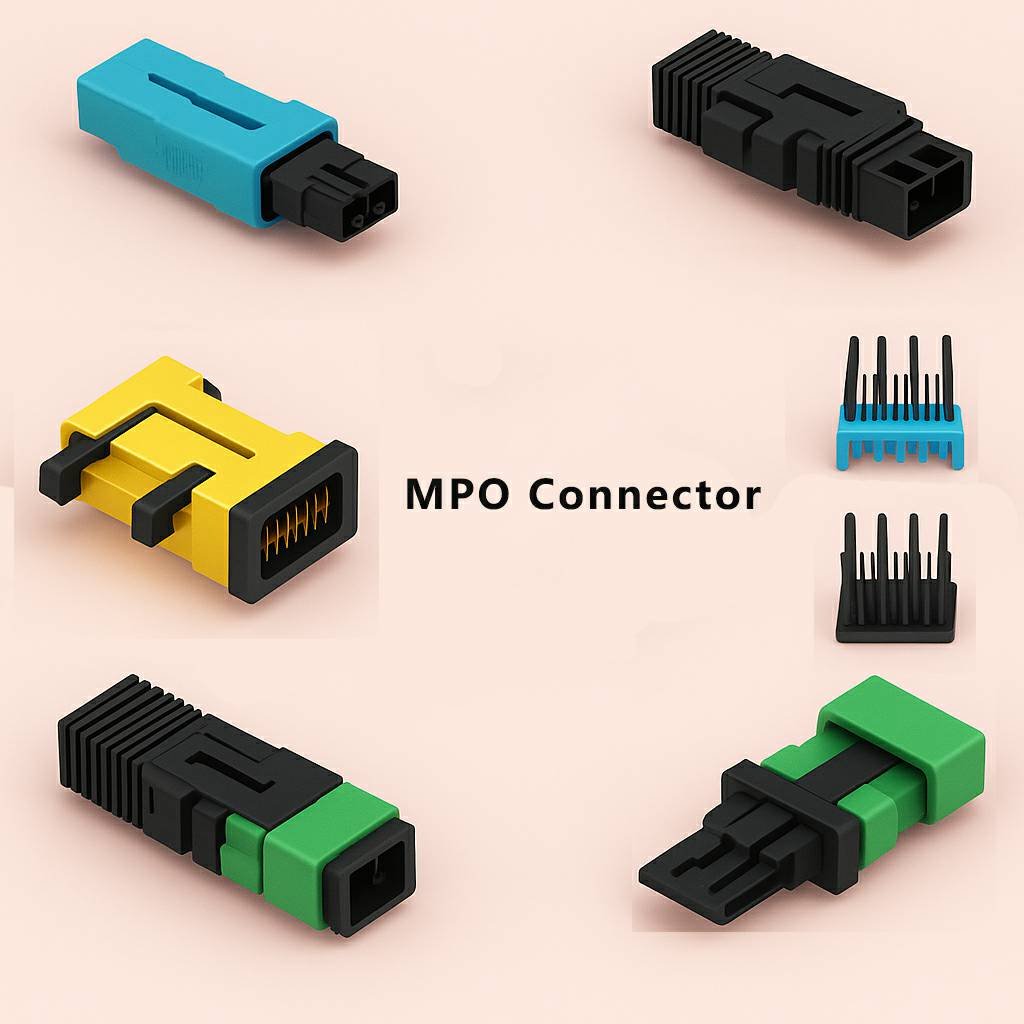

Choosing the right MPO connector is critical for your data center’s reliability. Misunderstanding the core technology, like the difference between V-Groove and MT ferrules, can lead to poor network performance, increased downtime, and higher operational costs. Let’s clear up the confusion.

V-Groove technology offers superior alignment precision and lower insertion loss, making it ideal for performance-critical applications. In contrast, MT ceramic ferrules provide a robust, cost-effective, and more easily maintainable solution for general high-density deployments. Your choice depends on your specific performance requirements, operational environment, and budget.

Over my 9 years in optical communications, I have seen projects succeed or fail based on this one component decision. It is not just a technical detail; it is a business decision. Let’s dig into the facts so you can choose confidently.

How Do V-Groove and MT Ferrule Alignment Mechanisms Actually Differ?

The heart of a connector’s performance is how well it aligns the optical fibers. A tiny misalignment of just one micron can seriously degrade your signal. So, let’s see how these two designs handle this critical task.

V-Groove technology uses precisely etched micro-grooves in a silicon chip to physically guide and align multiple fibers with sub-micron accuracy. MT ceramic ferrules use a simpler system of high-precision guide pins and holes to achieve alignment, which is very robust.

Dive Deeper: Structure and Precision

The fundamental difference lies in their mechanical design. One is about precision engineering on a micro-scale, while the other is about robust, traditional mechanics.

- V-Groove Design: Imagine a tiny silicon chip with perfect V-shaped channels etched onto its surface. The optical fibers rest inside these grooves. This structure holds the fibers in an almost perfect array, allowing for extremely precise alignment when two connectors are mated. Here at ABPTEL, our lab tests confirm this method delivers exceptional stability.

- MT Ferrule Design: This is the more common design you see in data centers. It uses a rectangular ferrule, typically made of a thermoset polymer, with two high-precision metal guide pins. When you mate two MT connectors, these pins slide into corresponding holes on the other connector, forcing the fiber arrays into alignment.

Here is a quick comparison of their design principles:

| Parameter | V-Groove Design | MT Ceramic Ferrule |

|---|---|---|

| Alignment Mechanism | Fibers sit in precisely etched V-shaped grooves. | Metal guide pins fit into holes for alignment. |

| Typical Precision | Extremely high (often ±0.5 microns). | High (precision depends on guide pin/hole tolerance). |

| Primary Material | Silicon or specialized glass. | Thermoset polymer or ceramic. |

For a deeper understanding of related structured cabling, check out what is structured cabling and why is it essential for data networks.

Which Connector Type Offers Lower Insertion Loss?

In high-speed networks, every decibel (dB) of signal loss matters. It can be the difference between a clean signal and a high error rate. Let’s see how these two connector types stack up when it comes to protecting your signal strength.

V-Groove connectors consistently achieve lower and more stable insertion loss, often below 0.2dB, thanks to their superior fiber-to-fiber physical contact. MT ceramic ferrules typically have a slightly higher average loss, around 0.3-0.5dB, but offer reliable performance for most data centers.

Dive Deeper: The Physics of Loss

Insertion loss is primarily caused by misalignment, end-face contamination, and air gaps between fibers.

- V-Groove Performance: Because the V-grooves align the fibers so precisely, there is minimal core-to-core offset. This results in very low signal loss. This design is also less susceptible to changes in temperature, which can cause materials to expand or contract and throw off alignment.

- MT Ferrule Performance: The spring-loaded mechanism in MT connectors ensures firm physical contact. However, the alignment relies on the tolerance of the guide pins and holes. While very good, it is generally not as precise as a V-Groove. This can lead to a slightly higher, but still acceptable, level of loss for most applications.

For more on optimizing performance in high-density networks, you may be interested in optimizing data center high density patch panels.

Final thoughts

V-Groove connectors offer elite precision for specialized tasks, while MT ferrules provide the reliable, cost-effective performance needed for modern data centers. By evaluating your needs for loss, environment, and maintenance, you can make an informed choice. At ABPTEL, we are ready to help you customize the perfect MPO solution.