What Are the Global Trends in ADSS Fiber Optic Cable Supply and Market Dynamics?

Have you ever felt overwhelmed by the multiple ADSS cable suppliers claiming to offer the best technology at the lowest cost? Do you sometimes wonder why ADSS cable pricing varies so drastically, even among reputable manufacturers? I understand those concerns. I have seen how differences in raw materials, manufacturing capabilities, and regional markets create noticeable fluctuations in quality, availability, and price. Let me show you a clearer path through these complexities.

ADSS fiber optic cable supply hinges on manufacturing capacity, material choices, and regional demand. It is best to compare suppliers not just on price but also on the strength of their technical expertise, their ability to maintain consistent quality, and the flexibility they offer in customizing fiber solutions.

I still recall how I once secured a bulk shipment of ADSS cable from a less-known supplier due to their low-cost promise. Several reels turned out inconsistent in their tensile strength, and the jackets began to develop cracks after just a few months in service. That risky choice cost more in replacements than the initial discount ever saved me. My aim here is to help you avoid these pitfalls, whether you are analyzing the global market, looking for a manufacturer in a specific region like India1, or trying to figure out the true cost components of ADSS fiber optic cables.

Why Is the ADSS Fiber Optic Cable Market Growing Globally?

Many telecom and broadband sectors worldwide rely on ADSS (All-Dielectric Self-Supporting)2 fiber optic cables for overhead installations. There is no need for messenger wires, and these cables handle high-voltage environments well. As more regions push toward 5G infrastructure and fiber connectivity, demand continues to surge. This growth is especially notable in emerging markets, where new expansions often involve overhead routes and a need for reliable, cost-effective solutions.

Telecommunication companies see ADSS fiber optic cables as a forward-looking choice. They have excellent dielectric properties, which reduce the risk of electrical interference. They also integrate easily into existing overhead line systems. These advantages drive more procurement managers to focus on ADSS cables for new expansions, especially in areas with challenging topographies or limited underground duct availability. The global market’s upward trajectory reflects this enthusiasm.

In certain regions, government initiatives also spur fiber expansions. A policy may dictate faster broadband coverage, encouraging service providers to look for robust cable solutions that can handle both large data capacity and overhead installation complexities. ADSS cables meet these criteria well, so they become a primary candidate. This dynamic fuels not only demand but also competition among manufacturers.

Looking ahead, continued expansion of data centers, 5G networks, and last-mile connectivity will likely boost ADSS cable demand even more. Larger fiber counts, custom designs, and specialized sheath materials will become vital. Hence, the global ADSS market should keep growing, placing more emphasis on manufacturing quality, supply chain stability, and technological innovation.

Which Regions Lead in ADSS Cable Manufacturing, and Why?

Different parts of the world bring various strengths to the ADSS manufacturing scene. Historically, the United States and certain European nations led fiber optic research, but Asian countries, especially China3, have emerged as heavyweights in terms of production capacity and cost competitiveness. India1 has also risen steadily, establishing itself as a significant supplier to local and international telecom projects.

North America

North America has advanced R&D capabilities. Some well-known brands offer high-end cables with proprietary technology. However, the cost of labor and materials can be higher. Buyers looking for specialized solutions or top-tier brand recognition often turn to North American manufacturers.

Europe

Europe’s fiber optic cable manufacturers emphasize stringent quality control and compliance with environmental standards. Many European cable vendors produce cables meeting advanced certifications, especially for harsh climates. However, Europe’s higher labor costs also reflect in cable pricing.

China

China is a major hub for ADSS cable production. Extensive manufacturing infrastructure, cost-effective labor, and large-scale operations help Chinese manufacturers offer competitive pricing and faster turnaround times for bulk orders. Many now invest in R&D labs that ensure cables meet global standards. However, the Chinese market can be very broad, so verifying certifications is crucial.

India

India’s manufacturing ecosystem for fiber optic cables has been expanding. Government incentives and local telecom expansions push companies to ramp up production capacity. Indian manufacturers can be competitive in price, but thorough technical checks remain essential.

