time | ~16 – 24 hours | ~1 – 2 hours |

| Rework Risk | Medium to High | Very Low |

The numbers speak for themselves. You save entire days of labor.

H3: The Impact on Your Budget

This time savings directly translates to lower costs. You don’t need to hire as many specialized fiber technicians, whose labor often makes up 30-40% of the deployment cost. You also don’t need to buy or rent expensive fusion splicers and OTDRs for every job site. It simplifies the entire process.

For more strategies on optimizing your cable infrastructure and improving the efficiency of data networks, see our detailed overview of structured cabling and its essential role in data networks.

Is the Quality of Pre-terminated Cables Really Better?

Faster installation is a big win. But you also need to know if the quality holds up. The simple answer is yes, and it’s often much better.

Yes, the quality of pre-terminated cables is consistently higher. Factory environments use precision machines and cleanrooms. This leads to lower signal loss and fewer connection errors than what is possible in a variable field environment.

Dive Deeper: The Technology Behind the Quality

H3: Understanding Key Performance Metrics

Two numbers are very important for fiber optic quality:

- Insertion Loss (IL): This measures how much signal strength is lost when it passes through a connector. In our factory, we can guarantee an IL of ≤0.2dB. It’s very difficult to consistently achieve this in the field.

- Return Loss (RL): This measures how much signal is reflected back toward the source. A lot of reflection can disrupt your network. Our factory polishing process ensures a high RL, meaning a clean signal.

H3: Built with Better Materials

We don’t just assemble cables; we build them with performance in mind. We use advanced materials to protect your data.

- Ultra Low Loss (ULL) Fiber: This type of fiber core minimizes signal degradation over the length of the cable.

- Bend-Insensitive Fiber (BIF): Edge data centers are often crowded with tight cable runs. BIF ensures the signal doesn’t get lost even if the cable is bent sharply.

- LSZH Jackets: In industrial or public spaces, safety is key. We use Low Smoke Zero Halogen (LSZH) jackets. They don’t release toxic smoke in a fire, and they also help shield the fiber from electromagnetic interference (EMI).

For those interested in exploring further, stay informed about top optical transceiver manufacturers that can complement your high-performance cabling solutions.

Final thoughts

Pre-terminated cables are a strategic tool. They speed up deployment, improve network reliability, and prepare you for future growth, making them essential for competing in the fast-paced world of edge computing.