Is It Time to Reassess Your ADSS Fiber Optic Cables Specifications?

Are you worried that your ADSS fiber optic cables1 might not be up to the job? Do you feel tension when projects run into bottlenecks or overhead lines face unpredictable stress? Let me show you a better way forward.

ADSS fiber optic cables require precise attention to specifications. I recommend looking at core count, diameter, tensile ratings, and environmental conditions. These parameters help ensure smooth data transmission and reliable performance.

I recall my first ADSS2 project. I was anxious about the demanding load parameters. Then I saw how correct specifications eased my concerns. Today, I want to share my experience so you can skip trial-and-error and get things right on your first try.

Could the Right ADSS Cable Choice Optimize Your Network Performance?

I often see project managers struggle to pick the right ADSS fiber optic cable. They worry about core count, diameter, and tension ratings. I understand their confusion, and I want to simplify the selection process for optimal network performance.

Choose an ADSS cable by analyzing your project’s environment, load conditions, and data capacity needs. Focus on cable diameter, fiber count (24-core, 96-core), and tensile rating. That way, you avoid overhead line disruptions and ensure stable data flow.

How Does Cable Selection Affect Network Outcomes?

I know many clients in the telecom sector who undervalue proper ADSS cable choice. This oversight leads to network inefficiencies and expensive rework. Let’s look deeper into some vital aspects:

Matching Core Count to Project Needs

Core count determines how many separate channels of fiber are inside one cable. Here’s a quick reference:

| Core Count | Typical Use Case | Examples |

|---|---|---|

| 24 Cores | Small to mid-scale lines or expansions | Campus connections |

| 48 Cores | Medium network expansions | Local telecom lines |

| 72 Cores | Large networks with moderate redundancy | ISP backbone links |

| 96 Cores | High-density networks or data centers | Inter-city ring lines |

I usually ask clients about their expansion plans. If they see a higher demand, I suggest a 96-core or bigger. If capacity is smaller, 24 cores can be enough.

Diameter Considerations for Installation

Diameter matters for mechanical stress, wind load, and ice load. A thicker cable might handle higher tension but could be heavier. If your region sees extreme weather, a slightly bigger diameter can offer better durability.

| Cable Diameter | Approx. Weight (kg/km) | Recommended Wind Load (max) | Installation Note |

|---|---|---|---|

| 9.0 mm | 60 – 80 | Light to moderate | Good for short spans |

| 11.0 mm | 80 – 100 | Moderate | Suits typical overhead lines |

| 13.0 mm | 100 – 120 | Heavy loads | Better for harsh weather areas |

Considering Environmental Factors

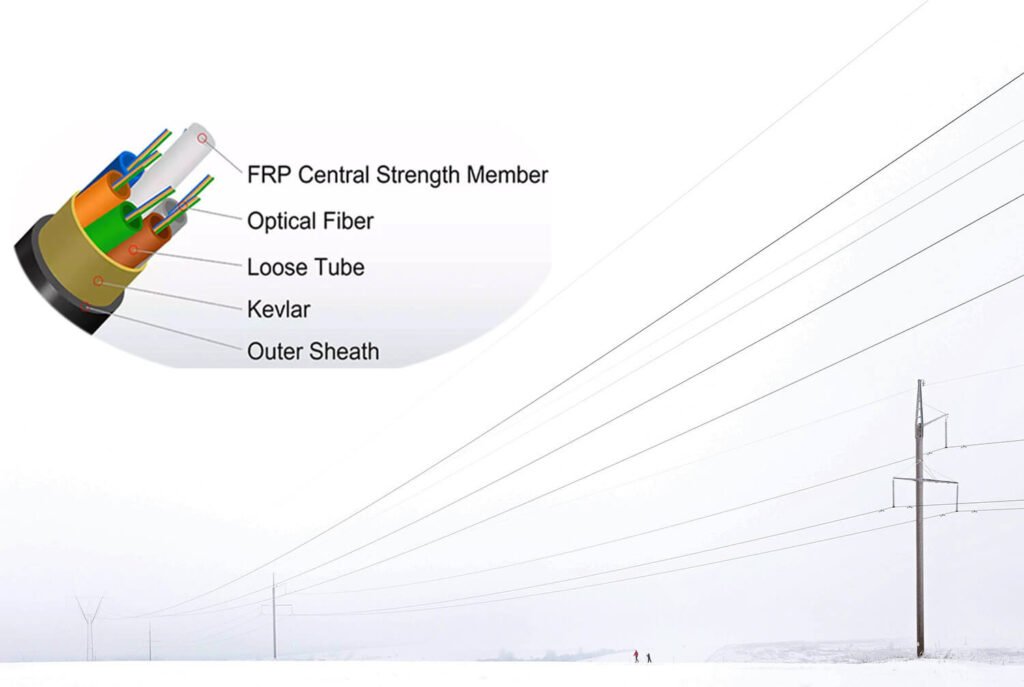

ADSS stands for All-Dielectric Self-Supporting. It doesn’t need a metallic messenger wire. This helps in high-voltage areas, as it reduces electrical interference. But you must confirm that the chosen cable sheath and jacket handle temperature extremes and UV exposure.

