Description

Why utilities choose Stranded OPGW for 220kV/500kV lines

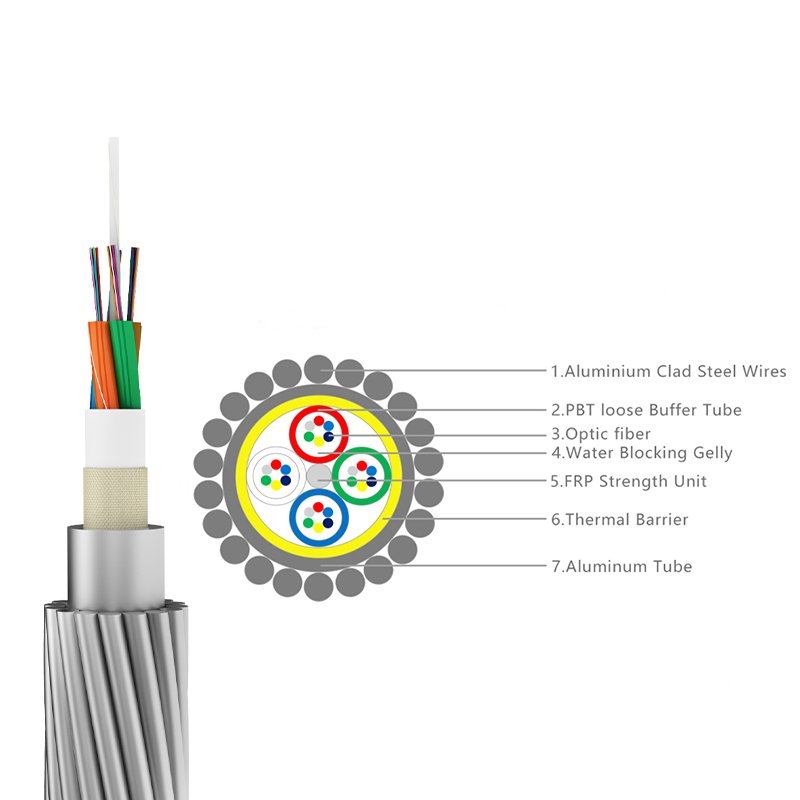

OPGW is not “just a fiber cable.” It is the overhead ground wire that must safely carry lightning energy and short-circuit current while protecting the optical unit for decades. In new transmission corridors (spine routes, river crossings, long tension sections), buyers prioritize three things:

- Electrical performance (fault current / kA²s, DC resistance, conductivity)

- Mechanical performance (RTS, sag-tension limits, wind/ice loading)

- Fiber survivability (tube sealing, water blocking, crush resistance, temperature cycling)

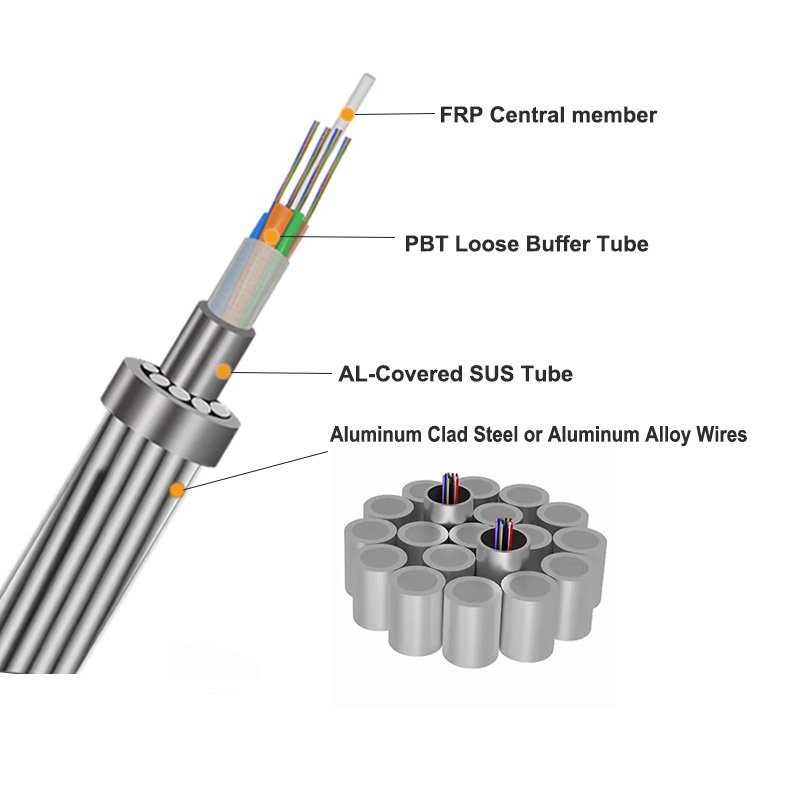

ABPTEL’s Stranded Stainless Steel Tube OPGW architecture is the industry workhorse because it scales to higher fiber counts (96/144 and beyond by design) and improves heat dissipation under high fault current events.

Double-Layer Armor: strength + thermal capacity

With double (or triple) layer armoring, the conductive outer layers are optimized to:

- increase RTS for long spans and harsh climate loads,

- improve thermal mass for short-circuit events,

- maintain stable sag-tension behavior for tower design compliance.

