Description

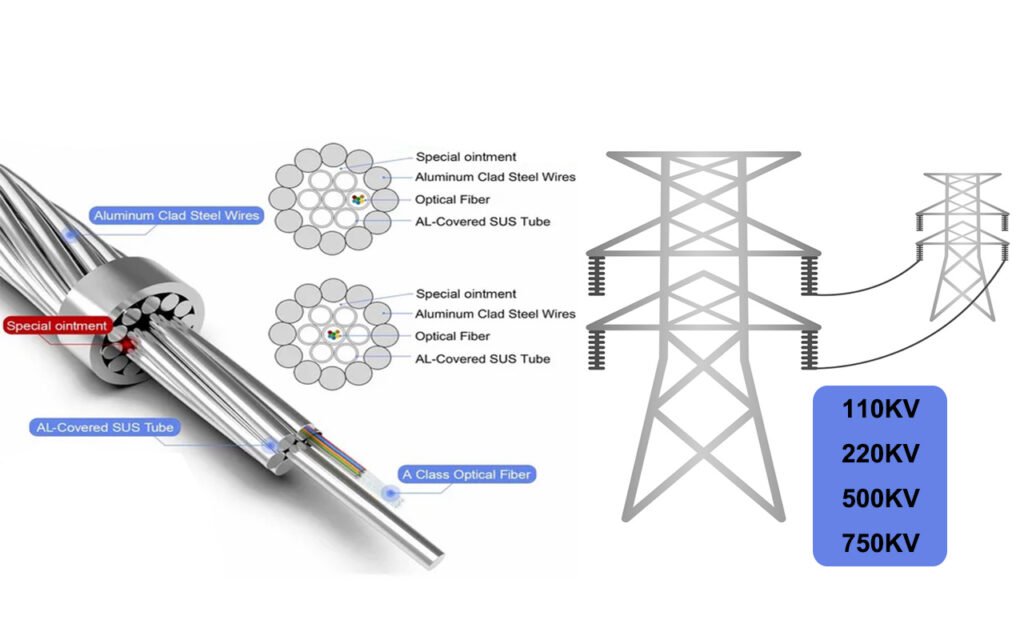

OPGW (Optical Fiber Composite Overhead Ground Wire) combines the function of a ground wire (lightning shielding and fault-current conduction) with optical fiber communication for voice, video, SCADA and grid monitoring.

Central Tube Design

In the central loose tube type, optical fibers are placed loosely in a sealed, water-resistant stainless steel tube filled with gel. The stainless optical tube is located at the center and protected by one or multiple layers of trapezoidal-shaped ACS and AA wires. This compact metallic structure provides:

- High mechanical strength for installation and operation

- Conductivity to control temperature rise during short-circuit conditions

- Smaller diameter with excellent sag-tension performance, ideal for replacing old earth wires

Typical Use Cases

- Old line renovation / retrofit projects

- 66kV / 110kV class lines (project-dependent)

- Fiber counts up to 48 where compact build is preferred

Specifications

| Item | Specification |

|---|---|

| Span | Customized (typical: 150m–350m; per tower section design) |

| RTS (Rated Tensile Strength) | Customized (typical options: 30–90kN) |

| MAT (Max Allowable Tension) | Typically ≈40% of RTS (customized) |

| Short-Circuit Capacity (kA²s) | Customized (e.g., 50–200 kA²s) |

| Fiber Count | 24F / 36F / 48F (typical) |

| Optical Unit | Sealed stainless steel tube + water-blocking gel |

| Outer Wires | ACS (aluminum clad steel) + AA (aluminum alloy) |

| Temperature Range | -40°C to +70°C operating |

| Min. Bending Radius | Installation: 20×OD; Operation: 10×OD (unarmored) / 20×OD (armored) |

Key Benefits

Custom design to match sag-tension limits and kA²s requirement

Compact diameter for retrofit and reduced tower load

Sealed stainless tube for moisture and harsh environment protection

Lightning shielding + short-circuit current conduction (ground wire function)