Description

ABPTEL ADSS Fiber Optic Cable – Short Span 100m, Single Jacket PE, Loose Tube Stranded (12–144F)

Overview

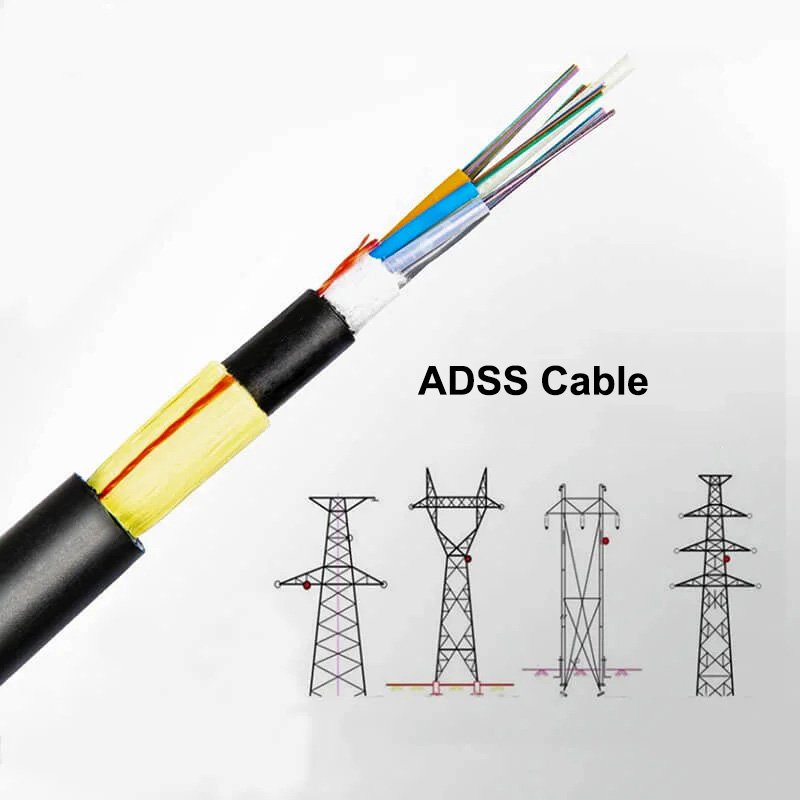

ABPTEL Short Span (100m) Single Jacket ADSS Fiber Optic Cable is engineered for aerial distribution networks where compact size, low weight, and fast deployment matter. ADSS (All-Dielectric Self-Supporting) cable is strong enough to support itself between poles without metallic elements, making it suitable for telecom routes and many power-line corridor builds where dielectric design is required.

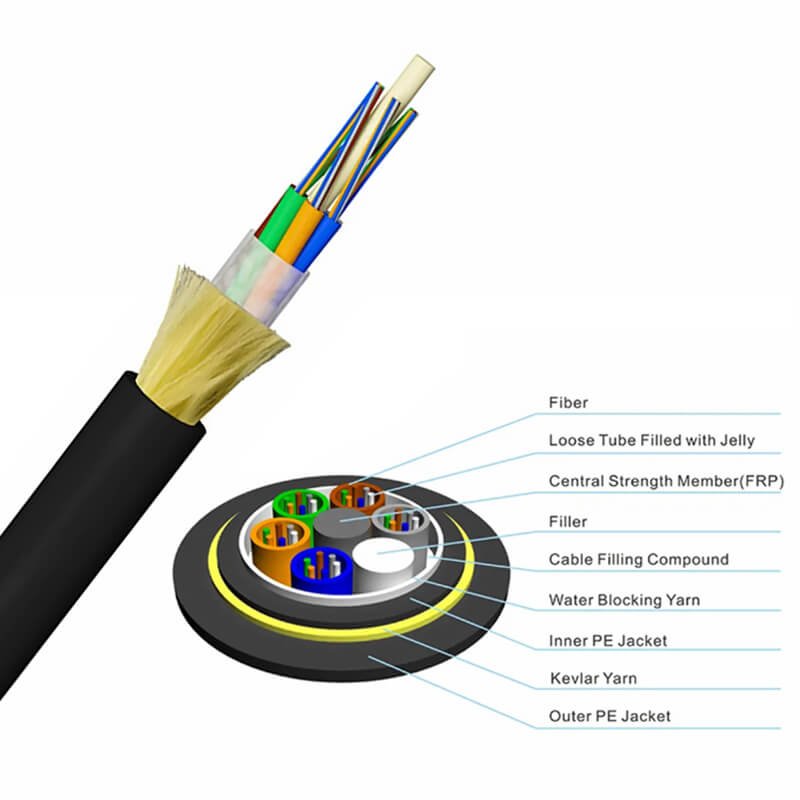

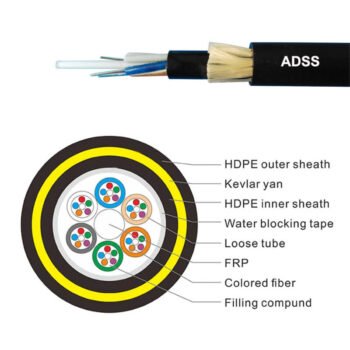

This model adopts a loose-tube stranded construction: 200µm/250µm fibers are placed into high-modulus PBT loose tubes, filled with water-resistant gel, then stranded around an FRP (Fiber Reinforced Plastic) central strength member to form a stable, round cable core. A PE inner bedding / core compound is applied, followed by aramid yarn strength members. Finally, a single PE outer sheath completes the cable, delivering a lightweight structure optimized for short spans.

