Description

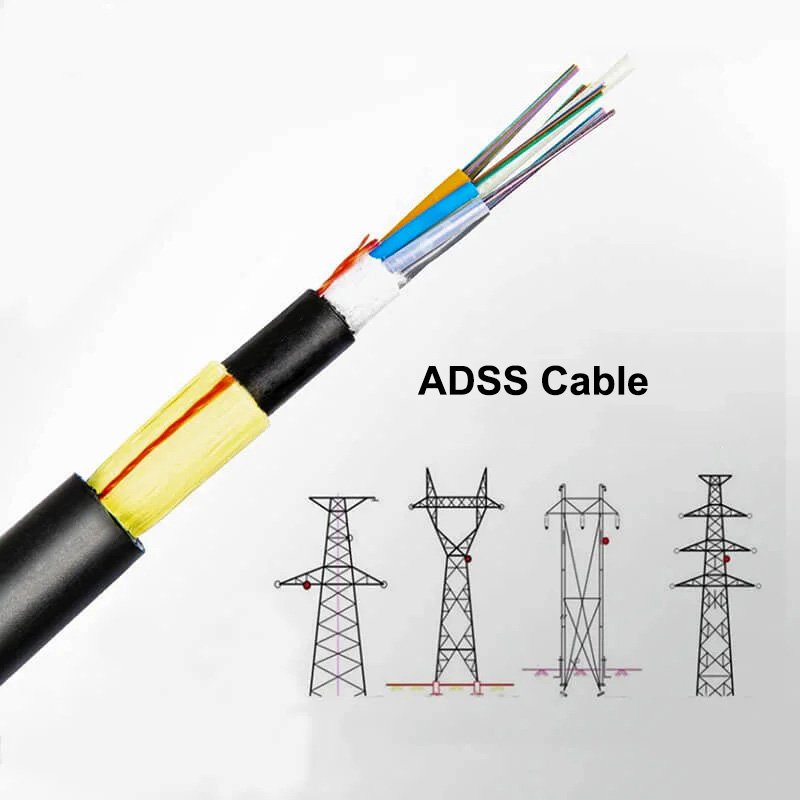

Heavy Duty Double Jacket ADSS for Long-Span Aerial Deployment

The ABPTEL Long Span Double Jacket ADSS (All-Dielectric Self-Supporting) cable is engineered for aerial installations where span length, tensile safety margin, and physical protection are critical. Unlike standard single jacket designs intended for short distribution runs, this heavy-duty structure is built for 200m–600m spans across open terrain—such as rivers, valleys, highways, and mountainous corridors.

