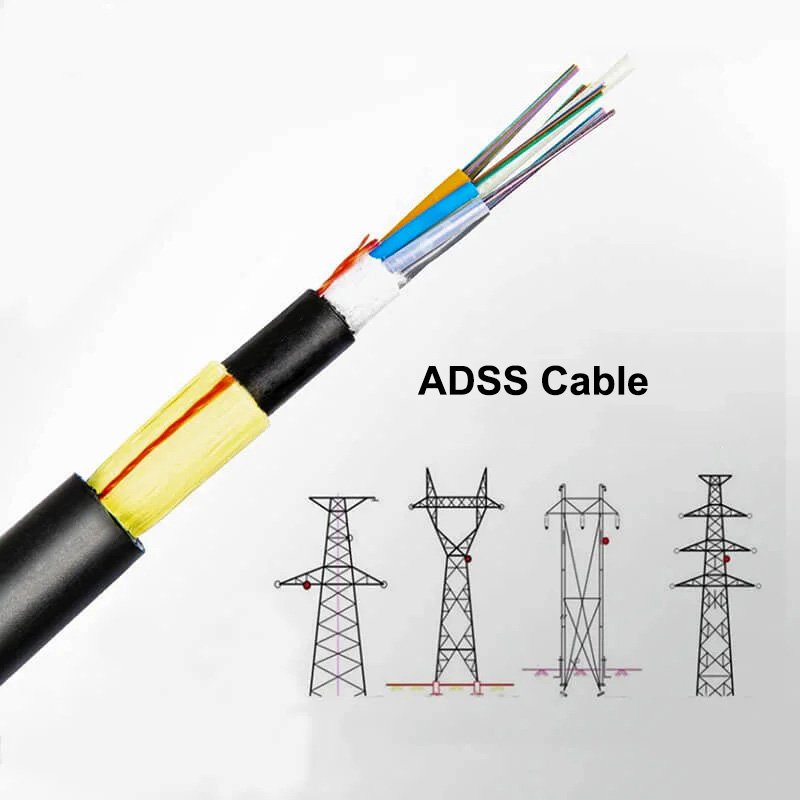

What is ADSS Fiber Optic Cable? Structure, Applications, and Installation Guide

In my years working at ABPTEL, I have often seen how important it is to choose the right type of fiber optic cable for each project. Among all the choices, ADSS (All-Dielectric Self-Supporting) fiber optic cable stands out when it comes to aerial installations. In this article, I want to share a complete view of ADSS fiber optic cables based on my real-world experience.

What is ADSS Fiber Optic Cable?

ADSS fiber optic cable is a special type of aerial fiber cable. It does not need a messenger wire or any metallic support. "All-dielectric" means it has no metal parts. "Self-supporting" means it carries its own weight. Because of this, it can be used next to high-voltage power lines without danger.

From my projects in South America and Africa, I have seen ADSS cables perform well in very harsh conditions. They resist strong winds, heavy snow, and lightning strikes.

