How Do You Choose the Right OPGW Cable?

Choosing the right Optical Power Ground Wire (OPGW)1 cable can be daunting for telecom engineers and product managers. Without the right considerations, you might end up with a cable that doesn’t meet your needs, leading to inefficiencies and increased costs. But don't worry, here's how to make the right choice.

To choose the right OPGW cable, consider factors like your specific needs for transmission speed, distance, and environmental conditions. Evaluate the manufacturer’s reputation2, material, type, and electrical parameters of the cable. Assess its mechanical strength, compatibility with existing infrastructure, ease of installation, and adherence to international standards.

Navigating the complex world of OPGW cables requires more than just technical know-how; it involves understanding your unique needs and how these cables can address them. Imagine being a telecom engineer tasked with ensuring seamless communication across rugged terrains. The right OPGW cable is your lifeline, and here's how to secure it.

What Should You Know About Your Needs?

Before diving into the sea of options, it's essential to clarify your specific requirements. You wouldn’t buy a car without knowing your driving needs, right? The same logic applies here.

Understanding your needs involves evaluating parameters like transmission speed, power capacity, distance, and the number of optical fibers required for both current demands and future expansions. This helps in narrowing down choices effectively.

Transmission Speed and Bandwidth

The speed at which data needs to be transmitted is a crucial factor. High-speed data transmission may require a cable with more optical fibers or higher bandwidth capabilities. Consider future scalability too, ensuring the cable can handle increased data loads over time.

Power Voltage and Current Capacity

Assess the power requirements of your infrastructure. An OPGW cable must handle the necessary voltage and current without compromising performance. This ensures stable power delivery alongside data transmission.

Distance and Future Capacity

The distance the cable needs to cover influences your choice. Longer distances may demand cables with specific attenuation properties to maintain signal integrity. Additionally, consider future capacity needs to avoid frequent upgrades.

How Do You Choose a Reliable Manufacturer?

Selecting a reputable OPGW cable manufacturer is akin to choosing a trustworthy partner. It can make a significant difference in product quality and overall satisfaction.

Choose a manufacturer with a strong reputation for quality and customer service. Research through reviews, feedback, and professional consultations to ensure you’re partnering with a reliable provider.

Importance of Reputation

A manufacturer with a proven track record assures you of the cable's quality and durability. Look for companies that have consistently delivered reliable products and services over the years.

Customer Service and Support

Excellent customer service is non-negotiable. It ensures you receive necessary guidance during the selection process and support throughout the cable's lifespan. Evaluate their pre-sales and after-sales services, including warranties and technical support.

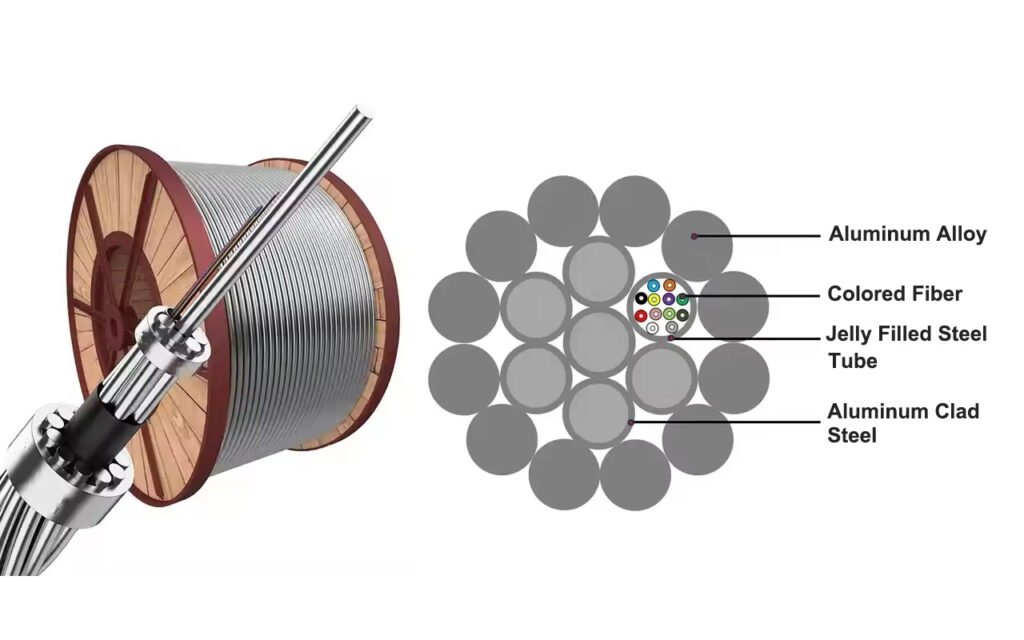

What Material Should the OPGW Cable Be Made Of?

The material composition of an OPGW cable significantly impacts its performance and longevity.

Choose the cable material based on environmental conditions and performance requirements. Common materials include aluminum alloy3, stainless steel, and metal composites, each suited to different needs.

Aluminum Alloy vs. Stainless Steel

Aluminum alloy offers a good balance of strength and conductivity, suitable for various environments. Stainless steel, however, provides superior corrosion resistance, ideal for harsh conditions.