Other Emerging Players

Countries in Southeast Asia, Latin America, and the Middle East also see interest in local ADSS cable production. They may rely on joint ventures or licensing. As demand grows in these regions, local production can reduce import costs and lead times.

How to Choose a Reliable ADSS Fiber Optic Cable Manufacturer?

Choosing a manufacturer can be daunting. Not all manufacturers are equal in materials consistency, testing protocols, and after-sales support. Here are some guidelines:

- Technical Expertise: Look for advanced fiber knowledge, R&D facilities, and proven engineering support.

- Production Capacity: Balance large-scale output with quality control.

- Testing Capabilities: Confirm they meet IEC or ITU standards4, run pre-shipment inspections, and can share real batch data.

- Material Sources: High-grade fiber (e.g., Corning), reliable reinforcement yarn (like aramid yarn5), and consistent sheath compounds.

- OEM/ODM Services: If you need custom design, see if they offer an OEM/ODM approach6.

- Reputation & After-Sales: Check references, warranty terms, and local support availability.

- Geographic Factors: Shipping costs, tariffs, and lead times might favor a regional supplier.

What Are the Key Factors Affecting ADSS Cable Cost and Pricing?

Price differences often stem from raw fiber quality, reinforcement materials, specialized jackets, labor costs, and testing rigor. Here are some highlights:

- Fiber Grade: Premium fibers cost more but offer better attenuation specs.

- Reinforcement Material: Aramid yarn vs. glass yarn can impact strength and price.

- Sheath Compounds: High-voltage environments may require anti-tracking jackets, increasing cost.

- Fiber Count: More fibers = larger diameter, more materials, higher cost.

- Regional Overheads: Labor costs, shipping, and tariffs vary by manufacturer location.

- Batch Size & Lead Time: Volume discounts vs. rush orders.

- Testing & Certifications: Thorough testing adds to cost but prevents field failures.

How Do Material Choices Influence Performance and Price?

