Description

Overview

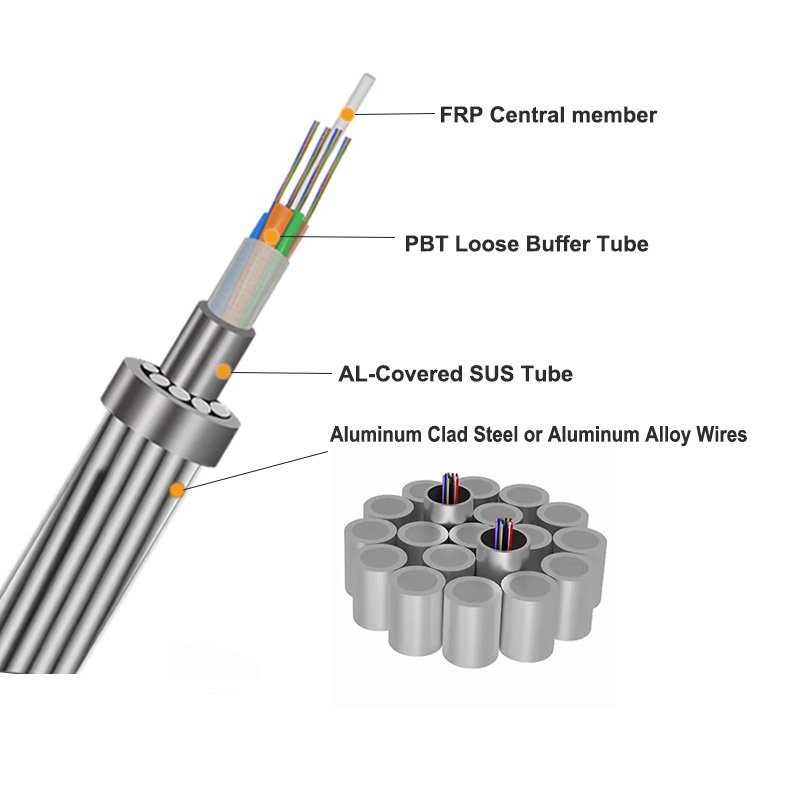

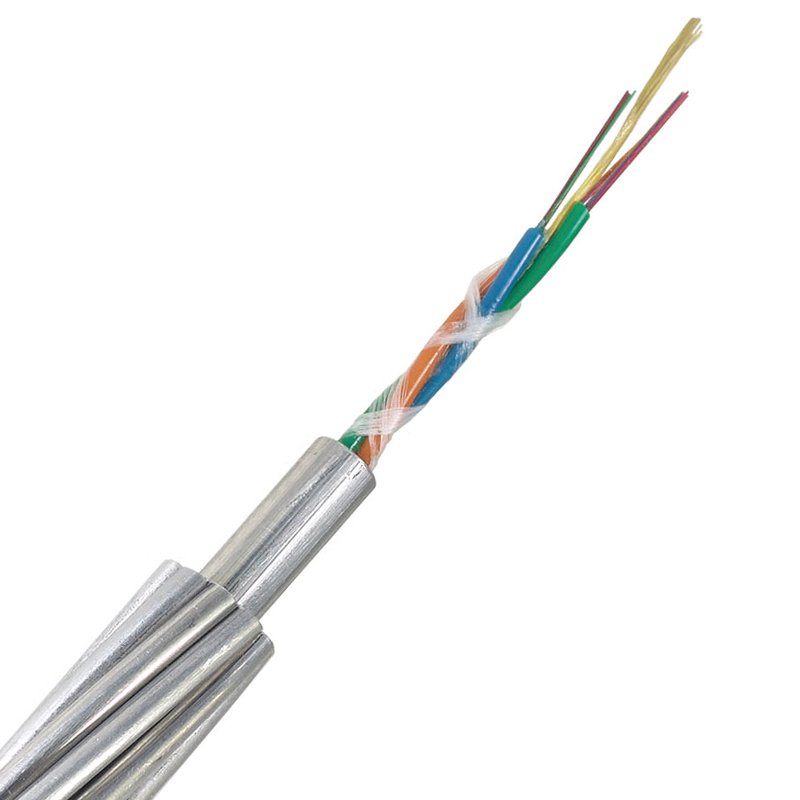

OPGW (Optical Ground Wire) is an integrated overhead cable designed for power transmission lines, combining grounding/shield wire function with optical fiber communication in one structure. With a metallic stranded design, OPGW provides high mechanical reliability and stable performance in harsh outdoor environments, while the built-in optical fibers enable long-distance, high-bandwidth communications for grid monitoring, protection relays, SCADA, and utility telecom networks.

