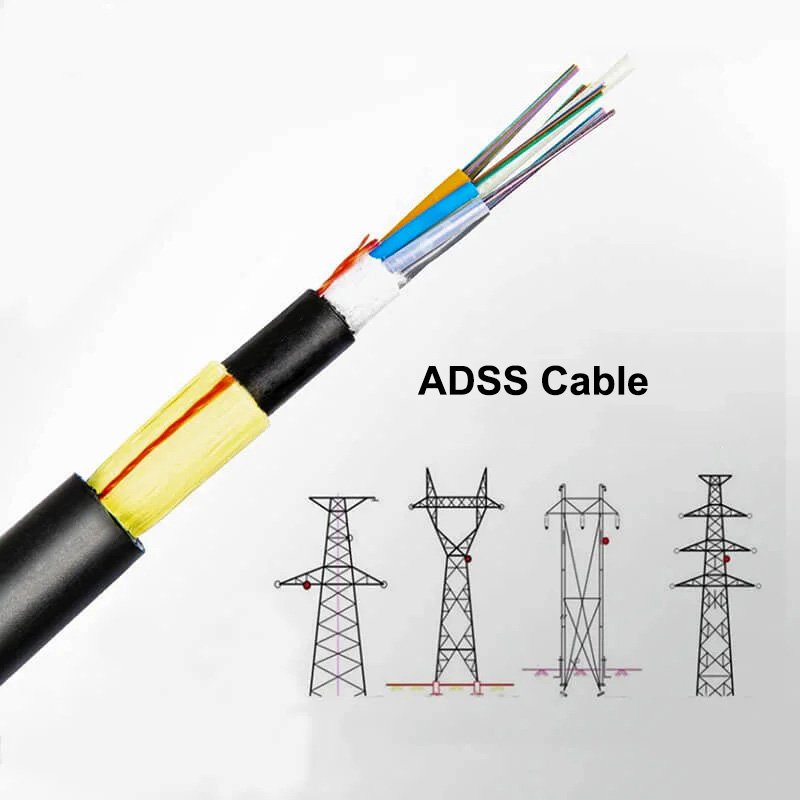

How to Identify High-Quality ADSS Fiber Optic Cables? Understanding Quality Standards and Certifications

Are you struggling to ensure your ADSS fiber optic cables1 meet the highest standards? Without proper certification2 and quality assurance, your installations could face performance issues. Understanding the key certifications and quality standards is essential for reliable and efficient communication infrastructure.

High-quality ADSS fiber optic cables are identified through rigorous certifications and adherence to established quality standards, ensuring they meet international and industry-specific requirements.

Imagine investing in a top-tier ADSS cable only to encounter unexpected failures in the field. This scenario is all too common when quality standards are overlooked. Let’s delve into how certifications and quality benchmarks safeguard your investments and enhance performance.

What Are the Essential Certifications for ADSS Fiber Optic Cables?

Ensuring your ADSS fiber optic cables are certified is crucial for reliability and compliance. Certifications validate that the cables meet specific performance and safety standards required in various applications.

Essential certifications for ADSS fiber optic cables include ISO 90013, UL Certification4, and compliance with IEEE5 standards. These certifications ensure the cables are manufactured under strict quality management systems and have undergone rigorous testing for performance and safety.

When I first started in the fiber optics industry understanding the maze of certifications was daunting. However, recognizing the value each certification brings to the table has been pivotal in selecting the right products for our projects.

ISO 9001 Certification

ISO 9001 is a globally recognized standard for quality management systems. Manufacturers like Futong Group6 obtain this certification to demonstrate their commitment to maintaining high-quality production processes.

| Certification | Purpose | Benefits |

|---|---|---|

| ISO 9001 | Quality Management | Ensures consistent product quality and continuous improvement |

| UL Certification | Safety and Performance | Validates product performance through third-party testing |

| IEEE 1222-2011 | Industry Standards Compliance | Aligns products with electrical utility requirements |

UL Certification

UL Certification involves rigorous testing by third-party laboratories to assess the mechanical strength and environmental durability of ADSS cables. MEFC's UL-certified ADSS cables are a testament to their reliability in harsh conditions.