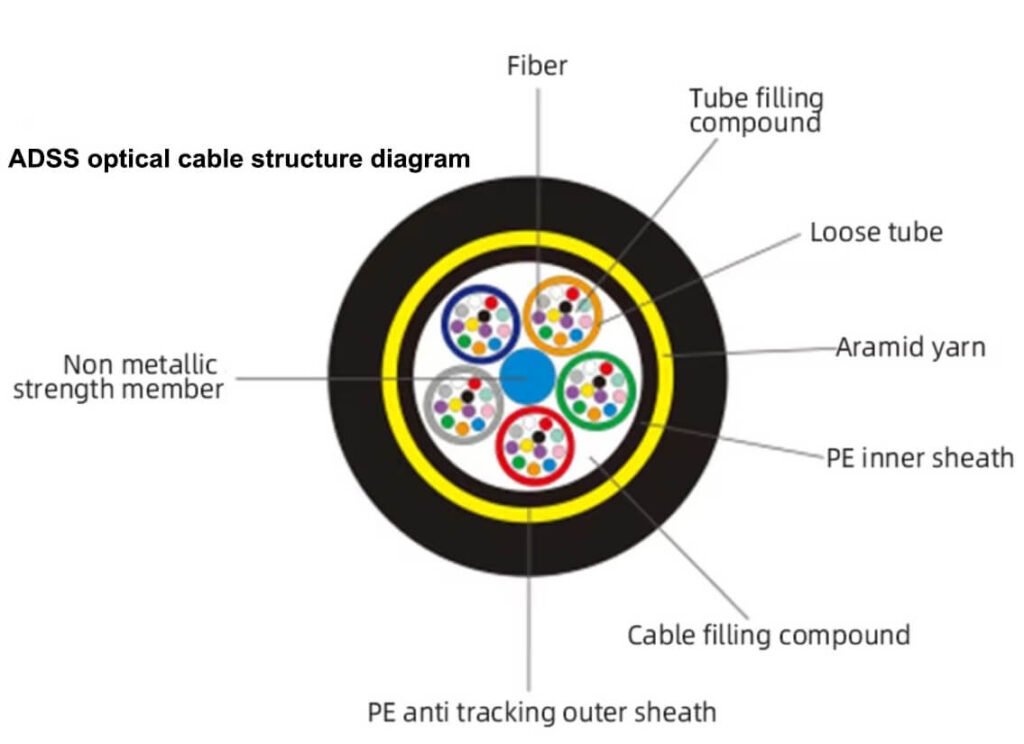

Every layer in an ADSS cable—core fiber, reinforcement, sheath—affects durability and cost. For instance:

- Fiber Type: Standard G652D vs. bend-insensitive G657.

- Reinforcement: Aramid yarn provides high tensile strength; glass yarn might be cheaper but with different elongation.

- Jacket Compounds: Basic PE vs. anti-tracking.

- Water Blocking: Gel vs. dry yarn or tape.

- Armor or Rodent Protection: Extra layers increase weight and cost but can save on maintenance in rodent-heavy areas.

When Should You Negotiate Prices or Look for Alternatives?

- Benchmark Quotes: Align specs (fiber type, reinforcement, jacket) before comparing prices.

- Total Cost of Ownership: Cheaper cables may fail sooner, leading to costly replacements.

- Volume Commitments: Large orders can secure better rates.

- Timing & Market Cycles: Raw material price fluctuations and supply-demand shifts can create negotiation windows.

- Risk Assessment: Test a small pilot order with a new supplier before awarding large contracts.

How Do You Compare Global Suppliers for Long-Term Success?

- Technical Criteria: Match your specs (fiber brand, jacket type) to each supplier’s expertise.

- Quality Systems: Look for ISO certifications and robust material traceability.

- Sustainability & Compliance: Eco-friendly processes and social responsibility.

- Innovation & R&D: Seek suppliers who keep pace with new cable designs for 5G or high-voltage lines.

- Global Logistics: Warehouses or distribution centers for faster delivery.

- Reputation & References: Customer reviews, case studies, and local operator endorsements.

- Long-Term Partnership: OEM/ODM flexibility, training, warranties, and on-site support.

Conclusion

Global demand for ADSS fiber optic cables keeps rising due to new telecom builds, 5G rollouts, and robust overhead requirements. Yet, not all suppliers share the same standards or cost structures. Evaluating raw materials, manufacturing capacity, testing protocols, and customer support is key to finding a dependable partner.

Balancing performance needs with budget constraints requires careful attention to fiber type, reinforcement, jacket materials, and testing. Negotiating, understanding batch sizes, and building strong supplier relationships can lead to favorable pricing and reliable deliveries.

By comparing worldwide manufacturers on technical proficiency, quality systems, logistics, and forward-thinking R&D, you ensure your ADSS deployments meet long-term performance goals while justifying total ownership costs.

-

This resource explains India’s growing role in ADSS cable production. By clicking it, you see how government initiatives and local demand fuel a competitive telecom industry. ↩ ↩

-

This resource clarifies what ADSS fiber optic cable is, how it’s constructed, and why it’s chosen for overhead networks. By clicking it, you gain foundational knowledge of ADSS cables. ↩

-

This resource discusses China’s large-scale ADSS cable manufacturing capabilities. By clicking it, you’ll learn how China became a key supplier with high-volume, cost-effective output. ↩

-

This resource outlines global standards like IEC, ITU. Clicking it helps you ensure the ADSS cable you choose meets recognized benchmarks for performance and safety. ↩

-

This resource compares aramid vs. glass yarn. Clicking it clarifies performance, cost, and durability differences in tensile reinforcements for ADSS cables. ↩

-

This resource shows how OEM/ODM approaches allow custom ADSS cable design. By clicking, you understand how tailored specs or branding benefit large-scale fiber deployments. ↩