Why OPGW for Transmission Lines

OPGW is typically installed at the top of transmission towers as the ground wire. Thanks to optical fiber’s anti-electromagnetic interference and light weight, the cable can be deployed without complex EMI concerns such as electromagnetic corrosion or optimal mounting position challenges. Meanwhile, the aluminum-clad steel wire design offers excellent conductivity—helping reduce power-frequency overvoltage risks and minimizing the interference and hazardous influence on nearby communication lines.

Key Benefits

- Two-in-one design: grounding conductor + optical communication in a single overhead cable

- Strong & stable: metallic stranded armoured structure improves reliability and firmness

- Excellent conductivity: aluminum-clad steel wires perform as an effective overhead ground wire

- EMI immunity: optical fibers resist electromagnetic interference for stable data transmission

- Utility-ready: supports grid communication, monitoring, protection, and control systems

- OEM customization: fiber count, tube design, RTS, diameter, and short-circuit capacity can be tailored to line conditions

Typical Configuration (Reference Specs)

Below are example configurations for quick comparison. Final design should be confirmed by project requirements (span, RTS, sag-tension, short-circuit current, climate load, and standards).

Example A (From your spec table)

- Model: OPGW-2S 2×12B1

- Fiber: SM G.652D

- Jacket/Cable Diameter: 7.8 mm

- Weight: 243 ± 5 kg/km

- Cross Section: 32

- Cable Length: 3 km/drum

- RTS: 40.6 kN

- Short circuit current capacity: 4.7 kA²s

- Static bending radius: 20D

- Installation temperature: -40°C to +70°C

- Operation temperature: -60°C to +70°C

Example B (From your structure & technical data sheet)

- Cable Type: OPGW-48B1-110 [77.3; 113.1]

- Fiber: G.652D, 48F

- Cable Diameter: 14.8 mm

- Cable Weight: 591 kg/km

- RTS: 77.3 kN

- Short Time Current (1s, 20°C~200°C): 10.6 kA

- Short Time Current Capacity I²t: 113.1 kA²s

- Minimum bending radius: Installation 370 mm / Operating 222 mm

- Temperature range: Installation -10°C~+50°C; Transportation & Operation -40°C~+80°C

- Standards reference: IEC, IEEE, DL/T 832, GB/T 7424.4 (as per your document)

Applications

- Overhead transmission lines (as ground/shield wire with embedded fiber)

- Utility telecom backbone, SCADA communication, and grid monitoring networks

- Substation interconnect and protection relay signaling

- Smart grid upgrades and power line communication infrastructure

OEM / Custom Options

- Fiber type: G.652D / G.655 (and other SM options per project)

- Fiber count: common 12/24/48/72/96F (custom available)

- Mechanical design: RTS, diameter, weight, stranding design, tube structure

- Electrical performance: short-circuit current capacity and conductivity design

- Packaging: drum length, drum type, marking, and documentation support

Quality & Documentation

We can provide standard production documentation upon request, such as test reports, material compliance (e.g., RoHS if required), and traceability records, aligned to the applicable project standards.

FAQ Section

Q1: What is the difference between OPGW and ADSS cable? A1: OPGW contains a conductive metal armor and acts as the grounding wire at the top of transmission towers. ADSS (All-Dielectric Self-Supporting) is metal-free and installed below the power lines, typically used for distribution lines or where the ground wire doesn’t need replacing.

Q2: Do you supply OPGW fittings and accessories? A2: Yes. ABPTEL offers a complete solution including Tension Assemblies (Dead-ends), Suspension Assemblies, Vibration Dampers, Downlead Clamps, and Joint Boxes specifically matched to the OPGW cable diameter and RTS.

Q3: Can ABPTEL customize the Short Circuit Capacity? A3: Absolutely. We adjust the ratio of Aluminum-Clad Steel (ACS) wires to Aluminum Alloy (AA) wires to meet your specific short-circuit current (kA) and duration requirements (I²t) while maintaining the required tensile strength.

Q4: Purchasing Guide: How to Order OPGW?

To receive an accurate quote and technical drawing within 24 hours, please provide the following project details:

- Fiber Count: e.g., 24F, 48F, 96F.

- RTS (Rated Tensile Strength): The mechanical breaking load limit (e.g., 80kN).

- Short Circuit Current Capacity: Critical for electrical safety (e.g., 80 kA²s or 100 kA²s).

- Cable Diameter Limit: To ensure compatibility with existing suspension/tension fittings.

- Fiber Type: Single-mode G.652D is standard; G.655 is used for ultra-long dispersion-shifted links.