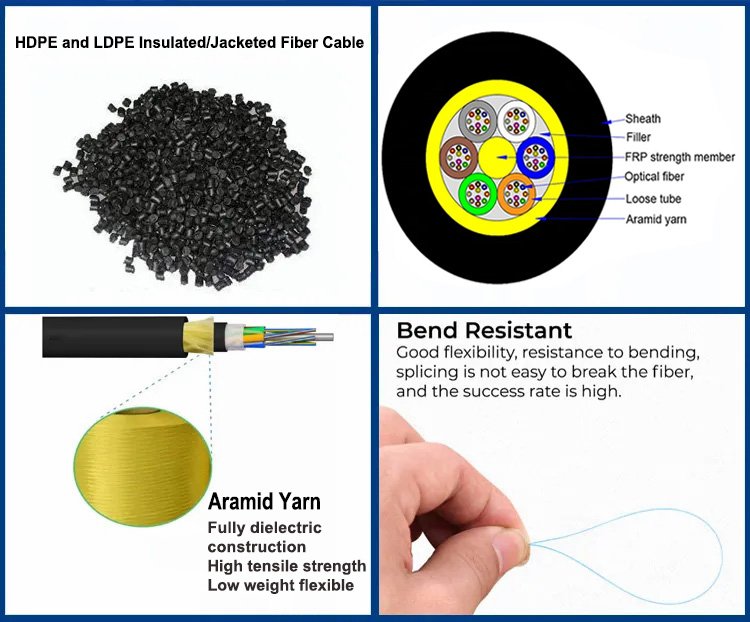

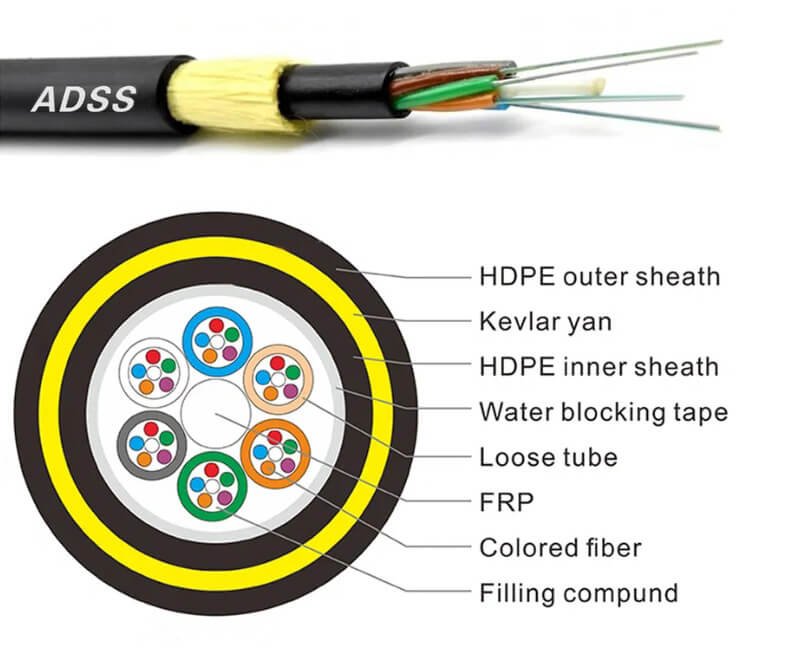

Structure and Design Features

When I first touched an ADSS cable at our ABPTEL lab, I was surprised by how light but strong it was. Here is what makes up a typical ADSS cable:

Central Strength Member

- Material: FRP (Fiber Reinforced Plastic) or Aramid Yarn

- Purpose: Provides tensile strength and prevents stretching

Loose Buffer Tubes

- Material: PBT (Polybutylene Terephthalate)

- Environment: Filled with gel or dry water-blocking materials

- Purpose: Protects optical fibers from moisture and mechanical damage

All-Dielectric Construction

- No metal parts

- High resistance to lightning and EMI (Electromagnetic Interference)

Protective Outer Jackets

| Jacket Type | Material | Usage |

|---|---|---|

| PE (Polyethylene) | Black PE | Low to Medium Voltage (below 100kV) |

| AT (Anti-Tracking) | UV-resistant, Tracking-Resistant PE | High Voltage (100kV–220kV and more) |

More Details on Jacket Choices

When selecting jackets, I usually check two things: voltage levels and environment. Here is a simple comparison:

| Factor | PE Jacket | AT Jacket |

|---|---|---|

| Voltage Endurance | <100kV | >100kV |

| UV Resistance | Medium | High |

| Anti-Tracking Property | No | Yes |

| Cost | Lower | Higher |

Common Applications of ADSS Fiber Optic Cable

Based on my hands-on experience in FTTA deployments and data center backbones, ADSS cables are widely used in these areas:

Telecommunications Networks

- Backbone fiber deployment

- Rural and long-distance optical networks

Electric Utility Networks

- Fiber optic communication integrated with transmission towers

- Smart grid infrastructure

Smart City Infrastructure

- IP camera backhaul

- Traffic signal and smart lighting networks

Highway and Railway Communications

- Highway monitoring systems

- Railway signaling and communication lines

Advantages of Using ADSS Cables

I always recommend ADSS cables to my clients when they want a reliable, low-maintenance solution. Here are some advantages:

- No Metallic Support Needed: Faster and cheaper installation

- Immunity to Electromagnetic Fields: Stable data transmission even near strong electric fields

- Lightweight and Tough: Reduces load on towers and poles

- Cost-Effective: Lower lifetime costs due to simple maintenance

Installation Considerations for ADSS Cables

Installing ADSS cables might look simple. However, several factors can affect the long-term success of a project. Here is what I always look at:

