How to Choose the Right ADSS Cable Accessories and Hardware?

Are you feeling uncertain about the stability of your ADSS fiber optic cable installation1? Do you worry about selecting improper clamps, tension hardware, or supports that might cause early cable failures? I understand your concerns, and I will show you how to eliminate doubts by diving deeper into the critical accessories and hardware needed for a robust, long-lasting ADSS cable setup.

ADSS cable hardware must support mechanical loads, protect fiber cores, and remain durable against environmental stresses. I suggest using properly rated clamps, brackets, and fittings. This ensures smooth installations and reduces downtime from structural or electrical hazards.

I still remember my first ADSS project. I used the wrong tension clamp2 because it looked cost-effective. That small oversight caused excessive cable sag and future line replacements. Through my own challenges, I learned that choosing the right accessories is as vital as selecting the right cable specifications. Let me share that experience with you so you can get it right the first time.

What Are the Main Types of ADSS Cable Installation Accessories?

I have worked with many different fittings and accessories. People often focus on the cable alone and neglect the hardware. That’s a risky approach. Hardware is what holds the cable in place and ensures mechanical stability. If these components fail, your entire system can suffer.

You should categorize ADSS accessories into clamps, tension assemblies, suspension assemblies, anchors, supports, and protection units. This breakdown helps you focus on each item’s purpose and alignment with your project requirements.

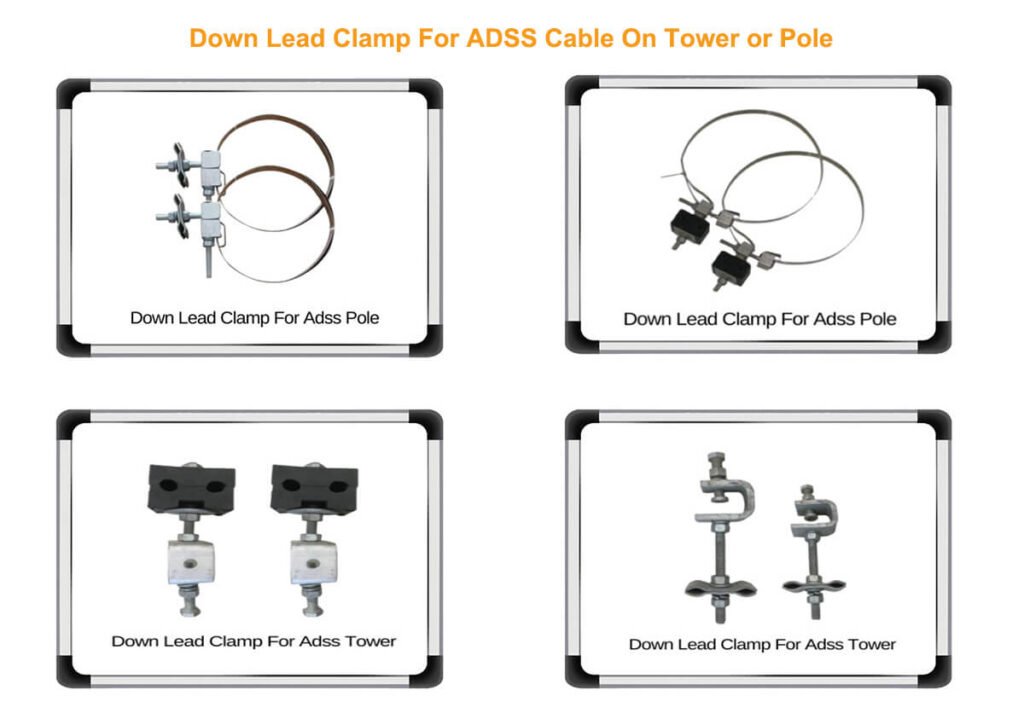

Clamps and Their Role

Clamps are essential for securing the cable along its route. Common clamp types include anchor clamps (for terminal points or heavy loads) and suspension clamps (for mid-span or intermediate support). Each clamp type has a different structural design.

- Suspension Clamps: Used to cradle the ADSS cable at points between poles or towers. These clamps reduce bending stress and let the cable move slightly to handle wind.

- Anchor (Tension) Clamps: Used where the ADSS cable terminates or changes direction. They grip the cable tightly to handle pulling forces from the cable’s weight and tension.

Selecting the right clamp involves evaluating the load rating, span length, and cable diameter.

Tension Assemblies

Tension assemblies usually consist of tension clamps, dead-end grips3, and support brackets. They maintain the correct cable tension across a span. An ADSS cable’s self-supporting nature depends on precise tension control, so these assemblies are key to preventing sag or slack.

Suspension Assemblies

Suspension assemblies include a suspension clamp plus accessories like armor rods or neoprene inserts. They hold the cable mid-span and allow slight movement while safeguarding the fibers from excessive bending or vibration.

