OPGW Cable Manufacturer

OPGW Cable

Reliable OPGW Solutions for High-Voltage Transmission

Engineered for lightning protection and stable communication across 110kV–500kV lines. Backed by strict IEC/IEEE standards.

Abptel, as a leading manufacturer of OPGW (Optical Ground Wire) cables, specializes in providing robust and reliable solutions for high-voltage power transmission lines. Our OPGW cables are produced in our state-of-the-art factory in China, adhering to IEC and IEEE standards to ensure optimal performance and long-term durability.

What Is OPGW?

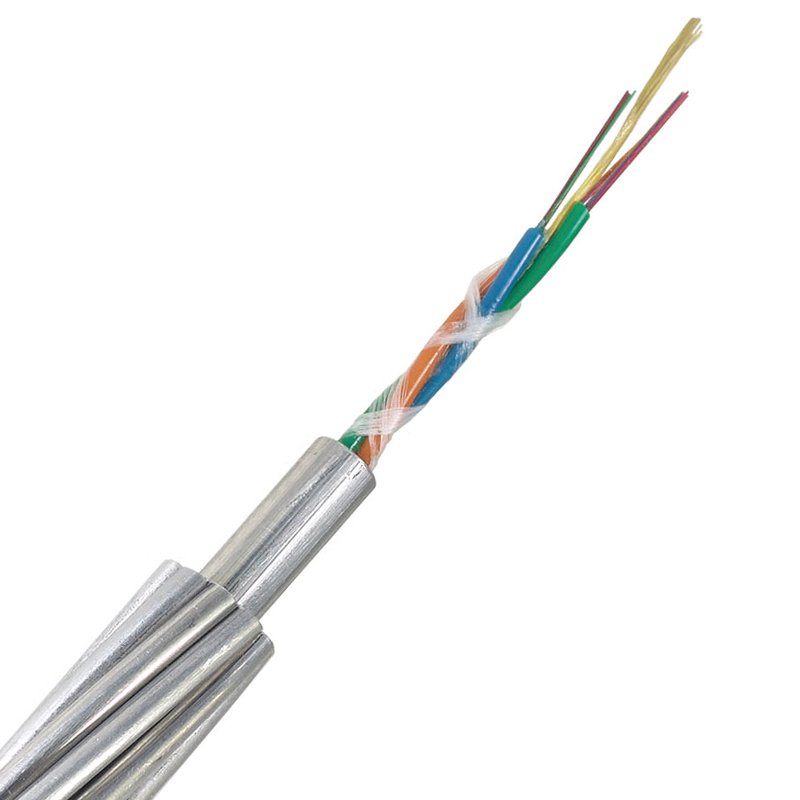

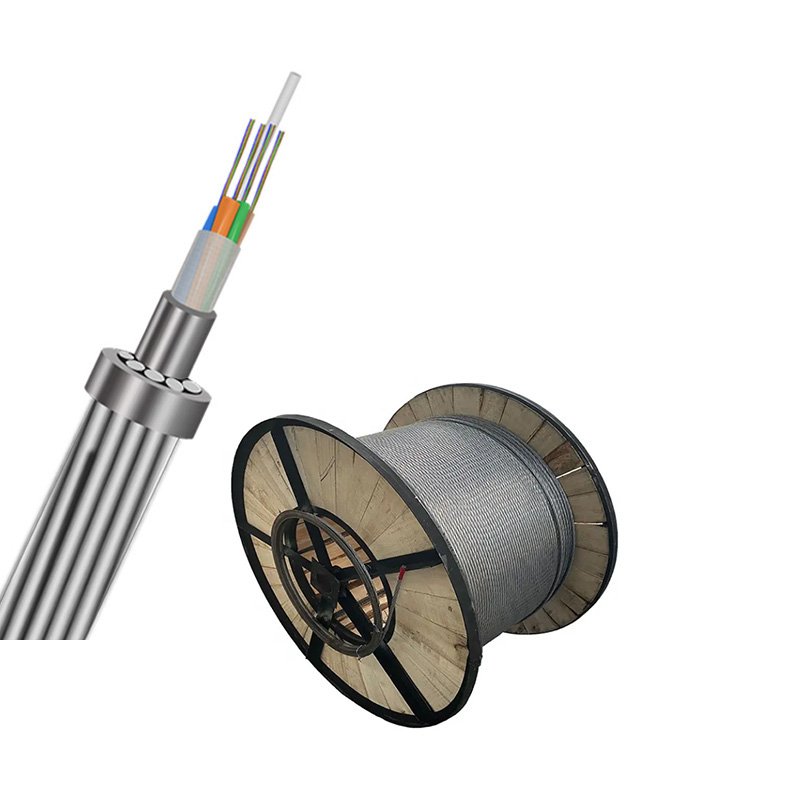

OPGW is a composite cable containing both optical fibers and ground wire conductors. It is installed at the top of overhead power lines to shield against lightning and provide fiber optic communication channels. This dual functionality makes OPGW a cost-effective solution for utility companies, power grids, and telecom operators seeking integrated power and data transmission.