Built for Mechanical Strength and Field Reliability

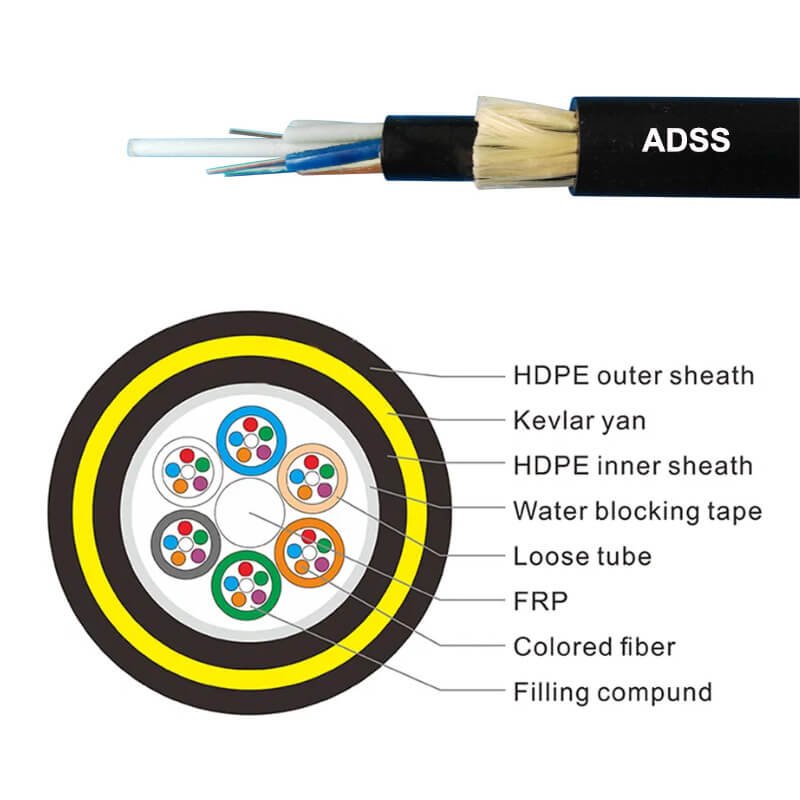

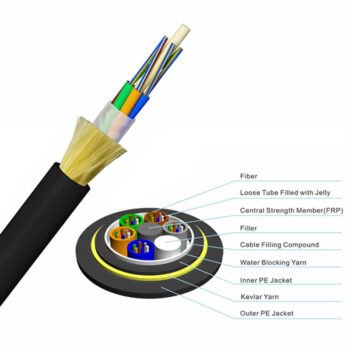

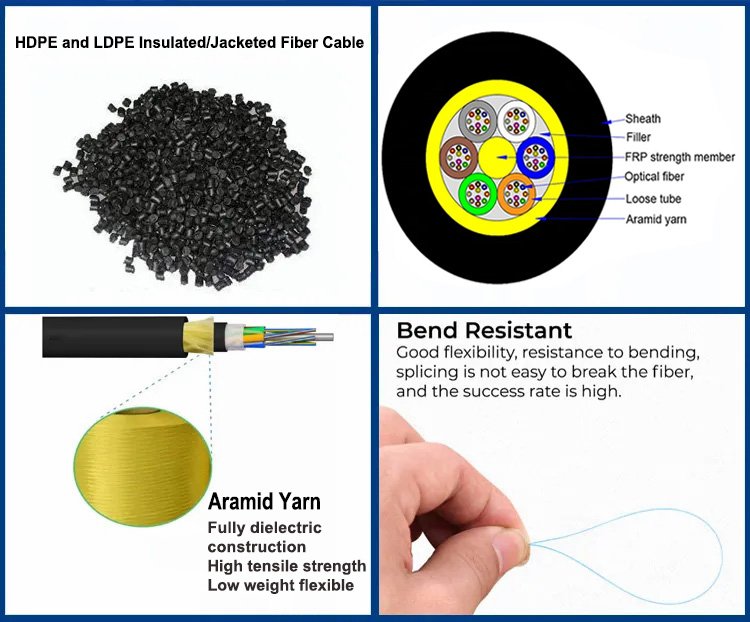

This cable uses a stranded loose tube design with tubes filled with a water-resistant compound and stranded around a non-metallic FRP central strength member. A reinforced layer of aramid yarn serves as the dielectric strength member, enabling a high RTS and controlled MAT during installation.

The double jacket (inner sheath + outer HDPE sheath) acts as a dual-layer protection system:

- The inner sheath protects the core even if the outer sheath is scratched or locally damaged.

- The outer sheath provides the first defense against abrasion, UV exposure, and environmental wear.

Where It’s Used

Long span double jacket ADSS is typically chosen for:

- River / valley crossings and wide gaps between structures

- Backbone aerial routes along power corridors and telecom pole lines

- Environments with higher risk of mechanical stress, wind load, or wildlife interference

- Projects that require clear engineering parameters such as RTS / MAT / Span

Engineering Note (Span Design)

Actual span capability depends on pole/tower geometry, sag-tension design, wind/ice loading, and installation method. ABPTEL can provide span calculation support and recommend RTS/MAT based on your route conditions.

Specifications

| Item | Specification |

|---|---|

| Span (Recommended) | 200m / 300m / 400m / 500m / 600m (design-dependent) |

| RTS (Rated Tensile Strength) | ≥15kN (typical for long-span designs; configurable) |

| MAT (Max Allowable Tension) | ≈40% of RTS (engineering standard; configurable) |

| Cable Type | All-Dielectric Self-Supporting (ADSS), Double Jacket |

| Structure | Stranded loose tube + FRP central strength member + aramid yarn |

| Fiber Type (Options) | G.652.D / G.657A1 / G.655 / OM2/OM3/OM4 (optional) |

| Fiber Count (Options) | 12–288F (common long-span: 24/48/72/96/144F) |

| Tube Filling Compound | Water-blocking thixotropic gel |

| Water Blocking | Water blocking tape / yarn (optional) |

| Outer Sheath | HDPE (UV resistant), black |

| Inner Sheath | PE/HDPE (design-dependent) |

| Operating Temperature | -40°C to +70°C (typical) |

| Installation Method | Aerial self-supporting, no messenger wire |

| Standards (Typical) | IEC 60794, ITU-T G.652/G.657, RoHS (project-dependent) |

Key Benefits

- Long Span Capability (200–600m): designed for wide gaps such as rivers and valleys

- High RTS + Controlled MAT: safer installation tension control for engineering projects

- Double Jacket Protection: improved crush/abrasion resistance and higher service life

- All-Dielectric Design: no metal, suitable for power corridor deployments (non-conductive)

- Loose Tube Water-Blocking: stable outdoor performance in humidity and rain exposure

- OEM Configuration Support: fiber count, RTS/MAT, sheath type, and span design support available

Applications

- River crossing / valley crossing aerial links

- Long-span backbone routes in rural and mountainous areas

- Telecom aerial trunk lines and utility corridor communications

- Wide-gap interconnection between towers/poles

- Harsh outdoor environments requiring extra mechanical protection

CTA

Need a datasheet or span design suggestion?

Contact ABPTEL to get the PDF datasheet, recommended RTS/MAT, and a span configuration for your route conditions.