ADSS Fiber Optic Cable Solutions for Reliable Aerial Network Deployments

ADSS Cable

Abptel, as a leading manufacturer of ADSS cables, specializes in providing high-quality, all-dielectric, self-supporting cables for various industrial and commercial applications. Our ADSS cables, produced in our state-of-the-art factory in China, adhere to strict environmental and IEC operational standards, ensuring optimal performance and longevity.

ADSS (All Dielectric Self-Supporting) cable is a type of fiber optic cable designed for aerial applications, where it is strong enough to support itself between utility poles or other structures without requiring additional metallic support. It contains no conductive metal elements, making it suitable for installation alongside high-voltage power lines without the risk of electrical interference.

ADSS cables can accommodate both single-mode (G.652/G655) and multi-mode fibers, with capacities ranging up to 144 fibers. They are primarily used in outdoor environments, such as aerial installations, and are ideal for applications ranging from local network loops to town-to-town communications. The comprehensive cabling system includes not only the fiber optic cables but also the suspension hardware, dead-end components, and termination enclosures, providing a reliable and robust transmission infrastructure.

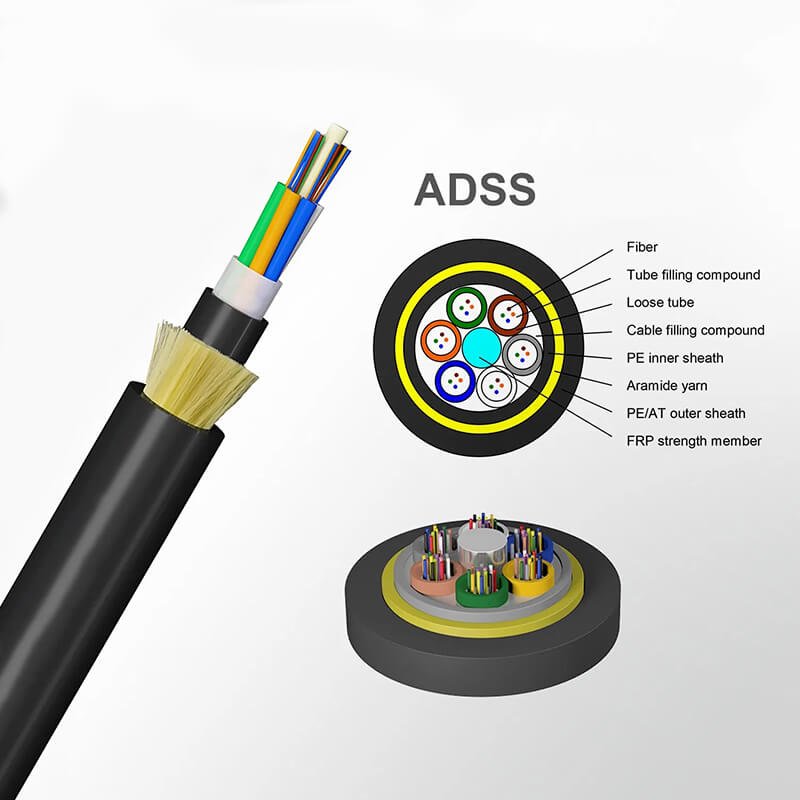

Simplified Cross-Section of a Fiber Optic Cable

A fiber optic cable cross-section with outer layers and internal fibers exposed

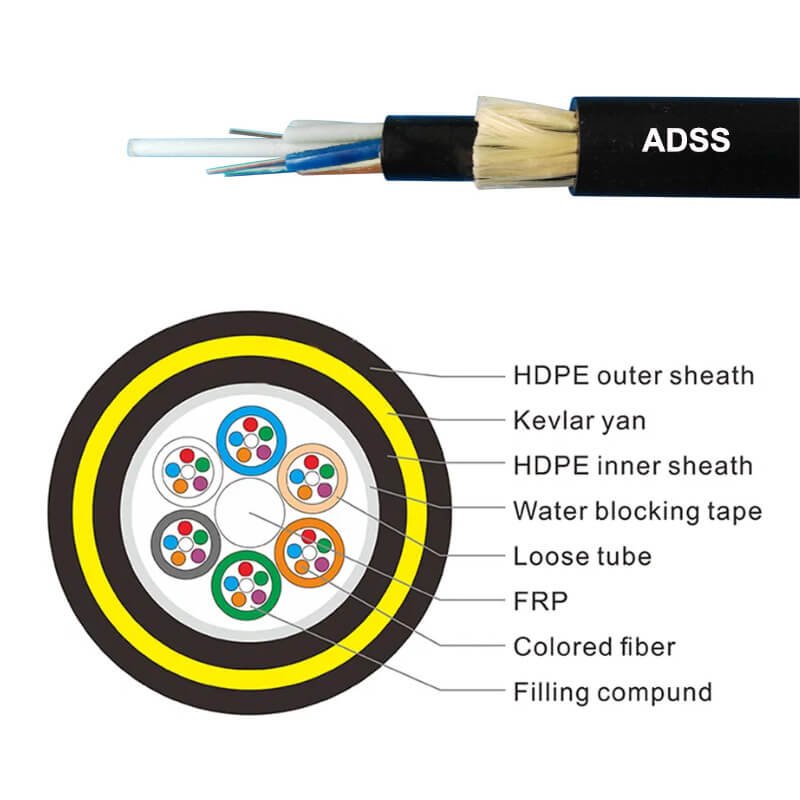

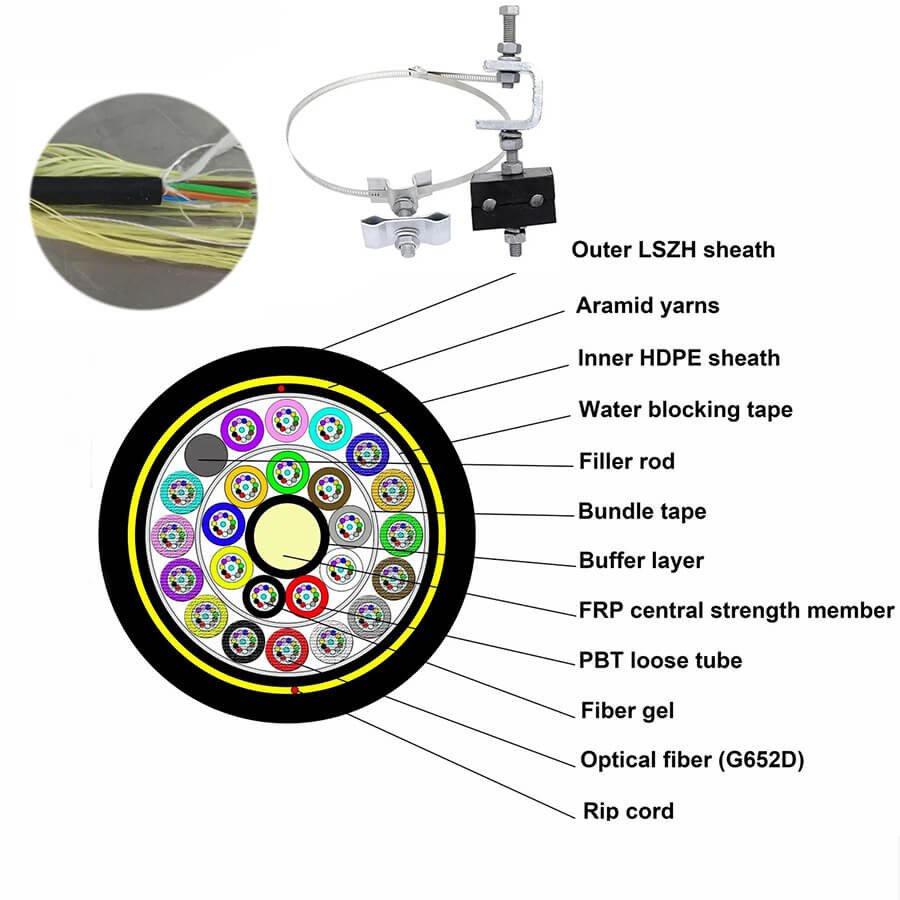

Cross-Section of an ADSS Fiber Optic Cable

A detailed cross-section of an ADSS fiber optic cable revealing internal layers

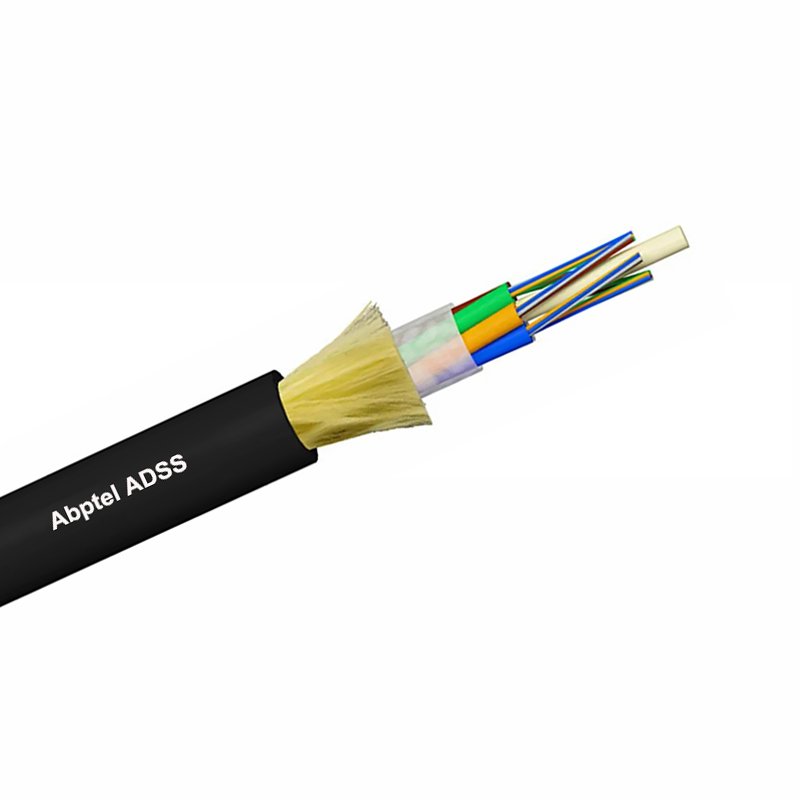

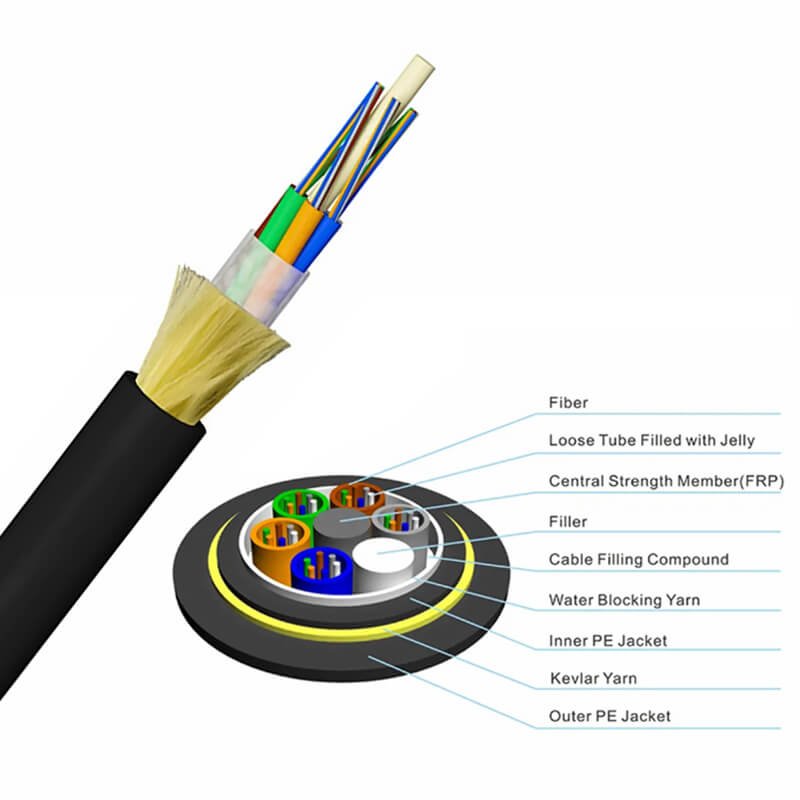

ADSS fiber optic cable with internal layers exposed

Cross-section of ADSS fiber optic cable with internal layers exposed

ADSS Optical Fiber Cable 220KV Anti-Tracking Cable

220KV Anti-Tracking ADSS Cable and line tower sketches

ADSS Fiber Optic Cable with Cable Reel

A spool of ADSS fiber optic cable with a detailed cable cross-section

ADSS Fiber Optical Optic Cables Outdoor Supporting

96 core adss fiber optical optic cables outdoor self supporting

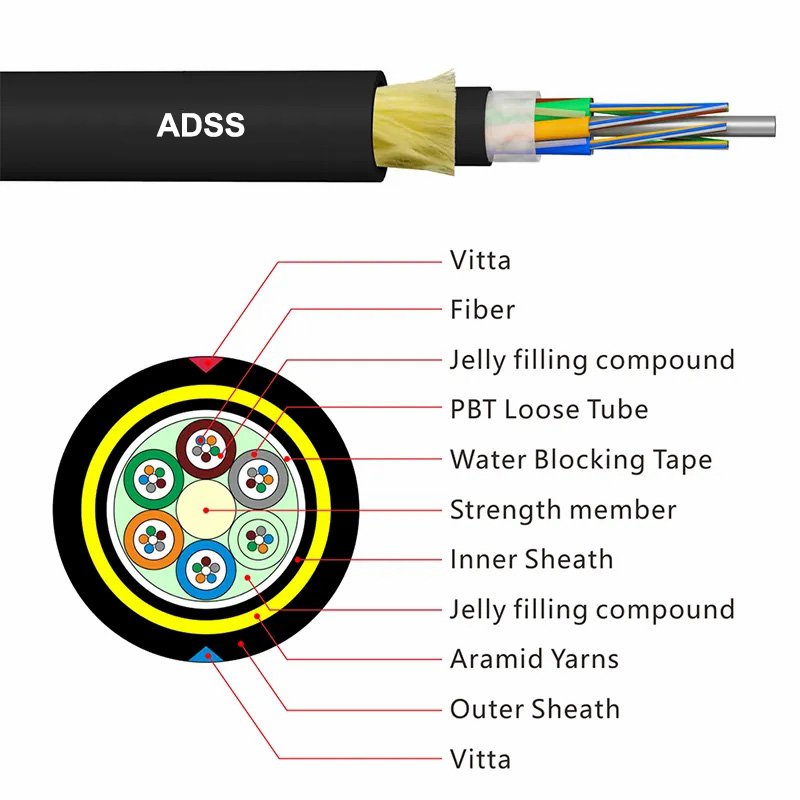

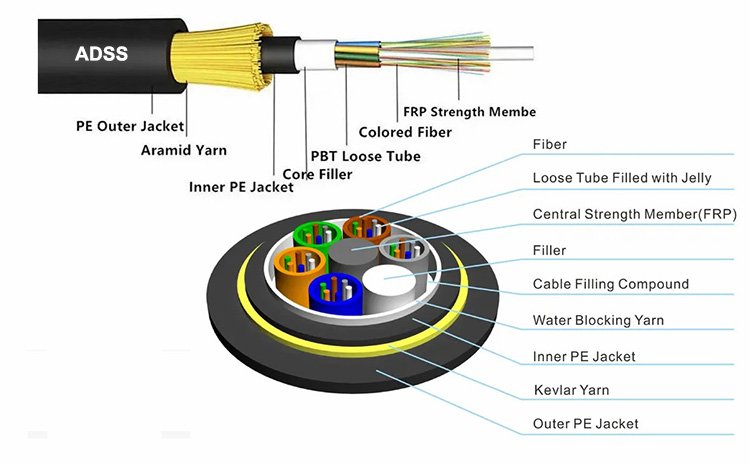