OPGW cables typically offer fiber counts ranging from 6 to 144 fibers. The cable’s outer metal layer serves as a grounding conductor, offering high mechanical strength and lightning protection. It is ideal for harsh environments and long-span installations.

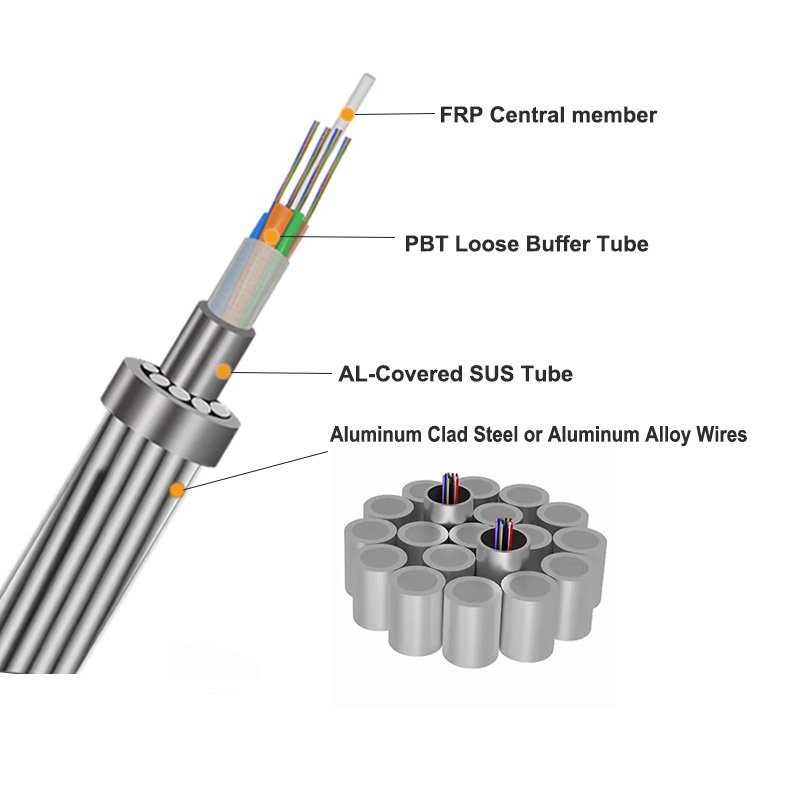

Simplified Cross-Section of an OPGW Cable

A fiber optic cable cross-section showing both metallic strands and internal optical fibers

Optical Fiber Composite Overhead Ground Wire(OPGW)

Optical Fiber Composite Overhead Ground Wire(OPGW) is an Overhead Ground Wire Containing Optical Fibre

Opgw Optical Cable Fiber Optical Cable ISO, SGS Certification

OPGW cable is suitable for installation on new power lines with double function of ground wire and communication

12-96 Core Optical Fiber Composite Overhead Ground Wire

Premium OPGW Factory: 12-96 Core Optical Fiber Composite

OPGW Electric Optical Cable Composite Power Cable With Optical Fiber 12-96core

Fiber Optic Cable OPGW Central Stainless Steel Tube Aluminum Single Mode 24core

Power Aerial Wire 24 / 48 Core OPGW Fiber Optic Cable Single Mode G652d

High quality Power Aerial Wire 24 / 48 Core OPGW Fiber Optic Cable Single Mode G652d