Why Choose Short-Span ADSS (100m)?

Short-span ADSS is the preferred option for FTTH last-mile and urban distribution where:

- Poles are smaller (wood / concrete) and load margin is limited

- Cable routes require frequent drops and branching

- You want a cost-effective alternative to messenger-wire aerial cables

- The goal is fast installation with reduced hardware complexity

Typical Applications

- FTTH access and distribution optical cable routes

- Urban aerial telecom pole lines

- Campus / industrial park backbone links

- Aerial links between buildings (where span and loading are controlled)

Engineering & Compliance

ABPTEL designs ADSS by matching Span + RTS + MAT + Voltage level + local climate (wind/ice) and installation method. For short span builds, the priority is maintaining safe mechanical margins while keeping cable OD and weight low for easier handling and reduced pole loading.

If you share your span map, wind/ice requirements, and target fiber count, we will provide the recommended RTS/MAT configuration and a matching datasheet.

Fiber Options

- Single-mode: G.652.D (most common), G.657A1 (bend-insensitive options available)

- Multimode: OM2 / OM3 / OM4 (on request)

Packaging & Delivery

- Standard delivery: 3km or 4km per drum (tolerance per production standard)

- Drum size and length can be customized to your project logistics.

Request Datasheet / Quote

To receive the datasheet PDF, test plan, and a quotation, please contact ABPTEL with:

- Fiber count (e.g., 24F / 48F / 96F / 144F)

- Span requirement (confirm 100m or provide route detail)

- Local climate (wind speed, ice load)

- Preferred fiber type (G.652.D or G.657A1)

- Required standards / certificates for your market

Specifications

| ABPTEL Short Span ADSS – Key Specifications | |

|---|---|

| Cable Type | ADSS (All-Dielectric Self-Supporting), Loose Tube Stranded |

| Application | Short-span aerial distribution / FTTH access |

| Span | Up to 100m (typical NESC design conditions) |

| RTS (Rated Tensile Strength) | 6.8kN (typical design; configurable) |

| MAT (Max Allowable Tension) | 2.7kN (≈40% of RTS; typical design; configurable) |

| Fiber Count | 12–144 fibers (common build); other counts available on request |

| Fiber Type | Single-mode G.652.D (default); G.657A1 available |

| Fiber Coating | 200µm or 250µm |

| Loose Tube | PBT, gel-filled water-blocking compound |

| Central Strength Member | FRP (Fiber Reinforced Plastic), dielectric |

| Strength Member | Aramid yarn reinforcement |

| Outer Sheath | PE / HDPE (Black) |

| Cable OD (Typical) | ≈ 10.7 ± 0.5 mm (varies with fiber count/design) |

| Cable Weight (Typical) | ≈ 85 ± 5 kg/km (varies with design) |

| Operating Temperature | -20°C to +65°C (optional -40°C to +70°C upon request) |

| Attenuation (SM Typical) | ≤0.36 dB/km @1310nm; ≤0.22 dB/km @1550nm |

| Water Blocking | Gel-filled loose tubes + water-blocking tape (as required) |

| Standard Drum Length | 3km or 4km per drum (customizable) |

Key Benefits

- Purpose-built for 100m short spans: optimized for FTTH access and urban distribution routes

- Single jacket, lightweight design: reduces wind/ice load on small poles and simplifies handling

- All-dielectric construction: no metallic elements; suitable for mixed telecom/power corridor requirements

- Loose-tube gel-filled water blocking: stable performance for outdoor aerial environments

- Aramid yarn strength reinforcement: reliable tensile performance without messenger wire

- Engineer-friendly selection: Span + RTS + MAT clearly specified for procurement confidence

- Customizable: fiber count, fiber type (G.652.D / G.657A1), drum length, and mechanical design per route

FAQ

What is the difference between short-span and long-span ADSS?

Short-span ADSS is engineered for lower pole-to-pole distances (typically up to 100–150m), prioritizing lightweight design and reduced loading. Long-span ADSS uses higher strength designs (higher RTS/MAT and often different sheath/strength configurations) to handle greater mechanical stress.

Why do RTS and MAT matter when buying ADSS?

RTS (Rated Tensile Strength) indicates the cable’s mechanical capability, while MAT (Max Allowable Tension) defines the safe working tension during installation and service. These values directly affect span feasibility and long-term reliability.

Is PE sheath suitable for outdoor aerial installation?

Yes. PE/HDPE outer sheath is widely used for outdoor aerial telecom routes. If your route is near higher electric field / contamination environments, consider AT (anti-tracking) jacket ADSS instead.

Which fiber types can ABPTEL supply for this ADSS?

Common builds use G.652.D single-mode. G.657A1 (bend-insensitive) is also available, plus multimode options upon request.

Can you customize the design for my local wind/ice conditions?

Yes. Provide your required span, wind speed, ice load, and fiber count. ABPTEL will recommend a matching RTS/MAT design and supply the datasheet and test plan.