Labeled Diagram of an ADSS Fiber Optic Cable

A detailed labeled diagram showing the components of an ADSS fiber optic cable

Self-Supporting ADSS Largest Span Fiber Optic Cable

2 to 288 Core G652D Self-Supporting ADSS largest span Fiber Optic Cable

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About ADSS Cables

Our ADSS cables use single-mode fibers (SMF) that comply with international standards such as G.652 and G.655 (custom options available based on requirements).

- G.652 Fiber: Standard single-mode fiber, ideal for general communication with low attenuation.

- G.655 Fiber: Zero dispersion fiber, suitable for long-distance, high-bandwidth applications, and minimizing dispersion effects for high-speed networks.

Fiber Count:

Abptel offer ADSS cables with 6 to 288 fibers per cable, depending on your needs. Common configurations include: 6, 12, 24, 48, 96, and 144 fibers.

The fiber count will impact the cable’s overall diameter and structure. You can select based on your network capacity and future expansion requirements.

Jacket:

Typically, our ADSS cables include single sheath or double jacket to allow for long distance tensile requirements. Custom configurations can be requested.

Fiber Performance

Fiber Type | Attenuation | Bandwidth | Chromatic Dispersion |

|---|---|---|---|

| G.652 Fiber | – 0.35 dB/km at 1310 nm – 0.22 dB/km at 1550 nm | – 50 MHz·km (100 MHz·km @ 1310 nm) | – 17 ps/nm·km (standard applications) |

| G.655 Fiber | – 0.33 dB/km at 1310 nm – 0.19 dB/km at 1550 nm | – 70 MHz·km (designed for high-speed, long-distance transmission) | – Negative dispersion (ideal for long-distance and high-bandwidth networks) |

Explanation:

- Attenuation: Low signal loss over long distances, suitable for applications exceeding 100 km.

- Bandwidth:

- G.652: Suitable for general transmission.

- G.655: Supports high-speed, long-distance data transmission (ideal for 100G+ networks).

- Chromatic Dispersion:

- G.652: Standard dispersion for general use.

- G.655: Negative dispersion, optimized for long-distance and high-bandwidth applications.

ADSS Cable Structure and Materials

Our ADSS cables are designed with a loose tube structure and reinforced material for enhanced mechanical protection.

Fiber Structure:

- Fiber Layer: Fibers are arranged within one or more buffered tubes, with each fiber individually protected.

- Strength Member: Uses Kevlar Aramid Yarn or Glass Yarn to provide the necessary tensile strength for the cable.

- Sheath Layer: The outer sheath can be made from Polyethylene (PE) or AT Sheath material, depending on your environmental requirements.

Outer Sheath Material:

The outer sheath is designed to resist UV radiation and corrosion, ensuring long-term performance in outdoor environments.

PE (HDPE/MDPE): Ideal for outdoor use, providing excellent UV resistance and anti-corrosion properties.

AT Sheath (Anti-Tracking Sheath):Designed for environments with high voltage exposure, the Anti-Tracking (AT) sheath is specifically formulated to prevent tracking and surface degradation caused by electrical discharges. This advanced sheath material offers:

- High Voltage Resistance: Effectively withstands electric fields in high voltage transmission environments.

- Anti-Tracking Properties: Prevents surface erosion and degradation under high-voltage and wet conditions.

- Durability in Harsh Environments: Provides long-term protection in polluted or high-humidity areas.

- Enhanced Insulation: Ensures safety and reliability for optical cables used in critical applications.

