Description

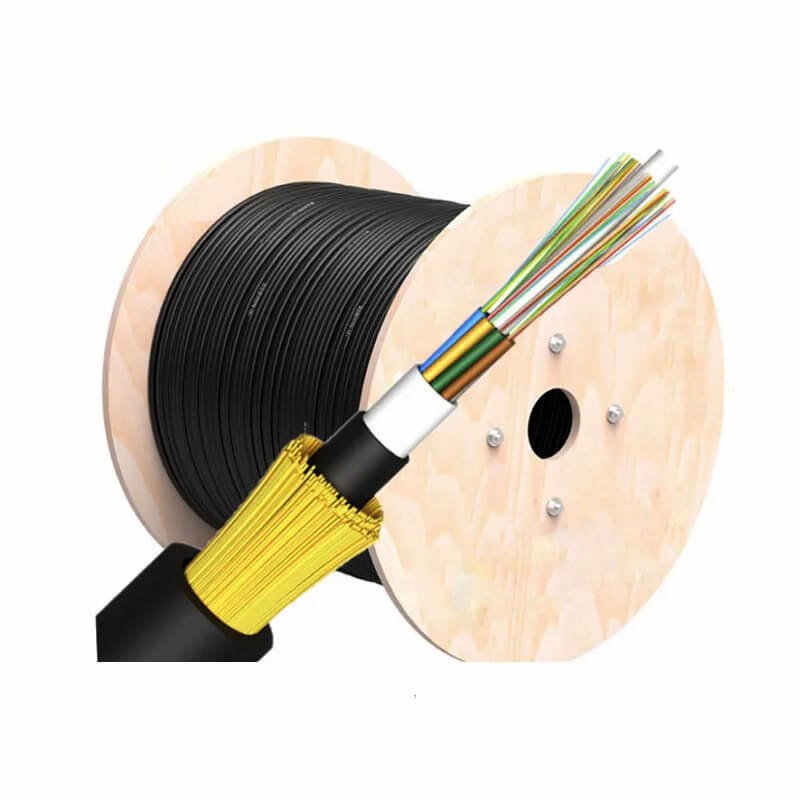

Anti-Tracking ADSS for High-Voltage Power Corridors

Standard PE-jacket ADSS cables can suffer premature jacket damage when installed in strong electric fields on high-voltage towers. In 110kV/220kV environments, contamination (dust, salt fog, industrial pollution) combined with moisture can create conductive paths on the cable surface. This can lead to electrical tracking and dry-band arcing, which progressively burns or carbonizes the sheath.

The ABPTEL AT Jacket ADSS (Anti-Tracking Optical Cable) is purpose-built to mitigate this risk. It uses a specially formulated AT polymer outer sheath designed to resist electrical erosion, significantly improving safety and service life in high-field zones.

What is Electrical Tracking (Dry-Band Arcing)?

Electrical tracking occurs when leakage current flows across a polluted/wet cable surface. As the surface dries unevenly, “dry bands” form, and localized arcing can occur across these dry gaps. Over time, repeated arcing can burn through ordinary PE jackets—leading to sheath failure, water ingress, strength loss, and potential service interruption.

Why Choose ABPTEL AT Jacket ADSS?

- Anti-tracking sheath reduces the risk of surface tracking and arcing damage

- All-dielectric (non-metallic) construction supports safe installation along power lines

- Span / RTS / MAT can be engineered for your tower spacing, route conditions, and mechanical loading

- Suitable for long-term operation in harsh environments (pollution, humidity, UV exposure)

Engineering Note (Important)

Anti-tracking performance depends on space potential, tower geometry, hanging position, climate pollution level, wind/ice load, and installation method. ABPTEL can support selection guidance for AT sheath grade and mechanical design (RTS/MAT/span) based on your route parameters.