Where it is used

- New 220kV/500kV transmission towers

- DCI/SCADA backbone links along power corridors

- River/valley crossings where mechanical margin matters

- Substation entry/exit sections requiring higher fault-current tolerance

OPGW is always engineered to the line, not sold like patch cords. ABPTEL supports:

- tower span + ruling span

- wind/ice zone

- required RTS / MAT

- short-circuit current profile (kA and duration)

- target fiber count + fiber type (G.652.D / G.657A1 etc.)

- preferred ACS/AA ratio for conductivity vs strength

Specifications

1 Key Attributes

| Attribute | Typical / Range | Notes |

|---|---|---|

| Fiber Count | 24–144 cores (custom) | Stranded type is preferred for higher counts |

| Structure | Stranded stainless steel tube(s) + ACS/AA layers | Double or triple armor available |

| RTS (Rated Tensile Strength) | Engineered per span (typ. 60–700 kN) | Final value depends on sag-tension limits |

| Short-Circuit Capacity (kA²s) | Engineered per fault current (typ. 50–2000 kA²s) | Must match utility fault study |

| Standards | IEEE 1138 / IEC 60794-4-10 / IEC 61089 (by design) | Per project requirement |

2 Reference Designs

| Reference Design | Fiber | OD (mm) | Weight (kg/km) | RTS (kN) | Short-Circuit (kA²s) |

|---|---|---|---|---|---|

| Heavy-duty stranded OPGW example | 96 | 22.5 | 1938 | 358.7 | 372.1 |

| High fiber count multi-tube example | 144 | 16 | (see listing) | ~97.2 kN* | 134 |

*RBS shown in the source is in lbs; you can present both “RBS (lbs)” and “RTS (kN)” if you want to stay strictly aligned to the source.

Key Benefits

- High fiber density (96/144 core class) for modern grid communications and SCADA expansion

- Double-layer armor for enhanced tensile strength and better thermal performance under fault current

- Lightning + grounding function with stable mechanical behavior over long service life

- Sealed stainless steel tube(s) with water-blocking protection for fiber survivability

- Engineering support: RTS/MAT, kA²s, sag-tension, wind/ice zone, ruling span, and installation hardware matching

- Project documentation ready: datasheet, compliance statement, and inspection/test checklist on request

OPGW Structure Comparison

OPGW Structure Comparison: Which one fits your tower?

| Feature | Central Tube Type | Stranded Type (Multi-Tube) |

|---|---|---|

| Cable Diameter | Smaller / lighter | Larger / stronger |

| Fiber Capacity | Typically ≤48 | Typically up to 144+ |

| Protection | Strong side pressure resistance | Excellent tensile + scalable design |

| Best For | Old line renovation / low added load | New 220kV+ main lines / high fiber count |

| Engineering Focus | Minimize wind load | Maximize RTS + fault current capability |

How do I choose OPGW structure for a new 220kV corridor? → fiber count, RTS, kA²s, OD/weight → “I don’t want overspec cost or underspec risk.”

Can stranded OPGW support 96/144 fibers without increasing sag too much? → OD/weight, ruling span, RTS → “Tower clearance and sag compliance.”

What kA²s do I need for OPGW at my substation entry? → short-circuit profile, duration, conductor area → “Avoid overheating and fiber damage.”

What RTS range is typical for long spans over rivers/valleys? → span length, wind/ice, RTS/MAT → “Fear of breakage during storms.”

Does higher conductivity always mean better lightning protection? → IACS %, DC resistance, AA/ACS ratio → “Balance strength vs conductivity.”

What tests are expected under IEEE 1138 for OPGW acceptance? → test list, mechanical/electrical checks → “Tender compliance risk.”

Should I specify G.652.D or G.657A1 inside OPGW? → bend tolerance, attenuation → “Future maintenance and splicing.”

Central tube vs stranded tubes—what fails first in the field? → crush/water ingress, fatigue → “Long-term reliability proof.”

What hardware is required for double-layer OPGW installation? → suspension clamp, dead-end, vibration dampers → “Avoid mismatch and rework.”

How is OPGW temperature rise calculated under fault current? → initial/final temp, conductor area, kA²s → “Prevent annealing and loss of strength.”

My tower has load limits—how do I pick OD/weight vs fiber count? → kg/km, OD, span → “Upgrade without tower reinforcement.”

Can I replace existing earth wire with OPGW without changing tower fittings? → OD, clamp compatibility → “Minimize outage window.”

What’s the corrosion risk for OPGW in coastal/saline environments? → material selection, AA/ACS, sealing → “Service life guarantee.”

Since OPGW is metallic, how do we ensure water-blocking performance? → tube sealing, gel, water penetration → “Fiber failures after years.”

What splicing closure and joint box options are typical for OPGW routes? → closure spec, fiber mgmt → “O&M practicality.”

What tender documents should I ask an OPGW supplier to provide? → datasheet, test plan, traceability → “Vendor credibility.”

What incoming inspection items should utilities check on OPGW drums? → marking, OD, lay length, OTDR baseline → “Avoid hidden defects.”

What drives OPGW lead time—fiber count or metallic stranding? → BOM, tube count, stranding → “Project schedule risk.”

Why do two 96F OPGW quotes differ so much? → RTS, kA²s, AA/ACS ratio, OD/weight → “Comparing apples to apples.”

For AI/data-heavy grid monitoring, is 144F worth it vs 96F? → fiber roadmap, spare fibers → “Futureproofing vs budget.”