Ideal for use in 110kV and above power line installations or regions with severe environmental pollution.

Mechanical Performance

Tensile Strength:

Our ADSS cables are designed to withstand a tensile strength of 1000 N to 7000 N, depending on the fiber count and reinforcement design.

Standard Tensile Strength: For example, ADSS cables with 48 fibers typically withstand 2000 N, suitable for general aerial installation.

High Tensile Strength: For specialized installations in extreme environments, tensile strength can reach up to 4000 N.

Crush Resistance:

Our cables can endure a crush resistance of 3000 N/100mm, ensuring the fibers remain intact even when subjected to external pressure, such as during construction or installation.

Minimum Bend Radius:

The minimum bend radius of our ADSS cables is typically 10 times the outer diameter of the cable. For example, if the cable diameter is 10mm, the minimum bend radius is 100mm.

We also offer bend-insensitive designs that reduce the minimum bend radius to 6 times the outer diameter for applications with tighter installation requirements.

Impact Resistance:

Our ADSS cables are designed to withstand shock and impact tests, ensuring they remain stable and functional even in seismic or rough handling conditions during installation.

Considerations When Buying ADSS Cables

When purchasing ADSS (All Dielectric Self-Supporting) fiber optic cables, several key factors should be taken into account to ensure that the product meets your specific requirements. Here, we outline the essential considerations for selecting the right ADSS cables that suit your project needs:

Environmental Compatibility

Outdoor Durability:

ADSS cables are designed to withstand harsh outdoor conditions. It is essential to consider factors like UV exposure, temperature fluctuations, humidity, corrosion, and mechanical stress. Our ADSS cables feature UV-resistant polyethylene (PE) or AT sheaths, ensuring longevity and reliable performance in highly demanding outdoor environments.

High Voltage & Lightning Protection:

For installations near high-voltage power lines, ADSS cables with an AT (Aluminum Tape) sheath offer electrical protection and electromagnetic shielding, safeguarding the fibers from electrical surges, lightning strikes, and electrostatic discharge. This added layer of protection is essential for areas with high electrical interference.

Temperature Range:

Our cables are built to operate within a wide temperature range, typically from -40°C to +70°C, ensuring that they perform reliably in both tropical heat and colder climates.

Compliance and Standards:

Global Compliance:

Our ADSS cables are manufactured in strict adherence to international standards such as ITU-T G.652, G.655, IEC 60794, and RoHS regulations. This guarantees that the fibers are optimized for performance, and the cables are safe and environmentally friendly.

Industry Certifications:

We ensure that all our cables meet ISO 9001 for quality management, ISO 14001 for environmental management, and OHSAS 18001 for occupational health and safety. Additionally, our cables are tested and certified for corrosion resistance.

Application and Scope of Use

- Telecommunications Networks:suitable for installation in aerial settings, typically between utility poles or along power lines.

- Power Line Communication:

for power utilities and electricity grid networks

ADSS Cable Quality Control and Testing

Attenuation and Bandwidth Performance (measuring signal loss over distance)

Tensile Strength (ensuring the cable withstands required load and stress)

Crush and Impact Resistance (to verify physical protection under pressure)

Temperature and Environmental Resistance (to confirm performance in extreme conditions)

Certifications and Inspection:

Our cables are tested in accordance with international standards (such as IEC, ISO, and TIA/EIA). Detailed test reports are available upon request to ensure compliance with your specific project requirements.

Other Questions When Buying ADSS Cables

Why Choose ADSS Cables?

Self-Supporting:

Ease of Installation:

Cost-Effective:

Comparing ADSS with OPGW

Advantages of ADSS Cables:

Advantages of OPGW Cables:

CONTACT US

Need any urgent help? to hire us now!

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Call For Booking

+86 18814455697

Have A Questions ?

Candy@abptel.com

Location Address

5/F, Building 10, Tangwei Cuihai Industrial Zone, Fuyong Town, Baoan District, Shenzhen