Specifications / Attributes

| Item | Specification |

|---|---|

| Span (Recommended) | 100m / 200m / 300m / 400m / 500m / 600m (design-dependent) |

| RTS (Rated Tensile Strength) | 10kN / 15kN / 20kN (typical options); configurable per span & loading |

| MAT (Max Allowable Tension) | ≈40% of RTS (typical engineering practice); configurable |

| Cable Type | ADSS (All-Dielectric Self-Supporting) |

| Key Feature | AT (Anti-Tracking) Outer Sheath |

| Application Voltage Class | 110kV / 220kV transmission corridors (installation position dependent) |

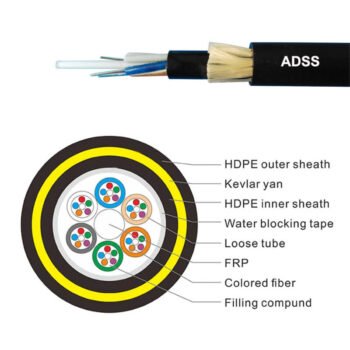

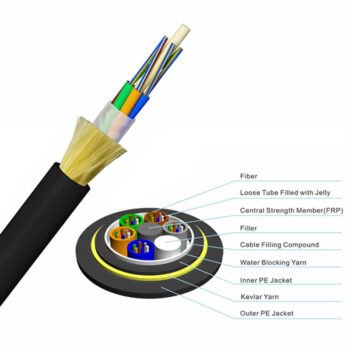

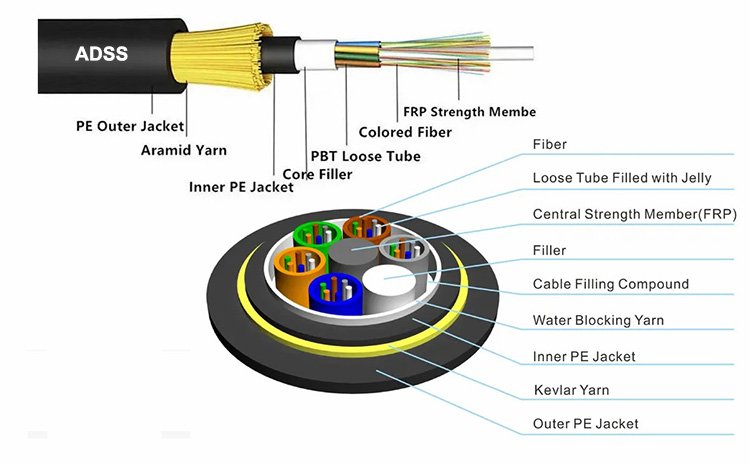

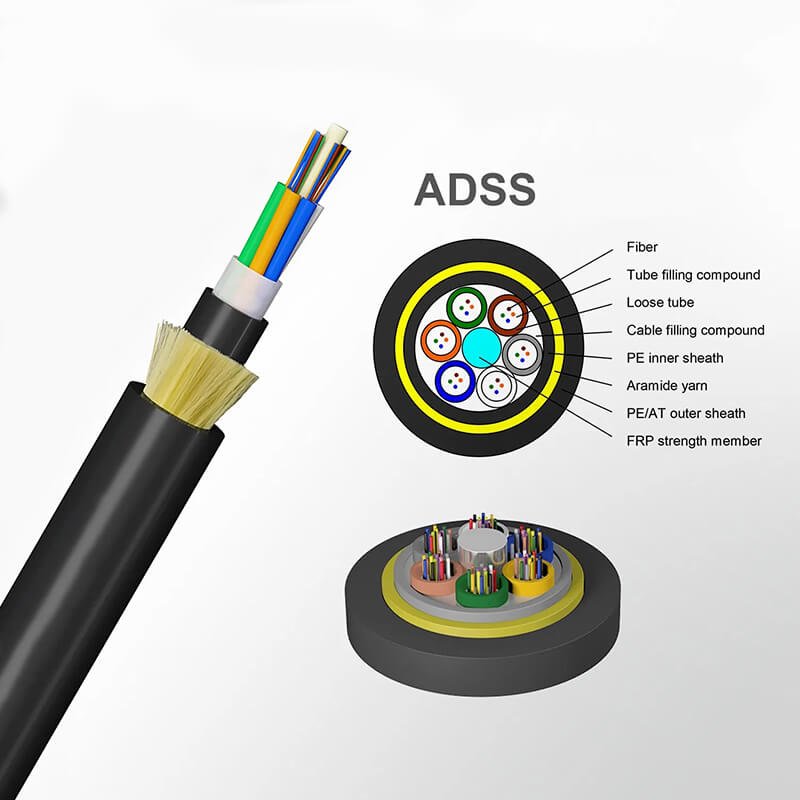

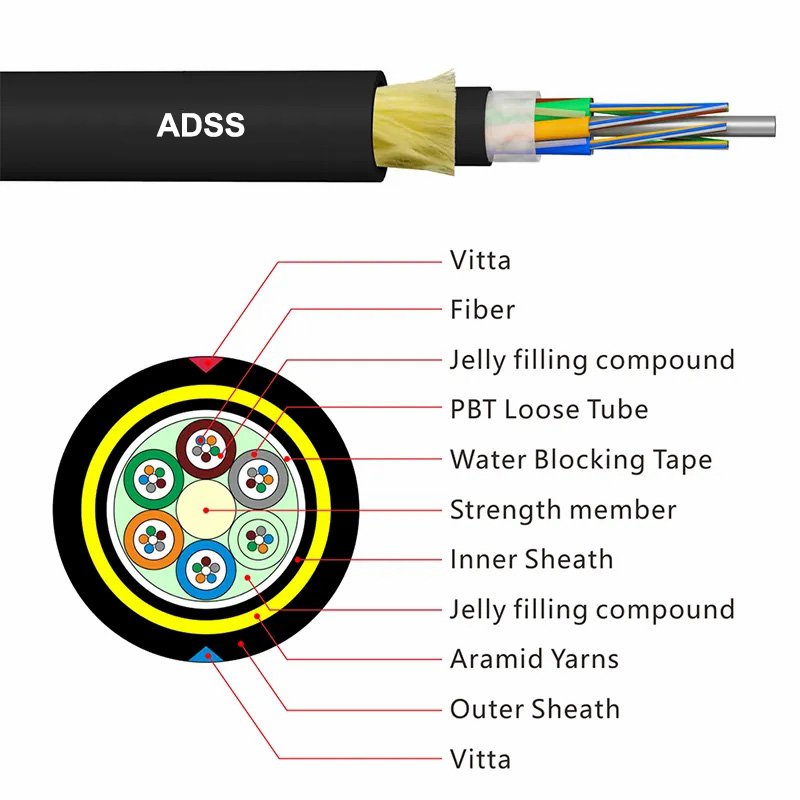

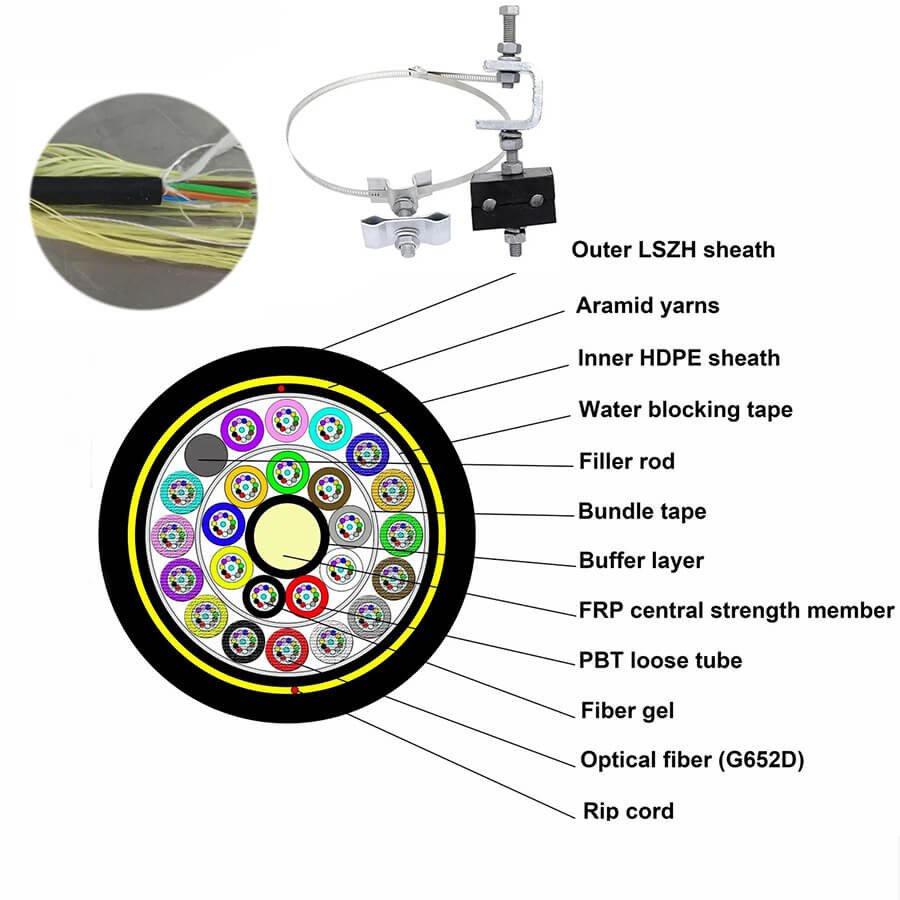

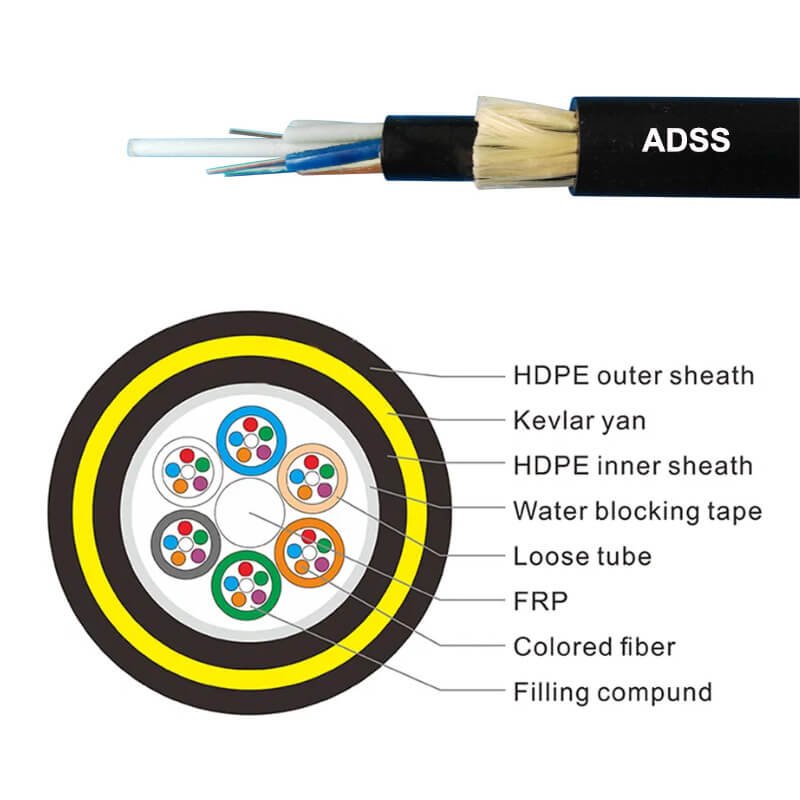

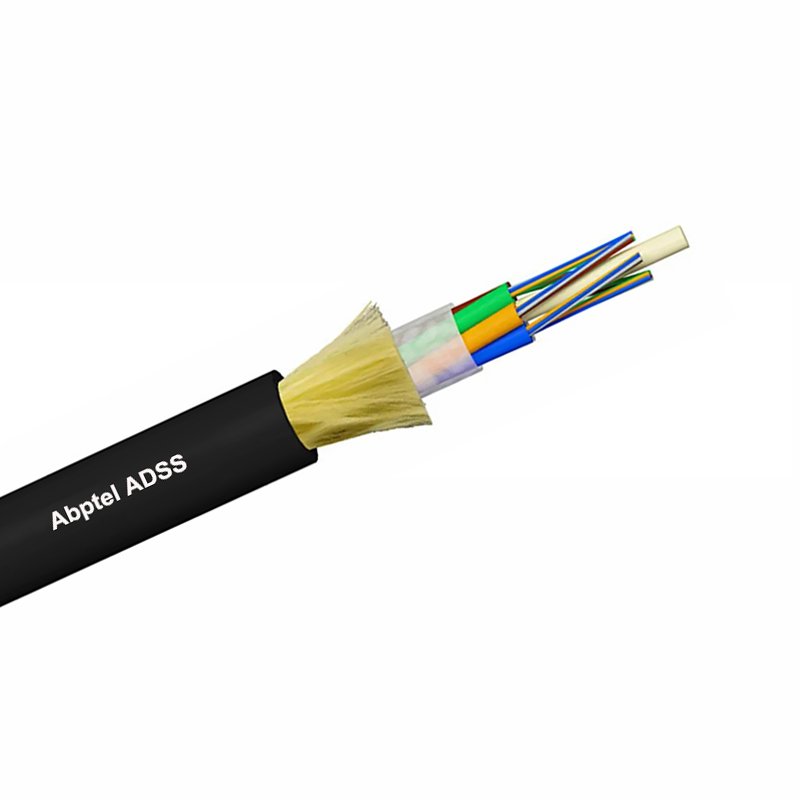

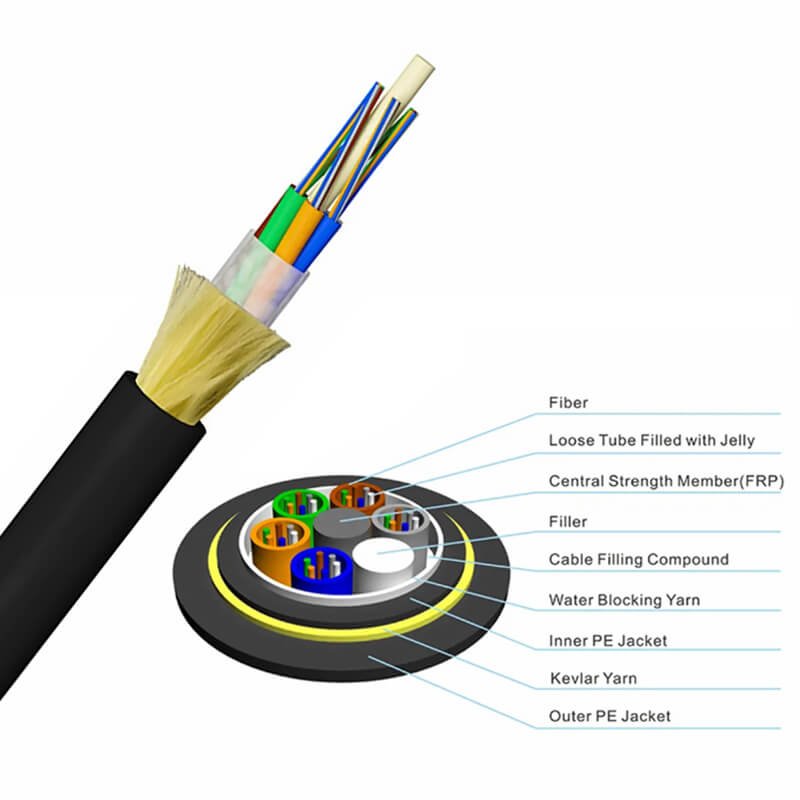

| Structure | FRP central strength member + stranded loose tube + aramid yarn |

