Description

One Cable. One Installation. One Complete FTTA Link.

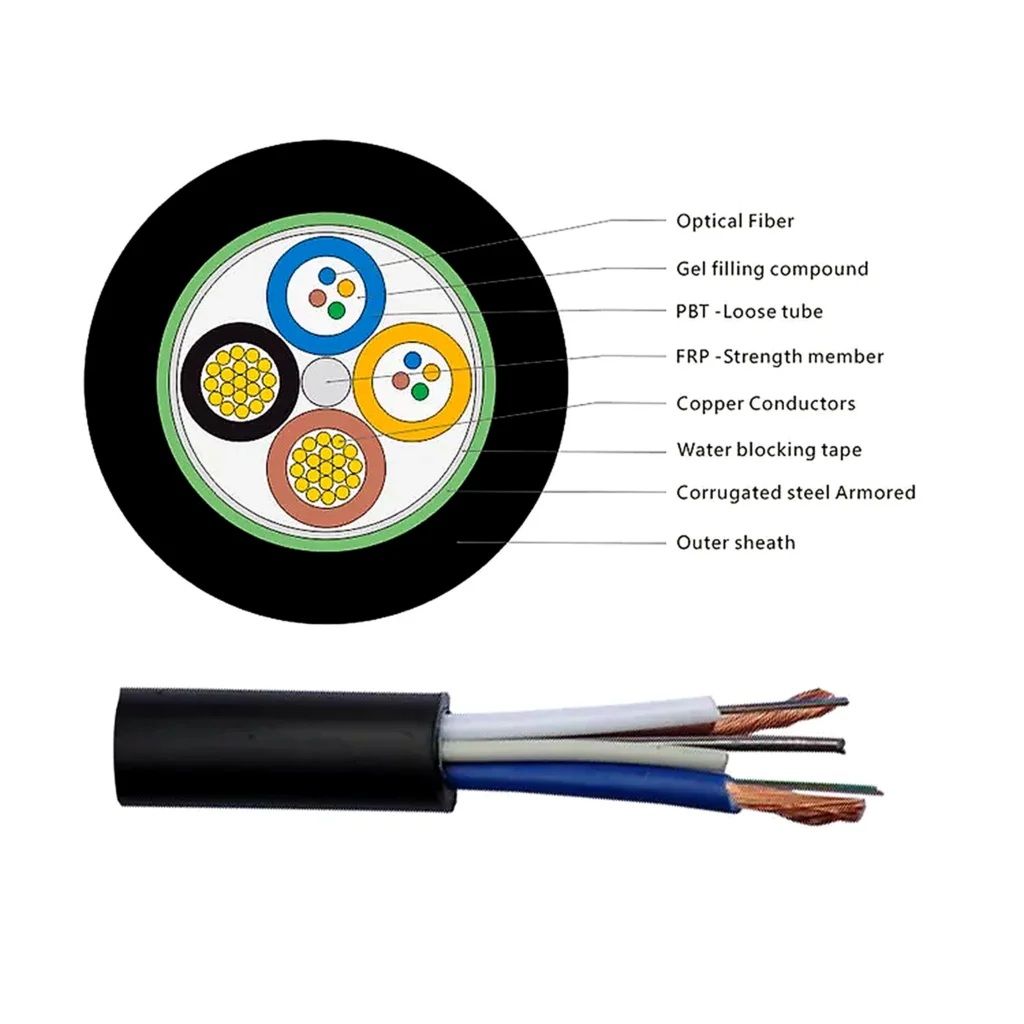

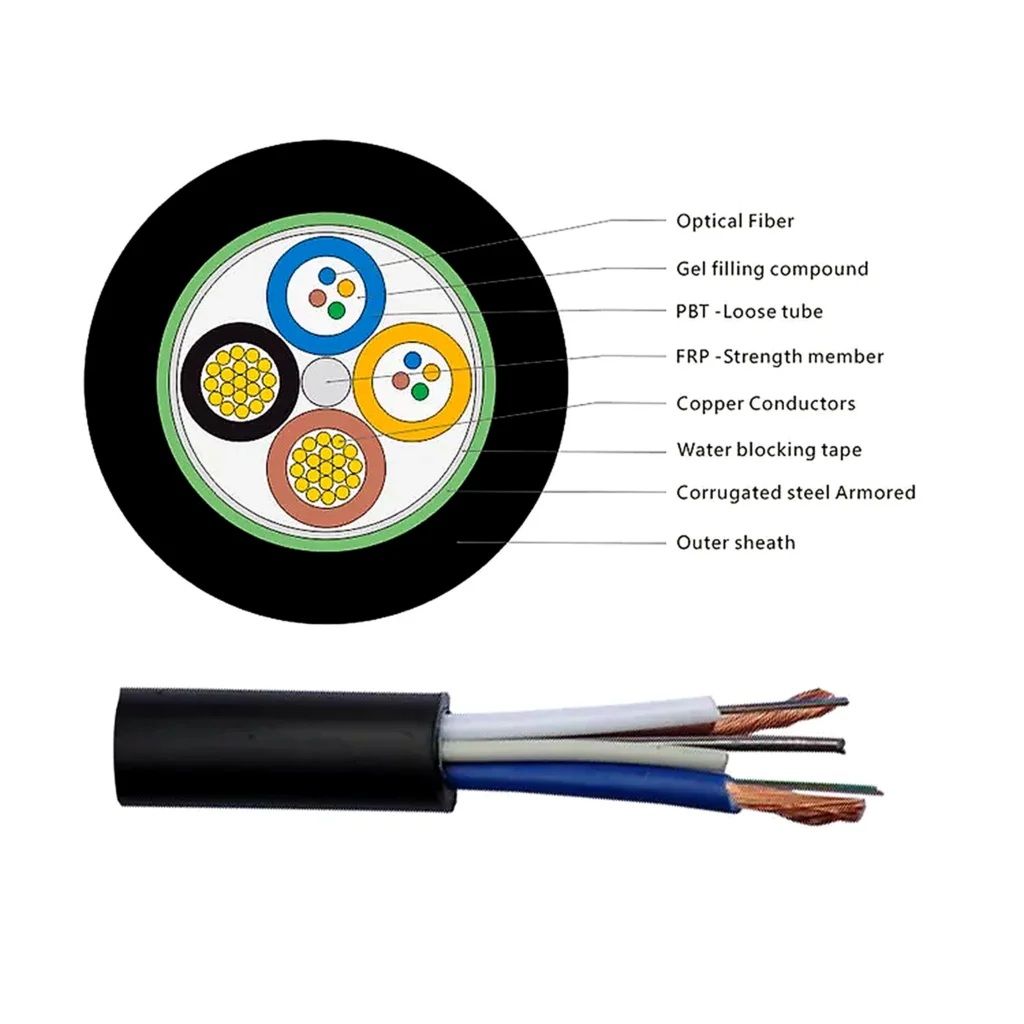

ABPTEL Hybrid Fiber-Optic & Power Cable (GDWC) is engineered for modern FTTA (Fiber-to-the-Antenna) deployments where installation efficiency, structural safety, and long-term reliability are critical. By combining optical fibers for data transmission and copper conductors for DC/AC power into a single armored cable, contractors can complete data + power delivery in one pull.

Why Hybrid Cable Is Replacing Traditional Separate Lines

- 50% Faster Installation: One cable pull instead of separate fiber and power lines.

- Lower Tower Load: Reduced clamps, brackets, and wind load.

- Lower Labor Cost: Especially critical in Europe & North America.

- Cleaner Tower Top: Simplified cable routing improves maintenance safety.

Designed for RRU / AAU Power & Data Transmission

This hybrid cable is widely used to connect BBU to RRU / AAU units on 4G & 5G base stations. The optical fibers ensure stable high-speed fronthaul communication, while insulated copper conductors deliver reliable DC or AC power in harsh outdoor environments.

Rugged Structure for Outdoor & Tower Environments

- Optical Unit: Single-mode G.657A2 fibers optimized for tight bending.

- Power Unit: Shielded stranded copper conductors with stable current capacity.

- Armor: Corrugated steel tape (CST) for crush and rodent resistance.