Selecting Proper Span Length and Tension

Span length affects the tension. Longer spans may require cables with higher tensile strength members. Meanwhile, for shorter spans in city environments, simpler tensile ratings might suffice. However, if you plan expansions, pick a cable that can handle a bit more tension than your immediate use case demands.

How Do We Test ADSS Fiber Optic Cable for Tensile Strength and Mechanical Reliability?

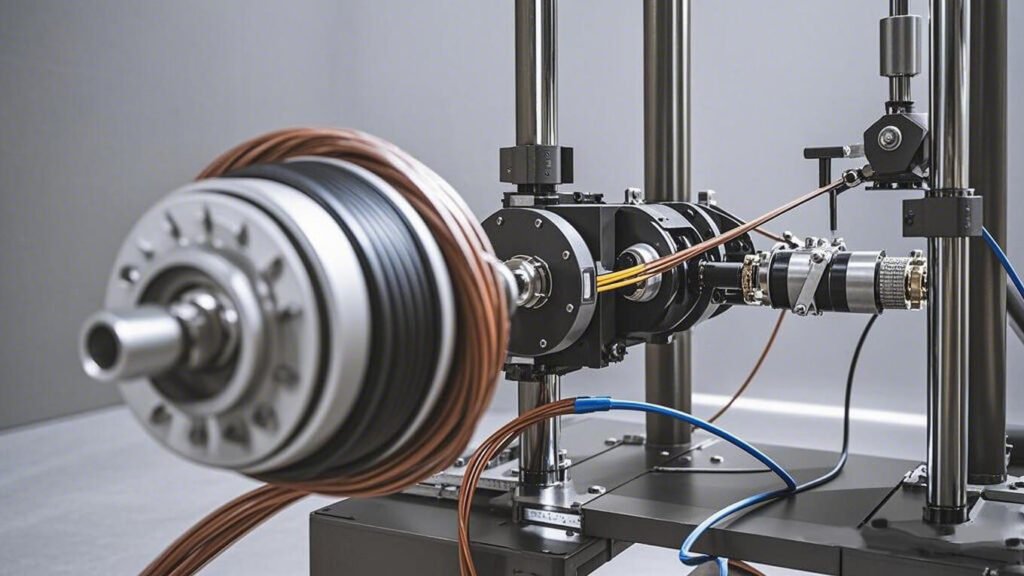

I conduct many tension tests in my role at Bright Power (China). Our ADSS cables need to handle wind, ice, and even accidental overloads. This is critical because an overlooked mechanical issue can lead to snapped cables or data loss.

Engineers must run standardized tensile tests to measure how a cable holds up under simulated loads. We usually gauge the break load, elongation, and post-stress fiber attenuation. These results confirm if the cable can handle real-world strains.

Evaluating Strength and Durability

When we talk about ADSS cable testing, we focus on tension, flex, and environmental simulation.

Tension Testing Essentials

Tension tests apply a pull force on the cable until we either reach the rated load or cause a break. Here is a simple outline of the process:

- Preparation: We cut a standard-length sample (around 1 to 2 meters).

- Mounting: We clamp both ends in a tensile machine.

- Loading: We apply tension at a predetermined rate until it reaches a set load or breaks.

- Measurement: We monitor elongation, break point, and fiber attenuation changes.

| Cable Model | Rated Tensile Strength (N) | Max. Elongation (%) | Fiber Attenuation Increase (dB) |

|---|---|---|---|

| ADSS-24C–Low T | 1500 – 2000 | <1.0 | <0.05 |

| ADSS-24C–MediumT | 2000 – 3000 | <1.0 | <0.05 |

| ADSS-24C–HighT | 3000 – 4000 | <1.0 | <0.05 |

| ADSS-96C–HighT | 3000 – 4500 | <1.0 | <0.05 |

Bending and Flex Tests

Flex tests simulate how cables behave when subjected to wind sway or tower vibrations. The process includes repeated bending cycles.

Temperature and Environmental Simulation

Real-world conditions can range from scorching sun to freezing winters. So, we put cables in climate chambers to replicate high and low temperatures. We also simulate humidity or water exposure to ensure there is no infiltration that might degrade the fiber.

Materials like PE (Polyethylene) or AT (Anti-Tracking)3 sheaths get validated to meet harsh environment needs.

What Are the Key Technical Specifications of ADSS Fiber Optic Cables?

I often get asked for a checklist of ADSS cable specifications. People want to know which parameters matter most. Let me outline the essentials: fiber count, diameter, strength member type, rated tensile, jacket material, and more.

