OPGW Cable Selection Guide: Why “Off-the-Shelf” Specs Fail on Transmission Lines

For power design institutes & EPC managers · By Candy @ ABPTEL

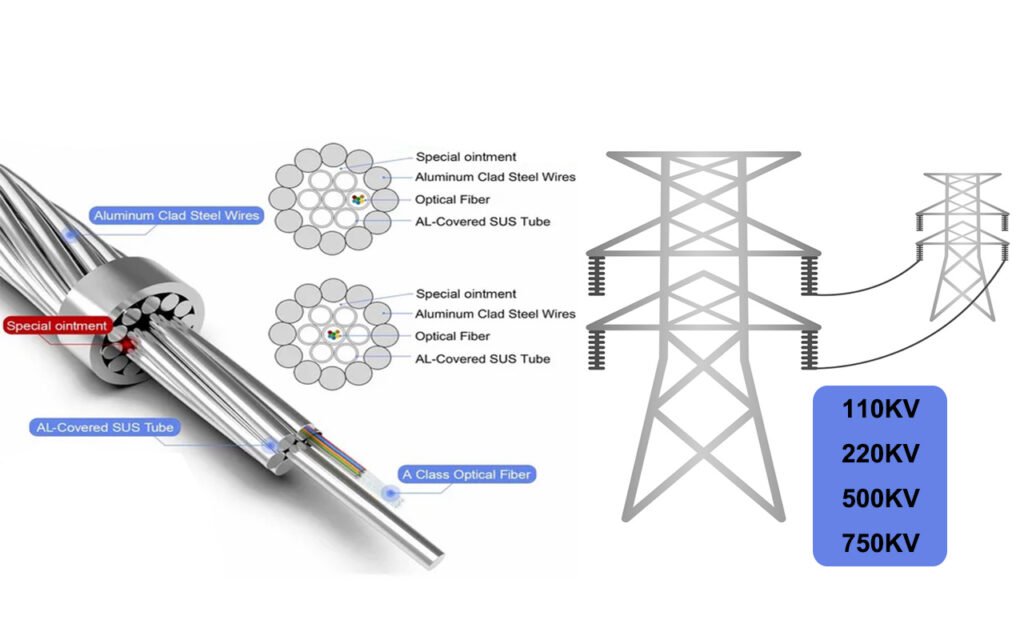

Unlike standard fiber cables, OPGW (Optical Ground Wire) is not a commodity. It is a shield wire that must survive two enemies at the same time:

Mechanical Stress (ice/wind) and Electrical Heat (short-circuit & lightning).

We often receive RFQs asking for a “standard 24-core OPGW price.”

Our answer is always: “Please share your tower and short-circuit data first.”

Choosing the wrong structure—like using a heavy stranded OPGW on an old 110 kV tower—can exceed the tower’s wind/ice allowance.

Ignoring the kA²·s requirement can push the fiber coating above 200 °C during faults, melting fibers.

Below is ABPTEL’s engineer guide to match the right OPGW to your grid—you must calculate, not guess.

Quick Structure Selection (At a Glance)

| Scenario | Recommended OPGW | Key Reason | Typical Fiber Count | Notes |

|---|---|---|---|---|

| Retrofit on old lines (110–220 kV), tight tower load | Central Stainless-Steel Tube OPGW | Smaller diameter & weight → lower wind/ice load | 24–48F | Matches original sag-tension; easier construction |

| New main corridors (220–500 kV), high capacity | Multi-Tube Stranded OPGW (Double-Layer Armor) | More tubes → high fiber count & higher RTS | 96–144F | Better heat dissipation for long spans |

| High thunder density / high short-circuit energy | High Short-Circuit OPGW (Lightning-Resistant) | Aluminum-alloy outer wires ↑ conductivity → less thermal rise | 24–72F | Designed by kA²·s verification (1–3 s faults) |

Scenario 1: Retrofitting Old Lines (The Weight Problem)

When upgrading an existing line (replacing galvanized earth wire with OPGW), the #1 constraint is Tower Load.

Old towers were not designed for heavy stranded OPGW. Extra wind/ice load can exceed safety margins and change sag-tension behavior.

Choose the Central Stainless-Steel Tube OPGW.

- Smaller Diameter → lower wind pressure coefficients.

- Lighter → closer to original earth-wire RTS & sag.

- 24–48F → enough for substation/tele-protection rings.

Scenario 2: New UHV Corridors (The Capacity Problem)

On new 220–500 kV corridors, priorities shift to fiber count, heat capacity and RTS. Central tubes cap out in fiber volume.

✅ Solution: Stranded OPGW

Use Multi-Tube Stranded OPGW (double-layer armor). Stranding multiple stainless-steel tubes delivers 96–144F with robust tensile performance for long spans and heavy icing zones.

Scenario 3: Lightning Zones (The Heat Problem)

The most overlooked parameter is Short-Circuit Energy, often expressed as kA²·s.

When a fault or lightning occurs, OPGW conducts current to ground. Instant Joule heating can raise temperature above 200 °C, degrading fiber coating if conductivity is insufficient.

✅ Solution: High Short-Circuit OPGW with Aluminum-Alloy (AA) outer wires.

AA offers ~3× the conductivity of steel, dispersing heat faster and protecting fibers during 1–3 s faults.

Thermal Check: The One Number You Must Verify

Utilities typically provide fault current and clearing time (e.g., 32 kA for 1 s). Your OPGW must pass the specified

I²·t (kA²·s) without exceeding the allowable temperature rise. Ask for a short-circuit verification sheet during design review.

Don’t Guess Your Specs. Calculate Them.

To issue a valid quote and thermal check, our engineers need:

- Voltage level (kV) & corridor type (new / retrofit)

- Short-circuit current & clearing time (e.g., 31.5 kA · 1 s → 992 kA²·s)

- Required RTS (kN), span length, wind/ice region

- Existing earth-wire data (for retrofit): diameter, mass, sag-tension curve

- Fiber count & routing plan (24F / 48F / 96F / 144F)

We will return a structure proposal (Central Tube / Stranded / High Short-Circuit), thermal verification, and a bill of materials.

Common Pitfalls We See on OPGW Projects

- Ordering “standard 24F” without kA²·s data → fibers damaged after first thunder season

- Picking stranded OPGW for a fragile retrofit tower → wind/ice overload risk

- Ignoring RTS vs. span / ice region → excessive sag or construction failure

- No thermal verification sheet in the submittal package → approval delays

Explore OPGW Options

• Retrofit / light load → Central Tube OPGW

• High capacity corridors → Stranded OPGW

• Lightning / high fault energy → High Short-Circuit OPGW

• More resources → OPGW Category

We validate RTS, kA²·s and sag, then return a stamped datasheet for approval.

OPGW FAQs (Engineers’ Edition)

How do I compare Central Tube vs. Stranded?

Stranded = multi-tube high capacity (96–144F) with higher RTS → better for new long-span corridors.

What is kA²·s and why does it matter?

What data do you need for a formal design?

Can ADSS replace OPGW?