- Outer Jacket: UV-resistant HDPE for 25+ years outdoor service.

Typical FTTA Applications

- 5G macro base stations (tower top RRU / AAU)

- Urban rooftop base stations

- FTTA retrofit projects replacing legacy separate cables

- High-wind or high-UV outdoor environments

Engineering Note: Fiber count, copper cross-section, armor type, and drum length can be customized based on tower height, power load, and local installation standards.

Technical Specifications

| Item | Specification |

|---|---|

| Fiber Type | Single Mode G.657A2 |

| Fiber Count | 2 – 24 Cores |

| Power Conductors | 2×4 / 2×6 / 2×10 / 2×16 mm² Stranded Copper |

| Voltage Rating | 48V DC / 220V AC |

| Power Conductor Insulation | XLPE / PVC (customizable) |

| Armor Type | Corrugated Steel Tape (CST) |

| Outer Jacket | UV-Resistant HDPE (Black) |

| Operating Temperature | −40°C to +85°C |

| Installation Method | Aerial, tower riser, outdoor routing |

| Drum Length | 500m / 1000m / 2000m (custom) |

✅ Key Benefits

Designed for long-term outdoor FTTA deployment

One-pull installation for fiber and power

Reduced tower load and clamp quantity

Excellent crush and rodent resistance

Stable power delivery for high-consumption 5G AAU

Hybrid cable selection should match both power load and tower routing conditions. Use the guide below to choose the correct copper cross-section, fiber count, and protection level.