Testing Parameters

- Mechanical Strength: Ensures cables can withstand physical stresses.

- Environmental Durability: Assesses resistance to UV exposure, moisture, and temperature variations.

IEEE Standards Compliance

Compliance with IEEE 1222-2011ensures that ADSS cables meet the specific testing and performance requirements for use on electric utility power lines. This standard is critical for ensuring the safety and efficiency of aerial installations.

| Standard | Description | Application |

|---|---|---|

| IEEE 1222-2011 | Testing and performance requirements | ADSS cables on electric utility power lines |

| IEEE 802.3 | Ethernet standards | Ensures compatibility with network infrastructure |

| IEEE 1355 | High-speed serial data | Facilitates high-speed data transmission |

How Do Quality Standards Influence ADSS Cable Performance?

Quality standards play a pivotal role in determining the performance and longevity of ADSS fiber optic cables. Adhering to these standards ensures that cables perform optimally under various environmental and operational conditions.

Quality standards influence ADSS cable performance by dictating material specifications, manufacturing processes, and testing protocols, which collectively ensure durability, signal integrity, and reliability in diverse applications.

During a critical data center project, adhering to quality standards prevented potential signal loss and ensured seamless communication across our network infrastructure. This experience underscored the importance of stringent quality adherence.

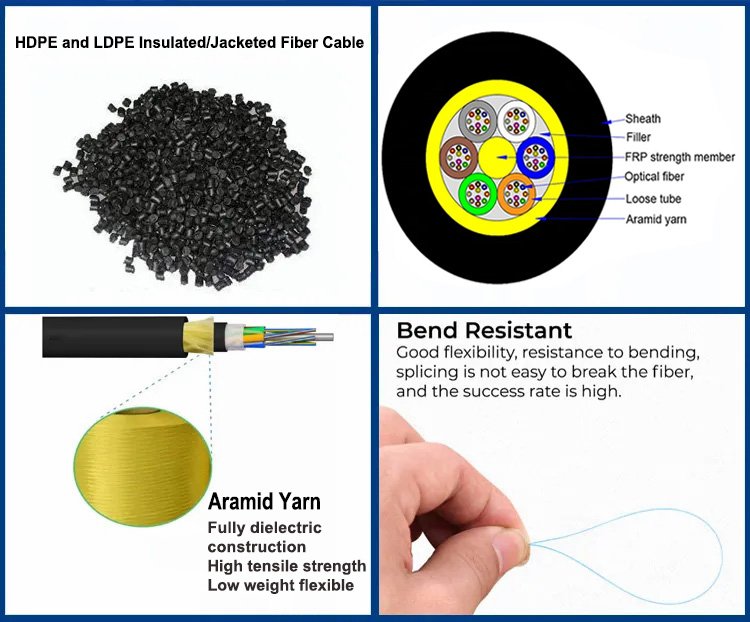

Material Selection

Selecting high-quality materials is fundamental to the durability of ADSS cables. Manufacturers conduct regular inspections to ensure materials meet specified standards, enhancing the cable's resilience against environmental stressors.

Key Material Considerations

- Dielectric Properties: Ensures the cable is non-conductive and safe for aerial installations.

- UV Resistance: Protects the cable from degradation due to sunlight exposure.

- Moisture Barrier: Prevents water ingress, safeguarding the internal fibers.

Testing Protocols

Comprehensive testing throughout the manufacturing process guarantees that each ADSS cable meets performance requirements.