Anchors and Supports

Anchors fix the line at specific points, like at a tower or a building entry. They must handle the combined tension of the cable, wind load4, ice load, and safety factors. Supports guide the cable along the route.

Protection Devices

Fiber cables need protection from arcing, friction, or abrasion. Protection devices can be rubber sleeves, armor rods, or specialized coverings. They prevent repeated rubbing or wind-induced movement that can degrade the cable.

Additional Hardware

Other hardware might include grounding components, spacers, and vibration dampers. Aeolian vibration5 can damage fibers over time if left unchecked. Grounding hardware can help safely discharge static buildup, especially near high-voltage lines.

Why Is Proper Hardware Selection Important for ADSS Fiber Optic Cables?

Clients often assume a robust cable can handle everything. But hardware is the interface between your cable and the environment. If your clamps or anchors fail, even the best cable will get damaged.

Quality hardware ensures mechanical stability, reduces stress on the fibers, and extends the system’s operational life. Load distribution must be correct, fittings should match your cable diameter, and the anchor points must endure local environmental forces.

Below is a reference table showing how cable diameter and tension strength correlate to hardware choice:

| Cable Diameter (mm) | Typical Tension Rating (N) | Suitable Clamp Rating (N) | Common Application |

|---|---|---|---|

| 9 – 10 | 1500 – 2000 | 2000 – 3000 | Short-span installations, moderate wind load |

| 11 – 12 | 2000 – 3000 | 3000 – 4000 | Medium spans, occasional heavy wind or ice |

| 13 – 14+ | 3000 – 4500+ | 4500 – 6000+ | Long spans, strong wind regions |

How Can You Choose the Best Clamp or Fitting for Your ADSS Cable?

First, know your cable diameter and rated tension. Then, account for environmental stresses (wind, ice, salt spray, or high-voltage lines). Finally, pick a reputable supplier who offers certified mechanical tests.

Selecting the right clamp or fitting depends on technical specs, load rating, and the supplier’s quality control. Don’t focus solely on price. A cheap clamp can become your biggest headache. Some polymer anti-tracking hardware6 may be necessary if you’re near high-voltage lines.

What Are the Steps to Install ADSS Cable Accessories Correctly?

Even premium hardware can fail if incorrectly installed.

Installation guidelines revolve around safety, proper tensioning, alignment, and verifying that each accessory fits the cable.

- Planning: Gather engineering drawings, load calculations, and hardware instructions. Inspect the site for hazards.

- Pre-Installation Check: Inspect each clamp or fitting for cracks or deformities.

- Tension Calculation: Use pullers or tensioning rigs to maintain the specified cable tension. Keep a record of tension for each span.

- Clamp Installation: Align and tighten to recommended torque. Over-tightening can crush the cable, under-tightening can lead to slippage.

- Anchor and Bracket Setup: Mount anchors on stable structures. Level the bracket, use corrosion-resistant bolts.

- Mid-Span Supports & Dampers: Position vibration dampers at recommended intervals to mitigate Aeolian vibration.

- Final Checks: Walk the line, confirm no pinched cable or misalignment. Make sure each clamp is secure.

Which Inspection and Maintenance Routines Keep ADSS Hardware Reliable?

Periodic inspections, tension measurements, and fastener checks extend hardware life and prevent unexpected failures.

- Visual Check: Spot rust, cracks, or missing parts.

- Tension & Sag Measurement: Compare actual sag to design values.

- Torque Check: Re-tighten bolts if needed to compensate for vibrations.

- Corrosion Control: Clean hardware, apply anti-rust coatings if needed.

A proactive approach keeps your system stable through storms, temperature swings, and other environmental stresses.

Conclusion

ADSS fiber optic cables are only as reliable as the hardware supporting them. By choosing the right accessories, verifying load ratings, and following proper installation and maintenance steps, you protect your investment and ensure uninterrupted network performance.

-

This resource explains why choosing the correct method and hardware for ADSS fiber optic cable installation is crucial. Clicking it helps you understand best practices for stable deployments. ↩

-

This resource defines how tension clamps work and why they are essential. Clicking it helps you pick clamps that securely hold cables under mechanical loads. ↩

-

This resource covers how dead-end grips secure and terminate ADSS cables. Clicking it helps you maintain proper tension and cable stability at terminal points. ↩

-

This resource provides formulas and guidelines for wind load calculations. Clicking it helps you accurately size clamps and anchors for windy or storm-prone regions. ↩

-

This resource explains Aeolian vibration caused by wind. Clicking it helps you learn how vibration dampers protect cables from micro-bends or fiber damage. ↩

-

This resource shows how specialized hardware mitigates arcing near high-voltage lines. Clicking it helps you ensure your ADSS cables are protected in electrically charged environments. ↩