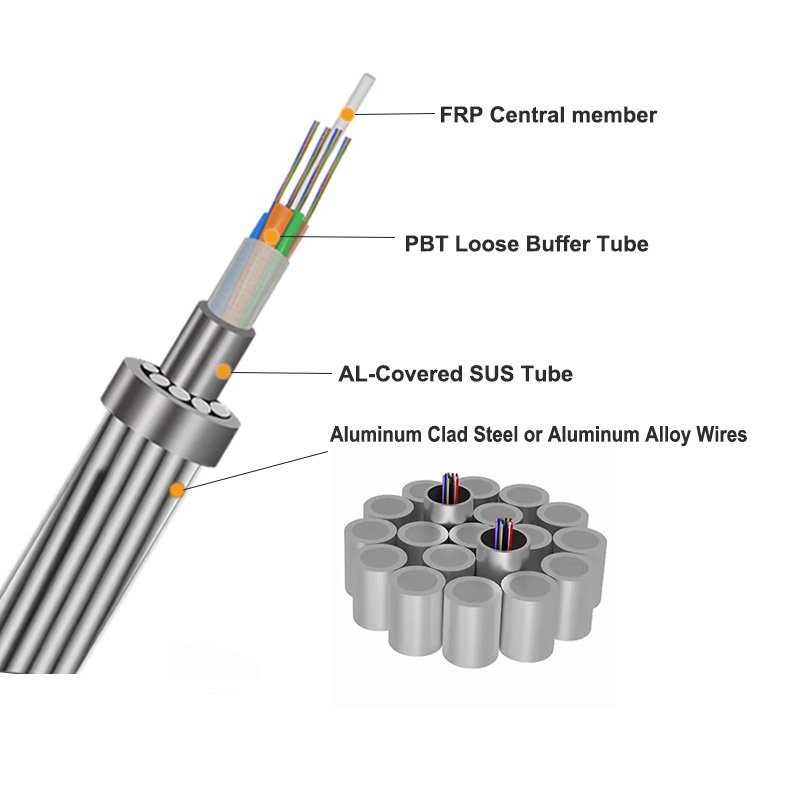

12-96 Cores Central AL-covered Stainless Steel Tube

The central Al-covered steel tube is surrounded by single or double layers of aluminum clad steel wires (ACS)

Aluminium Clad PBT Tube OPGW Cable

The PBT Loose Tube Optical Ground Wire (OPGW) is surrounded by single or double layers of aluminum clad steel wires(ACS) or mix ACS wires and aluminum alloy

Overhead Power Lines 24 Core G652D OPGW Fiber Cable

AlumaCore Optical Ground Wire OPGW Cable 24 Core Single Mode G652D Overhead Power Lines

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About OPGW

Our OPGW cables combine optical fibers and metallic grounding in one single structure. They are engineered to replace traditional overhead ground wires, adding fiber optic communication capabilities while maintaining lightning shielding and fault current grounding for transmission lines.

Fiber Types:

- G.652: Standard single-mode fiber with low attenuation, suitable for most communication needs.

- G.655: Low dispersion fiber for long-distance, high-speed applications.

Fiber Count:

Available from 6 to 144 fibers per cable. Select a fiber count that meets your network capacity and future expansion requirements.

Metallic Wires and Alloy Strands:

OPGW cables typically include aluminum-clad steel or aluminum alloy wires for mechanical strength and electrical conductivity. This ensures both reliable grounding and robust structural support.

Fiber Performance

Cable Performance

| Parameter | Description |

|---|---|

| Breaking Load | Up to 200 kN (varies by cable design and strand type) |

| Short-Circuit Capacity | Designed to handle fault currents for specific durations |

| Attenuation | – ~0.35 dB/km at 1310 nm – ~0.22 dB/km at 1550 nm |

| Temperature Range | – -40°C to +85°C (extended range available) |

Mechanical & Electrical Features

- High Tensile Strength: The cable can support itself across long spans and withstand heavy ice or wind loads.

- Grounding Function: Provides a continuous shield path for lightning strikes, diverting surge current to the ground.

- Easy Integration: Replaces existing ground wire without major modifications to tower design.

- Low Sag & Vibration: Well-engineered cable structure minimizes mechanical stress and ensures long service life.

