Description

Why “High Short-Circuit Capacity” OPGW is a distinct product class

In real power-grid projects, OPGW is not purchased like telecom cable. It is a grid safety component. Beyond carrying fibers for SCADA, protection relays, and monitoring, OPGW must function as an overhead ground wire that:

- Shields conductors from lightning, and

- Conducts short-circuit current during fault events.

When fault current is high (or fault duration is longer), thermal duty becomes a primary risk. Overheating can degrade mechanical strength over time and jeopardize the optical unit. That’s why many utilities specify OPGW by kA²s (short-circuit capacity) in addition to mechanical criteria such as RTS and MAT.

What is kA²s and how it affects the cable design

kA²s is the short-circuit thermal duty index used in OPGW selection. It correlates to how much energy the ground wire must safely carry during a fault event. Higher kA²s generally requires:

- higher effective conductive cross-section,

- improved thermal mass and heat dissipation,

- optimized ACS/AA wire ratios and layer geometry.

ABPTEL engineering approach

ABPTEL designs High Short-Circuit OPGW around four procurement-critical parameters:

- Short-Circuit Capacity (kA²s) — per utility fault study

- RTS (Rated Tensile Strength) — per ruling span and climate load

- MAT (Max Allowable Tension) — typically set around the safe installation/operating range (commonly ≈40% of RTS, but determined by sag-tension rules)

- Span / Ruling Span — section-by-section mechanical constraint

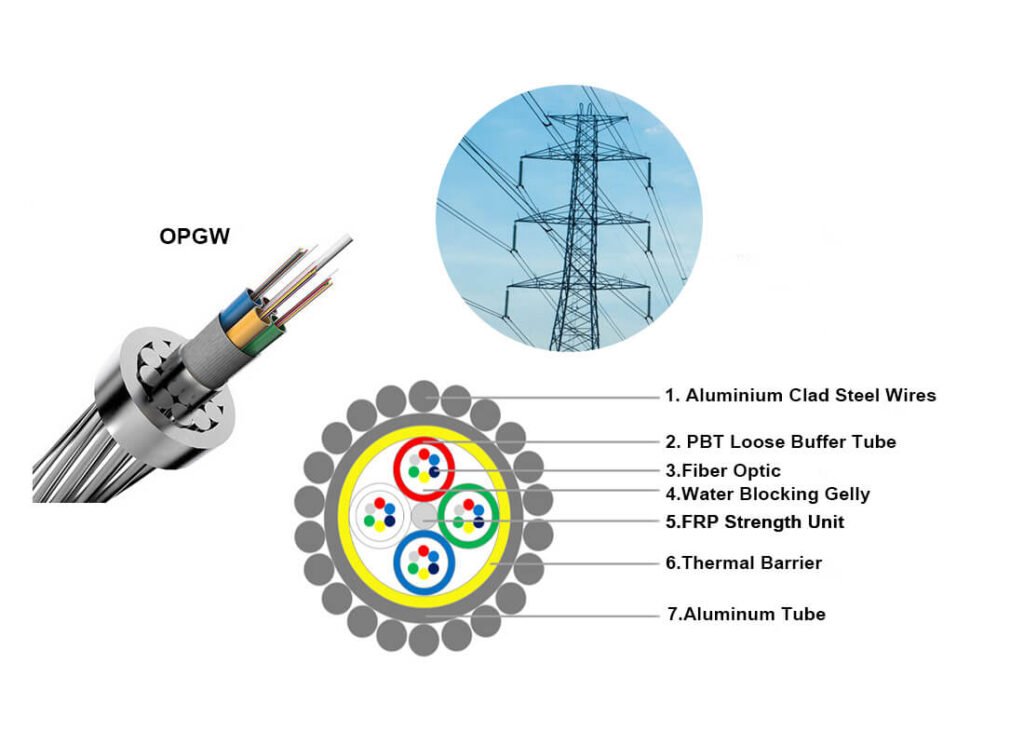

The optical unit is protected inside sealed stainless steel tube(s) filled with water-blocking compound, while the outer layers of ACS/AA conductive wires deliver current-carrying capability and lightning performance.