🔧 Engineer’s Data Table (Mechanical)

| Parameter | Value (Typical) |

|---|---|

| Tensile Strength (Short Term) | 3000 N (Installation) |

| Tensile Strength (Long Term) | 1000 N (Operation) |

| Crush Resistance | 2200 N / 100mm (Armored) |

| Min. Bending Radius | 20 x Cable Diameter (Dynamic) |

⚠️ Voltage Drop Warning

For runs over 80 meters, typical 2x4mm² copper may cause significant voltage drop (Voltage < 48V at RRU).

Don’t risk power failure. Send us your RRU Power (Watts) & Tower Height. We will calculate the correct copper size (e.g., 2x10mm²) for you.

*Detailed specs including DC resistance available.

Engineering Selection Guide (GDWC Hybrid Fiber-Power Cable)

1) Quick Selection Table

| Deployment Scenario | Recommended Cable Build | Key Parameters to Confirm | Typical Buyer Concern |

|---|---|---|---|

| Standard FTTA macro site (BBU-to-RRU/AAU) | Fiber 2–12C + Power 2×4 / 2×6 mm² + CST armor + HDPE | Tower height, routing length, connector plan | “Will it be fast to install and easy to maintain?” |

| High-power 5G AAU (higher current demand) | Fiber 2–12C + Power 2×10 / 2×16 mm² + CST armor | Power load, DC voltage drop limit, max current | “Voltage drop and heating risk.” |

| Long riser / tall tower (long cable run) | Fiber 4–24C + Power 2×10 / 2×16 mm² + enhanced jacket | Cable run length, bend points, clamp spacing | “Mechanical protection and stable power delivery.” |

| Harsh outdoor (UV, rodent, high abrasion) | CST armor + thick HDPE jacket (UV resistant) | Local UV level, rodent risk, installation method | “Cable damage during pull / long-term aging.” |

| Retrofit / maintenance (fast replacement) | Standard OD + optimized drum length + clear labeling | Required drum length, labeling, delivery timing | “Minimize tower downtime.” |

2) What ABPTEL Needs From You (to engineer the correct design)

- Site type: Macro tower / rooftop / small cell

- Cable run length: total route from power source to RRU/AAU

- Power requirement: voltage (48V DC or 220V AC), max current, allowed voltage drop

- Fiber requirement: fiber count (2–24), fiber type preference (G.657A2 recommended)

- Protection needs: rodent risk, crush risk, UV exposure, routing method

- Termination plan: direct to RRU/AAU, or via an IP68 distribution box / patch panel

Tip for faster quotation: Send your target configuration (fiber count + conductor size) and drum length. ABPTEL can provide a PDF datasheet and an engineered recommendation for your project.

FTTA System Architecture (Hybrid Cable + IP68 Box + Waterproof Patch Cords)

A modern FTTA deployment is no longer just “fiber on a tower.” In 5G builds, the winning architecture is the one that reduces tower climbs, eliminates cable routing errors, and shortens installation time. ABPTEL designs hybrid FTTA solutions as a complete system: one riser cable to carry power + data, a sealed tower-top enclosure for transition, and OEM-compatible waterproof jumpers to feed RRUs/AAUs.

1) Typical 5G FTTA Topology (Recommended)

Step 1: Ground / cabinet area → pull ABPTEL Hybrid Fiber-Power Cable (GDWC) as the riser to the tower top.

Step 2: At tower top → terminate inside ABPTEL IP68 Outdoor FTTA Distribution Box (transition point).

Step 3: Tower top box → connect RRUs/AAUs using ABPTEL Waterproof CPRI / FTTA Patch Cords (FullAXS / PDLC / NSN / ODVA options).

2) Why This Architecture Works (What Contractors Actually Gain)

- Fewer tower climbs: One riser cable reduces routing complexity and rework.

- Less tower hardware: Fewer clamps and brackets compared with separate power + fiber lines.

- Cleaner transition point: An IP68 box protects splices/terminations from water, UV and dust.

- OEM interface compatibility: Matching jumpers prevent connector mismatch and site delays.

