How Do Custom OPGW Cable End Fittings Enhance Telecommunications Infrastructure?

In the fast-paced world of telecommunications, ensuring reliable infrastructure is paramount. Yet, one critical detail is often overlooked: the selection of Optical Ground Wire (OPGW) cable end fittings. Custom-designed fittings not only secure the cable mechanically but also enhance electrical grounding and simplify installation. This tailored approach significantly boosts the performance and longevity of OPGW systems.

Custom OPGW cable end fittings improve telecommunications infrastructure by providing solutions designed specifically for high durability, efficient electrical grounding, and easy installation. By using carefully selected materials and configurations, these fittings maximize the reliability and lifespan of OPGW installations.

Imagine a scenario where a network experiences frequent outages due to inadequate cable fittings. By opting for custom OPGW fittings that address specific engineering challenges, telecom engineers can prevent such failures and maintain seamless connectivity. This proactive measure not only solves current issues but also prepares the system for future challenges.

What Factors Influence the Design and Material Selection for Custom OPGW Cable End Fittings?

When designing custom OPGW cable end fittings, material selection is crucial. The fittings typically combine materials such as preformed wire, aluminum alloy, and galvanized steel to achieve high tensile strength, flexibility, and excellent corrosion resistance.

The design and material selection for custom OPGW cable end fittings focus on achieving high tensile strength, flexibility, and resistance to corrosion. Using preformed wire, aluminum alloy, and galvanized steel ensures that the fittings can withstand environmental stresses and extend the cable’s service life.

Preformed wires maintain tension without deforming, aluminum alloys provide a lightweight yet robust structure, and galvanized steel adds durability and protection against rust. These material choices are tailored to meet the specific demands of the installation environment.

Common Materials and Their Uses in OPGW Fittings

| Material | Properties | Application in OPGW Fittings |

|---|---|---|

| Preformed Wire | High tensile strength, maintains shape | Used in dead-end fittings to hold tension |

| Aluminum Alloy | Lightweight, strong, corrosion-resistant | Provides structural support in suspension |

| Galvanized Steel | Durable, rust-resistant | Used in armor rods and clamps for protection |

How Do Structural Components Contribute to the Effectiveness of OPGW Cable End Fittings?

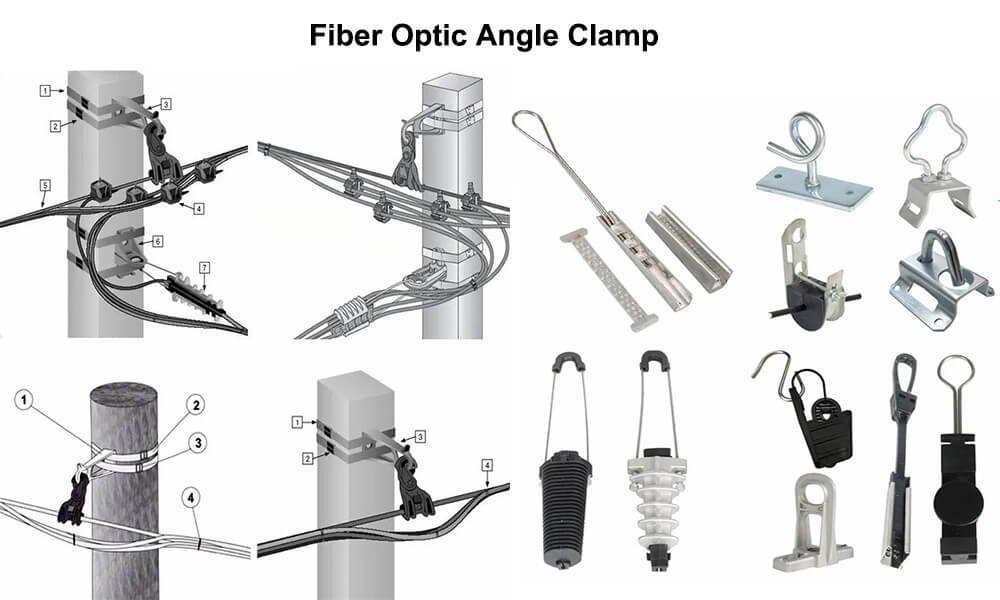

The design of structural components is key to effective OPGW cable end fittings. Components such as clamps, suspension heads, and preformed armor rods work together to secure the cable and distribute stress evenly, protecting the cable from environmental and mechanical damage.

Structural components—like clamps, suspension heads, and preformed armor rods—play a vital role in ensuring that OPGW cable end fittings protect the cable from damage and maintain proper alignment. This not only enhances performance but also extends the system’s operational life.

Each component is engineered to perform a specific function:

- Clamps and Suspension Heads: Wrap around the cable to evenly distribute stress.

- Preformed Armor Rods: Add stiffness and shield the cable from wear.

- Thimble Clevis and Anchor Shackles: Offer flexibility and ensure proper cable bending and positioning.

Key Structural Components in OPGW Fittings

| Component | Function | Benefits |

|---|---|---|

| Clamp & Suspension Head | Distributes stress around the cable | Minimizes damage from environmental factors |

| Preformed Armor Rods | Provides additional stiffness and protection | Enhances durability under mechanical stress |

| Thimble Clevis & Anchor Shackles | Ensure proper bending radius and alignment | Maintains cable integrity during dynamic loads |

Why Are Grounding and Bonding Essential in OPGW Cable End Fittings?

Grounding and bonding are critical for maintaining electrical continuity and overall safety in OPGW systems. Features such as current transfer tabs and grounding wire assemblies ensure that the cable system remains properly grounded, thereby preventing electrical faults.

Effective grounding and bonding techniques are essential in OPGW cable end fittings. They ensure electrical continuity and safety by securely connecting the cable to the supporting structure, using components like current transfer tabs and bonding clamps.

A robust grounding system not only protects against electrical faults but also stabilizes the entire network by dispersing high currents safely.

Grounding and Bonding Features

| Feature | Purpose | Impact |

|---|---|---|

| Current Transfer Tab | Facilitates electrical grounding | Enhances safety by maintaining continuous grounding |

| Grounding Wire Assemblies | Optional components for reinforced grounding | Provides extra protection against electrical surges |

| Bonding Clamps | Secure electrical connections | Ensures consistent and reliable electrical continuity |

What Installation Considerations Are Important for OPGW Cable End Fittings?

Proper installation is crucial to realize the full benefits of custom OPGW cable end fittings. Engineers must ensure that fittings are installed without stress concentrations and that the cable’s sag and tension are maintained according to design specifications.

Key installation considerations include avoiding stress concentrations, ensuring a tool-free and straightforward setup, and maintaining proper sag and tension levels. These practices are vital for the fittings to perform effectively and protect the cable.

Precise installation minimizes damage and ensures that the fittings secure the cable correctly. Careful positioning and marking help maintain the desired cable sag and tension, which are critical for long-term performance.

Installation Considerations for Optimal Performance

| Consideration | Focus | Importance |

|---|---|---|

| Stress Avoidance | Minimizing concentrated stress points | Prevents premature cable failure |

| Ease of Installation | Designing fittings for simple setup | Reduces installation time and risk of errors |

| Sag and Tension | Ensuring correct cable positioning | Maintains operational efficiency and cable longevity |

Conclusion

Custom OPGW cable end fittings are essential for enhancing telecommunications infrastructure. By selecting the right materials, optimizing structural components, ensuring effective grounding, and following best installation practices, these fittings help maintain the integrity and reliability of OPGW systems. Such tailored solutions not only protect the cable system from environmental and mechanical stresses but also ensure long-term performance and safety in modern telecommunications networks.