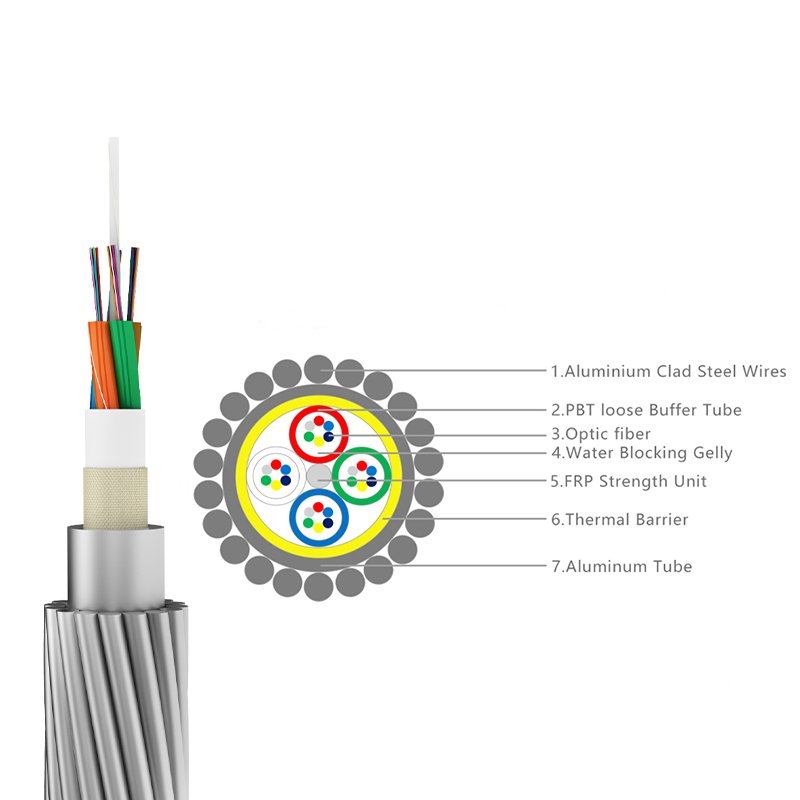

OPGW Structure and Materials

Central Strength Member:

One or more steel or FRP rods to provide tensile strength and core support.

Optical Fiber Unit:

Fibers are loosely housed in buffer tubes, protected by gel or dry water-blocking to prevent moisture damage.

Stranding Wires:

Aluminum-clad steel or aluminum alloy wires are stranded around the central core. This design offers lightning protection, mechanical strength, and current carrying capacity during faults.

Outer Layer:

A smooth, uniform outer surface helps reduce wind resistance and ice loading.

Mechanical Performance

Tensile Strength:

- Ranges typically from 40 kN to 200 kN based on construction and span requirements.

- High mechanical strength for long spans and harsh weather conditions.

Crush & Impact Resistance:

- The metal cladding and stranded wires protect fibers from compression or bending damage.

- Tested to withstand construction-related impacts.

Thermal Rating:

- Short-circuit current rating ensures the cable can carry fault currents without compromising the fibers or the cable’s mechanical integrity.

Considerations When Buying OPGW Cables

When purchasing ADSS (All Dielectric Self-Supporting) fiber optic cables, several key factors should be taken into account to ensure that the product meets your specific requirements. Here, we outline the essential considerations for selecting the right ADSS cables that suit your project needs:

Environmental & Line Conditions

- Voltage Level: Ensure the OPGW design matches your transmission voltage (e.g., 110kV, 220kV, 500kV).

- Span Length: The cable must handle the maximum span between towers under various load conditions.

- Climate Factors: Ice, wind, temperature swings—all can affect cable selection.

Regulatory & Project Requirements

- Utility Standards: Each utility may have its own OPGW specs, certifications, and pre-qualification processes.

- Fault Current Duration: Cable must safely carry short-circuit current for the specified time.

- Compliance: All Abptel OPGW cables adhere to IEC, IEEE, and ISO standards.

OPGW Cable Quality Control and Testing

- Optical Performance: Attenuation and bandwidth tests for each fiber.

- Mechanical Strength: Tensile, crush, and vibration tests to verify cable integrity.

- Electrical Conductivity: Short-circuit current and grounding path evaluations.

- Environmental Simulation: Temperature cycling and humidity resistance tests for harsh climates.

We provide detailed test reports upon request, ensuring full transparency for your project requirements.

Other Questions When Buying ADSS Cables

OPGW Cable

- All-In-One Solution: Offers both grounding protection and fiber communication in a single cable.

- High Reliability: Metallic layers shield the cable from lightning and electrical faults while protecting internal fibers.

- Long Service Life: Durable construction suited for high-voltage and extreme environmental conditions.

OPGW Cable

Advantages of OPGW:

- Integrated Ground Wire: Replaces the existing shield wire, adding fiber without additional lines.

- Superior Lightning Protection: Metal cladding and armor effectively ground lightning strikes.

- Higher Mechanical Strength: Designed to handle more severe mechanical loads in high-voltage corridors.

Advantages of ADSS:

- All-Dielectric: No metal, so no risk of induced currents—simpler installation in certain scenarios.

- Lightweight: Easier and faster deployment where ground wire replacement isn’t feasible.

CONTACT US

Need any urgent help? to hire us now!

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Call For Booking

+86 18814455697

Have A Questions ?

Candy@abptel.com

Location Address

5/F, Building 10, Tangwei Cuihai Industrial Zone, Fuyong Town, Baoan District, Shenzhen