3) “Where Each Product Fits” (System Roles)

| System Component | ABPTEL Product | Primary Function | Key Specs to Confirm |

|---|---|---|---|

| Riser (Ground → Tower Top) | Hybrid Fiber-Power Cable (GDWC) | Carry data + power in one pull | Fiber count, conductor size (mm²), armor/jacket, drum length |

| Transition Point (Tower Top) | IP68 Outdoor FTTA Distribution Box (12/24 ports) | Seal and organize terminations/splices | Port count, cable entries/glands, mounting kit, adapter type |

| RRU/AAU Feeds (Tower Top → Radio) | Waterproof CPRI / FTTA Patch Cords | OEM-compatible outdoor connectivity | Connector type (FullAXS/PDLC/NSN/ODVA), cable OD, length, test report |

4) Compatibility Matrix (OEM Interfaces)

Connector interface mismatch is a common cause of site delays. ABPTEL supports mainstream FTTA connector ecosystems:

| Connector Type | Common Usage | Deployment Benefit |

|---|---|---|

| FullAXS | FTTA outdoor radio connectivity | Fast-mate design, stable outdoor sealing |

| PDLC | Outdoor duplex LC style interface | Compact footprint, common in base station retrofits |

| NSN Boot | Outdoor protected LC style interface | Secure retention for harsh tower environments |

| ODVA / ODC | Industrialized rugged outdoor connectivity | High sealing performance, proven field ruggedness |

Practical note: If you are not sure which interface your site uses, send a photo of the existing connector or the radio port label. ABPTEL can confirm compatibility and recommend the correct patch cord type.

5) Typical Project BOM (Bill of Materials)

For a standard FTTA site, the BOM typically includes:

- 1× Hybrid Fiber-Power Cable (GDWC): selected by fiber count + conductor size + drum length

- 1× IP68 Outdoor FTTA Distribution Box: 12 or 24 ports with mounting accessories

- N× Waterproof CPRI/FTTA Patch Cords: quantity equals number of RRUs/AAUs (length and connector type per site)

- Optional: grounding accessories, labeling set, spare sealing gaskets, cleaning tools

6) Internal Links (Recommended for Buyers)

- Waterproof CPRI / FTTA Patch Cords: Use this when the site requires OEM-compatible outdoor jumpers.

- IP68 Outdoor FTTA Distribution Box: Use this when you need a sealed tower-top transition point.

Request a System Proposal (PDF)

Send your tower height, cable run length, fiber count, voltage system, and the required connector interface. ABPTEL will provide a bid-ready system configuration and lead time.

FAQ – Hybrid Fiber-Power Cable for FTTA (GDWC)

1) What is a hybrid fiber-power cable for FTTA?

A hybrid cable integrates optical fibers (data) and copper conductors (power) into one outdoor cable, enabling a single pull installation from the cabinet/BBU area to the RRU/AAU on the tower.

2) Why do many 5G projects prefer hybrid cables now?

Hybrid cables reduce installation steps, clamps, and routing complexity. In high-labor-cost markets, the biggest saving is one pull instead of two, with fewer tower climbs and shorter downtime.

3) What fiber type is recommended for FTTA hybrid cables?

Single-mode G.657A2 is widely preferred because it offers better bend performance, which is important on towers with multiple routing points and tight management paths.

4) How do I choose the correct power conductor size (mm²)?

It depends on your current demand, cable run length, and your allowed voltage drop. For higher-power 5G AAU or longer runs, larger cross-sections (e.g., 2×10 / 2×16 mm²) are typically used.

5) Does the hybrid cable support 48V DC and 220V AC?

Yes. ABPTEL designs hybrid cables for 48V DC (common for RRU/AAU) and can support 220V AC designs depending on your regional standards and insulation requirement.

6) Why is corrugated steel tape (CST) armor important?

CST armor improves crush resistance and helps protect against rodents and accidental damage during pulling and tower routing—common field risks in FTTA installations.

7) Can hybrid cables reduce tower load compared with separate fiber + power?

In many builds, yes. A single hybrid cable can reduce the total number of cables, clamps, and routing hardware, which often simplifies the structure and reduces wind load points.

8) Can I terminate hybrid cables into an IP68 distribution box at tower top?

Yes. Many FTTA architectures use an IP68 enclosure as the transition point. From the box, waterproof patch cords connect to RRUs. ABPTEL can support a full matched set.

9) What tests can ABPTEL provide before shipment?

For fiber, ABPTEL can provide attenuation/continuity verification and documentation as required. For the power unit, conductor checks and basic electrical verification can be provided on request.

10) What information do you need for a fast quotation?

Please share: fiber count, power conductor size, voltage system, cable run length, armor/jacket preference, and drum length. ABPTEL will provide a PDF datasheet and an engineered configuration recommendation.

Request a PDF Datasheet & Engineering Recommendation

Send your required fiber count, power conductor size, voltage (48V DC / 220V AC), and cable run length. ABPTEL will respond with a bid-ready configuration and lead time.