ADSS cable specs include core count (24-core to 96-core), cable diameter, jacket material (PE or AT), tensile rating, and environmental endurance. Each parameter determines how well your network can handle external stresses. Matching them to your project requirements is critical.

Core Parameters That Influence Performance

Fiber-Specific Details

| Parameter | Description |

|---|---|

| Fiber Count | Number of fibers in a single cable (e.g., 24, 48, 72, 96). |

| Fiber Type | G652D, G657, etc. for single-mode. |

| Attenuation | Typically 0.34 dB/km @1310 nm or 0.20 dB/km @1550 nm. |

| Mode Field Dia | Usually 9.2 μm for single-mode. |

Mechanical Properties

| Parameter | Typical Range | Impact on Performance |

|---|---|---|

| Cable Diameter | ~9 mm to 15 mm | Affects weight, tension load, and span feasibility |

| Tensile Strength | 2 kN – 10 kN (depends on cable design) | Determines wind load capacity and overhead safety |

| Crush Resistance | ~1000 N/100 mm | Helps in cable tray or duct installations |

| Bend Radius | 10× cable diameter (dynamic) | Minimizes fiber damage during installation |

Environmental Durability

| Parameter | Typical Considerations |

|---|---|

| Sheath Material | PE or AT for high-voltage lines |

| Temperature Range | -40°C to +70°C |

| UV Resistance | Ensures longevity under direct sunlight |

| Water Penetration | Gel-filled or dry core to prevent water ingress |

Tailoring Specifications for Different Core Counts

A higher core count can alter cable diameter, weight, and tension loads. I see many enterprise clients shift from 24-core to 48-core after expansions. This reduces the need for multiple cables and helps streamline overhead line management.

Are You Ready for the Next Steps in ADSS Cable Procurement?

I remember my first major ADSS procurement project. I underestimated the documentation and compliance checks. I learned that good planning makes ordering much smoother.

Prior to placing an order, you should confirm fiber count, span length, tension requirements, and environmental conditions. After delivery, inspect outer sheath integrity, perform tension tests, and validate fiber attenuation. These checks ensure your cable meets specifications.

Planning and Post-Delivery Checks

Procurement shouldn’t be stressful. Here’s a step-by-step outline that often helps me guide clients.

Preparing Essential Details Before Ordering

- Project Layout: Identify overhead or underground segments, span lengths, and local weather conditions.

- Fiber Core Count: Decide on 24, 48, 72, or 96 cores based on data capacity requirements.

- Tensile Strength Requirement: Evaluate the maximum tension (wind + ice + safety factor).

- Sheath Selection: Choose standard PE or Anti-Tracking (AT) if near high-voltage lines.

- Certifications: Confirm compliance with IEC, ITU4, or other industry standards.

Checklist for Inspecting Received ADSS Cables

| Inspection Step | Method | Outcome |

|---|---|---|

| Visual Check | Inspect reel, jacket for damage | Identify shipping or handling issues |

| Length Measurement | Confirm the actual cable length | Ensure it matches your purchase order |

| Diameter & Weight | Use calipers and a scale | Verify compliance with specification |

| Tensile Test (Sample) | Test a short cable sample | Check rated tensile strength |

| OTDR Test | Check fiber continuity and attenuation | Ensure fiber performance meets expected dB/km |

I always encourage clients to test a small segment of each reel using an OTDR5. This avoids surprises later. If you notice any mismatch in attenuation or diameter, contact your supplier.

Documenting and Communicating Results

Keep test reports organized. If you find inconsistencies, share the data with your supplier. Reliable manufacturers respond with solutions or replacements.

OEM/ODM Options

If you have unique branding or functional requirements, an OEM/ODM approach6 might help. My factory in Shenzhen offers custom labeling, jacket colors, and special packaging.

Conclusion

Proper ADSS fiber optic cable selection and testing ensure reliable networks. I’ve seen projects thrive once the right specifications are in place. This guide helps you choose, test, and verify every detail so your ADSS deployment performs as intended.

-

This resource explains the basics of ADSS fiber optic cables, their design, and typical use cases. By clicking this link, you'll understand why ADSS is widely adopted for overhead installations. ↩

-

This resource helps you understand how ADSS cables function without a metallic messenger wire, making them ideal near high-voltage lines. Clicking this link clarifies the core advantages of ADSS design. ↩

-

This resource compares PE and AT jackets for different environments. Clicking the link helps you understand which sheath is best for high-voltage or harsh weather conditions. ↩

-

This resource outlines global standards like IEC and ITU that govern fiber cable specifications. Clicking this link helps you confirm your cables meet recognized industry benchmarks. ↩

-

This resource explains how OTDR tests measure fiber continuity and signal loss. By reading this, you’ll learn the significance of detecting attenuation issues early in fiber deployments. ↩

-

This resource clarifies custom manufacturing (OEM/ODM) for unique project specs or branding. Clicking this link shows how tailored solutions can meet special fiber or sheath requirements. ↩