Typical deployment scenarios

- Substation entrance/exit spans where short-circuit duty is often higher

- Heavy lightning regions requiring robust shielding performance

- Main corridor segments with stricter thermal and mechanical margins

- New 220kV/500kV builds where both kA²s and RTS are explicitly specified in tender docs

Specifications

A) Must-Fill Attributes

| Attribute | ABPTEL Offering | Notes |

|---|---|---|

| Short-Circuit Capacity (kA²s) | Customized (project-specific) | Define by fault current magnitude and duration |

| RTS (Rated Tensile Strength) | Customized (project-specific) | Determined by ruling span + wind/ice + safety margin |

| MAT (Max Allowable Tension) | Typically ≈40% of RTS (customized) | Final MAT follows sag-tension engineering rules |

| Span (m) | Customized by section | Use ruling span; not a fixed “one-size” number |

| Fiber Count | 24–144 fibers (custom) | Based on comm network plan |

| Optical Unit | Sealed stainless steel tube(s), gel-filled | Water-blocking + mechanical protection |

| Conductive Wires | ACS + AA (design optimized) | Balances conductivity and strength |

| Structure | Central tube or stranded multi-tube (project) | High kA²s designs often use robust outer layers |

| Operating Temperature | Typical -40°C to +70°C (project) | Confirm per tender spec |

| Standards (Reference) | IEEE 1138 / IEC (as required) | Provide compliance statement with order |

B) Reference Range

Use this snippet on the page to keep EEAT strong:

Typical engineering ranges (reference only):

- kA²s: commonly engineered in the 80–300 kA²s class for demanding sections (higher available by design)

- RTS: typically engineered in the 60–160 kN class for mainstream projects (higher available by design)

- Final values depend on tower design, ruling span, climate load, and fault study.

If you have your own factory “standard designs,” replace this reference range with your real OD/weight/RTS/kA²s tables for even stronger trust.

Key Benefits

- High kA²s design headroom for severe fault-current duty

- Lightning shielding + fiber communication in one integrated overhead ground wire

- Sealed stainless tube optical protection improves fiber survivability over long service life

- Optimized ACS/AA architecture balances conductivity, thermal behavior, and tensile strength

- Engineering support for tender compliance: kA²s / RTS / MAT / ruling span inputs and documentation package

Applications

- Substation entry/exit sections

- Heavy lightning corridors

- High fault-current duty lines

- 220kV / 500kV transmission routes requiring explicit kA²s specification

- Grid monitoring, SCADA, teleprotection and operational communications

Documentation & Quality

ABPTEL can provide (on request):

- Datasheet and engineered configuration proposal

- Compliance statement to project standards

- Routine inspection checklist, traceability info, and packing documentation

- Pre-delivery test summary (as defined by project acceptance criteria)

FAQ

Q1. When should I specify “High Short-Circuit Capacity” OPGW instead of standard OPGW?

A: When your tender or utility fault study defines higher thermal duty (kA²s) for a line section—commonly near substations, switching nodes, or in corridors with higher fault current risk.

Q2. What information do you need to recommend the right kA²s design?

A: Voltage class, fault current (kA) and clearing time (s), ruling span, wind/ice zone, target RTS/MAT, and required fiber count.

Q3. Does higher kA²s automatically mean larger diameter and heavier cable?

A: Often yes, but not always. Engineering can optimize conductor layer geometry and wire mix to reach the kA²s target while respecting tower loading and sag constraints.

Q4. How do I compare two OPGW quotes fairly?

A: Compare apples-to-apples using kA²s, RTS, OD/weight (kg/km), conductivity/DC resistance, and optical unit construction (sealed tube count and protection).

CTA

Need a datasheet or bid-ready configuration?

Contact ABPTEL to request the PDF datasheet and a tower-section engineering recommendation. Share your required kA²s, RTS/MAT, ruling span, voltage class, and fiber count for an accurate proposal.