Optical Testing

- Attenuation Rates: Maintaining low attenuation (typically less than 0.4 dB/km) is crucial for preserving signal integrity over long distances.

| Test Type | Purpose | Standard |

|---|---|---|

| Optical Attenuation | Measure signal loss | ITU-T G.6527 |

| Mechanical Tensile | Assess strength | IEEE 1222-2011 |

| Environmental | Test durability | IEC 60793 |

Advanced Manufacturing Techniques

Employing advanced manufacturing technologies enhances production efficiency and ensures each cable meets stringent performance criteria. Techniques such as automated fiber alignment and precision coating application contribute to superior product quality.

Benefits of Advanced Manufacturing

- Consistency: Automated processes reduce variability.

- Efficiency: Streamlined production increases output without compromising quality.

- Innovation: Enables the incorporation of new materials and technologies.

What Should You Look for in an ADSS Fiber Optic Cable Manufacturer?

Choosing the right manufacturer is critical for ensuring you receive high-quality ADSS fiber optic cables that meet your project's specific needs. Factors such as certifications, quality control measures, and customer support play a significant role in this decision.

When selecting an ADSS fiber optic cable manufacturer8, consider their certification credentials, quality assurance processes, customization capabilities, and technical support to ensure they can meet your specific requirements and maintain product reliability.

In my role at ABPTEL, I've found that partnering with manufacturers who prioritize certifications and quality standards significantly enhances project outcomes and client satisfaction.

Certification Credentials

Ensure the manufacturer holds relevant certifications like ISO 9001 and UL Certification. These credentials indicate a commitment to quality management and product reliability.

Certification Table

| Certification | Issuing Body | Significance |

|---|---|---|

| ISO 9001 | International Organization for Standardization9 | Quality management systems |

| UL | Underwriters Laboratories10 | Safety and performance |

| IEEE Compliance | Institute of Electrical and Electronics Engineers | Industry-specific standards |

Quality Assurance Processes

Robust quality assurance processes are essential for maintaining high standards. Look for manufacturers that implement comprehensive testing protocols and continuous improvement practices.

Quality Control Measures

- Incoming Material Inspection: Verifies the quality of raw materials before production.

- In-Process Testing: Monitors quality during manufacturing to detect and address issues promptly.

- Final Product Testing: Ensures the finished cables meet all performance and safety standards.

Customization Capabilities

Manufacturers offering OEM/ODM services11 can tailor products to meet specific project requirements. This flexibility is invaluable for projects with unique specifications or demanding environments.

Customization Options

- Fiber Count: Varying the number of fibers to suit bandwidth requirements.

- Jacket Materials: Selecting appropriate materials for different environmental conditions.

- Connector Types: Providing specific connector configurations for seamless integration.

Technical Support and After-Sales Service

Reliable technical support and after-sales service are crucial for addressing any issues that arise post-purchase. Manufacturers that offer comprehensive support can help ensure the long-term success of your installations.

Support Services

- Installation Guidance: Assists with proper installation techniques to maximize performance.

- Troubleshooting Assistance: Provides solutions for any operational challenges.

- Warranty and Repairs: Ensures product reliability and addresses defects promptly.

Conclusion

Identifying high-quality ADSS fiber optic cables hinges on understanding and verifying the necessary certifications and quality standards. By partnering with certified manufacturers and adhering to stringent quality measures, you can ensure reliable and efficient performance for your communication infrastructure needs.

-

Learn more about ADSS fiber optic cables and their applications. ↩

-

Understand the importance of certifications in fiber optic cables. ↩

-

Discover what ISO 9001 certification entails and its benefits. ↩

-

Find out about UL Certification and its role in ensuring product safety. ↩

-

Learn about the IEEE and its role in setting industry standards. ↩

-

Visit Futong Group's official website for more information about their certifications. ↩

-

Learn about the ITU-T G.652 standard for optical fiber cables. ↩

-

Explore Abptel (China)'s official website to learn more about their products and services. ↩

-

Learn about the International Organization for Standardization and its standards. ↩

-

Find out about Underwriters Laboratories and their role in product safety. ↩

-

Understand the difference between OEM and ODM services in manufacturing. ↩