Span Length

| Span Category | Typical Span Length |

|---|---|

| Short Span | 50-200 meters |

| Medium Span | 200-800 meters |

| Long Span | 800-1500 meters |

Weather Factors

- Wind pressure

- Ice accumulation

- UV radiation

Pole and Tower Load Calculation

- Check pole strength to avoid bending or breaking

Jacket Type Based on Voltage Environment

- Use PE jacket under 100kV lines

- Use AT jacket above 100kV lines

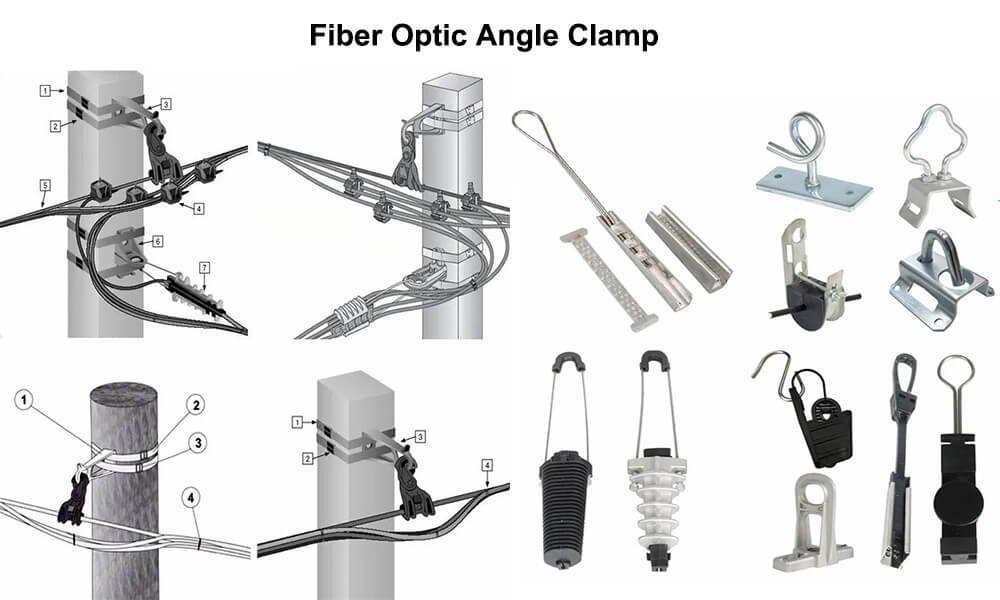

Common Installation Accessories

From my projects, the following accessories are a must for proper installation:

| Accessory | Purpose |

|---|---|

| Suspension Clamp | Reduces dynamic stress on the cable |

| Dead-End Clamp | Secures cable ends |

| Vibration Damper | Prevents Aeolian vibrations that cause fatigue |

Technical Specifications of ABPTEL ADSS-100M Cable

At ABPTEL, we design the ADSS-100M model for medium-span applications. Here is the basic spec sheet:

| Item | Specification |

|---|---|

| Fiber Type | Single Mode (ITU-T G.652D) |

| Fiber Count | 12 fibers |

| Cable Structure | 1 FRP Central Strength Member + 6 Loose Tubes |

| Central Strength Member | FRP, 2.0mm diameter |

| Loose Tube Material | PBT, 2.1mm diameter |

| Filler Rod | LDPE |

| Strength Member | Aramid Yarn |

| Outer Sheath Material | PE |

| Cable Diameter | 10.0mm ± 0.2mm |

| Cable Weight | 96kg/km ± 5kg |

| Span | 100 meters |

| Min. Bending Radius (No Tension) | 10 × Cable Diameter |

| Min. Bending Radius (Under Tension) | 20 × Cable Diameter |

| Installation Temperature Range | -20°C to +60°C |

| Operating Temperature Range | -40°C to +70°C |

| Standard Delivery Length | 1km per drum |

Optical Fiber Characteristics (G.652D)

| Parameter | Value |

|---|---|

| Attenuation @ 1310nm | ≤0.35 dB/km |

| Attenuation @ 1550nm | ≤0.22 dB/km |

| Zero Dispersion Wavelength | 1302-1322 nm |

| Mode Field Diameter | 9.2±0.4 μm |

| Bending Loss | ≤0.1dB |

Fiber Color Coding

- Blue

- Orange

- Green

- Brown

- Gray

- White

- Red

- Black

- Yellow

- Violet

- Pink

- Aqua

Packing and Marking

- Plywood drum packing

- Meter marking printed for easy installation

Conclusion: Build Reliable Aerial Networks with ABPTEL ADSS Solutions

Choosing the right ADSS cable is critical for aerial network success. Based on my field experience in working with electric utilities and telecom networks worldwide, I can confidently say that ADSS cables from ABPTEL deliver unmatched quality, reliability, and value.

If you have a project for data centers, FTTA, smart cities, or utility grids, reach out to me at ABPTEL. We will help you find the right solution tailored to your needs.

✉️ Email: anya@abptel.com

🌐 Website: www.abptel.com