| Fiber Type (Options) | G.652.D / G.657A1 / G.655 (others optional) |

| Fiber Count (Options) | 12–144F common; higher counts available by design |

| Water Blocking | Thixotropic gel + water blocking tape/yarn (optional) |

| Outer Jacket | AT polymer sheath, UV resistant |

| Operating Temperature | -40°C to +70°C (typical) |

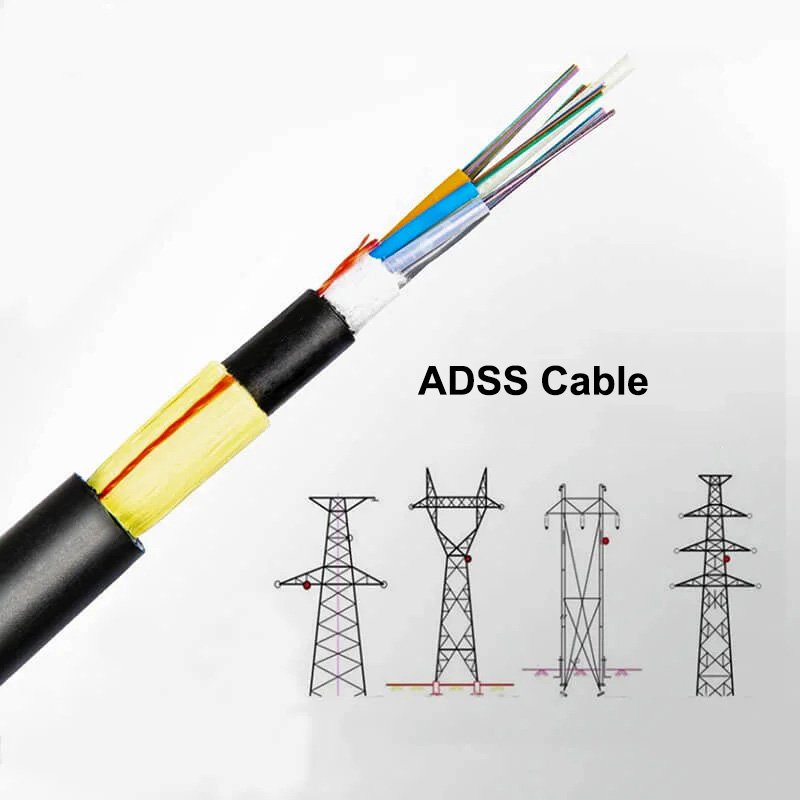

| Installation | Aerial self-supporting, no messenger wire |

| Compliance (Typical) | IEC 60794, ITU-T fiber standards, RoHS (project-dependent) |

Key Benefits

- Anti-Tracking AT Sheath: resists electrical erosion in high-field zones

- Reduces Dry-Band Arcing Risk: improves jacket integrity and long-term reliability

- Designed for 110kV/220kV Towers: suitable for harsh power corridor conditions

- Configurable RTS/MAT/Span: engineered to match tower spacing and climate loading

- All-Dielectric Design: non-conductive, appropriate for utility deployments

- Water-Blocking Loose Tube Core: stable performance in humidity and rain exposure

Application Scenarios

- 110kV/220kV transmission tower aerial fiber routes

- High pollution / coastal / industrial areas (where tracking risk increases)

- Long-term utility communication networks, OPGW alternative routes

- Power corridor backbone links requiring enhanced jacket safety

CTA

Need an AT jacket recommendation for your tower route?

Contact ABPTEL to request the PDF datasheet and share your span / tower type / pollution level / voltage class—we will propose an RTS/MAT/span configuration.