Metal Composite Materials

These materials offer a blend of properties, enhancing the cable’s performance in specific scenarios. Evaluate your environmental conditions to determine the best material choice.

Why is the Type of OPGW Cable Important?

The type of OPGW cable affects its functionality and efficiency in data and power transmission.

Choose between single-mode and multi-mode, and dual-core optical cables based on the number of fibers needed, bandwidth requirements, transmission distance, and signal attenuation.

Single-Mode vs. Multi-Mode

Single-mode4 cables are ideal for long-distance transmissions with minimal signal loss, while multi-mode cables suit shorter distances and higher bandwidth requirements.

Dual-Core Optical Cables

These offer redundancy and enhanced capacity, beneficial in critical applications where uninterrupted service is paramount.

How Do You Evaluate Electrical Parameters?

Electrical parameters determine the cable's ability to operate safely and efficiently in high-voltage environments.

Ensure the OPGW cable can handle high-voltage conditions, focusing on resistance, capacitance, short circuit current rating5, and lightning strike resilience.

Key Electrical Characteristics

- Resistance and Capacitance: Low resistance and capacitance ensure efficient power and data flow.

- Short Circuit Current Rating (SCCR): Essential for safety, ensuring the cable can withstand short circuits without damage.

- Lightning Strike Protection: Critical for outdoor installations, ensuring the cable’s reliability in adverse weather.

What About Mechanical Strength?

OPGW cables must withstand environmental stresses to ensure longevity and performance.

Look for cables with robust armor designs, high tensile strength, and crush resistance to endure mechanical stresses from wind, ice, and other environmental factors.

Armor Design and Material

Robust armor designs, using materials like aluminum or stainless steel, offer protection against physical damage and harsh weather.

Tensile Strength and Flexibility

High tensile strength ensures the cable can handle mechanical loads, while flexibility allows it to adapt to various installation scenarios.

How Do Environmental Conditions Affect Your Choice?

Environmental factors at the installation site significantly influence the cable's performance and durability.

Choose a cable that can withstand temperature variations, humidity, UV exposure, and corrosive elements, ensuring its longevity and reliability.

Weather-Resistant Properties

Ensure the cable is designed to resist weather-related damages, including temperature extremes and UV radiation.

Corrosion-Resistant Features6

For installations in corrosive environments, such as coastal areas, a corrosion-resistant cable material is crucial to prevent degradation.

Is Compatibility with Existing Infrastructure Important?

Ensuring the OPGW cable integrates smoothly with existing systems is vital for operational efficiency.

Confirm the cable’s compatibility with current infrastructure, including fittings, splice closures, and adherence to standards like IEEE, IEC, and ANSI7.

Infrastructure Integration

Compatibility ensures seamless operation and reduces the need for extensive modifications to existing systems.

Adherence to Standards

Compliance with national and international standards guarantees the cable’s quality and reliability across different applications.

How Do Installation and Maintenance Influence Your Decision?

Ease of installation and maintenance affects the overall cost and efficiency of the OPGW cable.

Select cables with user-friendly designs for straightforward installation and maintenance, ensuring easy fiber access for future upgrades or repairs.

Installation Considerations

Cables with suitable outer jackets facilitate easier handling and reduce damage risks during installation.

Maintenance and Upgrades

Ensure the cable design allows for easy access to fibers, enabling efficient maintenance and future technological upgrades.

How Do Price and Performance Balance?

Balancing cost with performance is crucial to making an economically sound decision.

Weigh the budget against performance needs, as higher performance often comes with increased prices. Choose specifications that align with your usage scenarios and financial constraints.

Evaluating Cost vs. Benefit

Consider long-term benefits and performance when evaluating costs, ensuring you’re investing in a cable that meets your needs without overspending.

Scenario-Based Selection

Different scenarios, like urban or rural environments, demand specific cable types. Ensure your choice aligns with the unique demands of your setting.

Why Refer to International Standards?

International standards ensure the cable’s quality and suitability for various applications.

Ensure the OPGW cable meets or exceeds standards

-

Optical Power Ground Wire (OPGW) is a specialized cable that integrates optical fiber with a ground wire, often used in high-voltage power transmission lines for both power and data transmission. ↩

-

When choosing a manufacturer, it's essential to look at their reputation for delivering high-quality, reliable OPGW cables. Manufacturers with proven success in the industry are more likely to provide cables that meet your specifications and standards. ↩

-

Aluminum alloy is commonly used in OPGW cables for its balance of strength, light weight, and good electrical conductivity, making it suitable for various environmental conditions. ↩

-

Single-mode fibers are used for long-distance, low-loss transmission, while multi-mode fibers are better suited for shorter distances and higher bandwidth applications. ↩

-

The Short Circuit Current Rating (SCCR) is crucial in determining a cable's ability to withstand short-circuit conditions without failure, ensuring safe operation in electrical systems. ↩

-

Corrosion-resistant cables are essential in harsh environments where the cable may be exposed to moisture, salts, or chemicals that could degrade the cable's performance over time. ↩

-

Adherence to standards like IEEE, IEC, and ANSI ensures the OPGW cable is compatible with international safety and quality guidelines, guaranteeing reliability across various applications. ↩