How Do Load-Bearing and Tensile Performance Affect ADSS Fiber Optic Cables?

In the intricate world of telecommunications, the structural integrity of ADSS fiber optic cables1 is crucial. Without proper load-bearing and tensile performance2, these cables can fail, leading to costly disruptions and unreliable communication networks.

Understanding the load-bearing and tensile performance of ADSS fiber optic cables is essential to ensure their reliability and longevity in various installation environments.

When I began my journey with Abptel3, the importance of these performance metrics became evident. Let's delve into how load-bearing and tensile performance play pivotal roles in the deployment and maintenance of ADSS fiber optic cables.

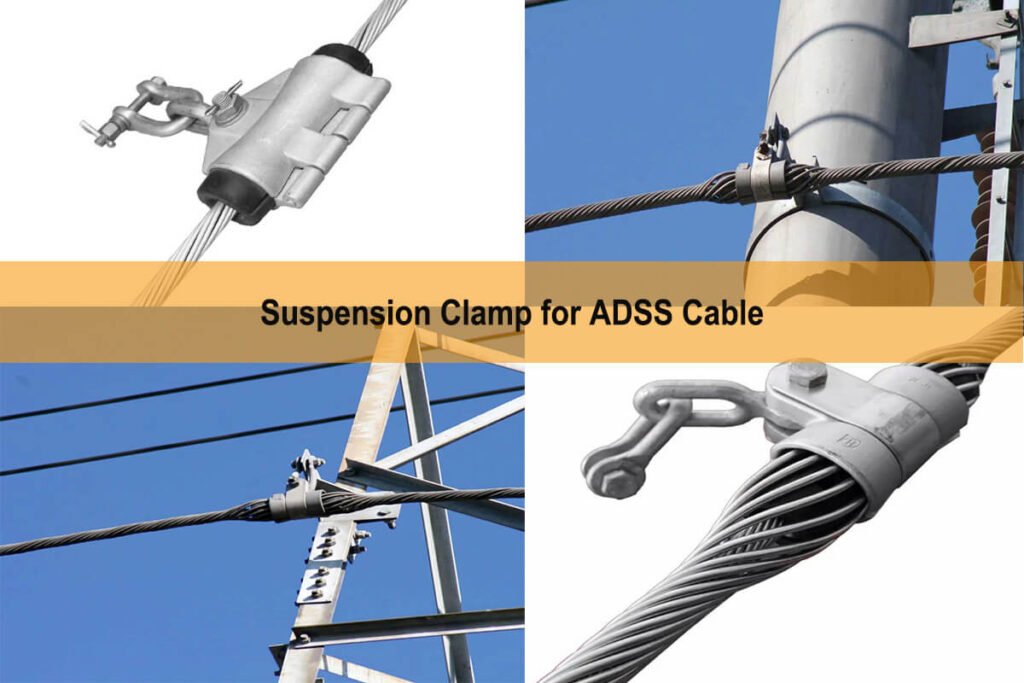

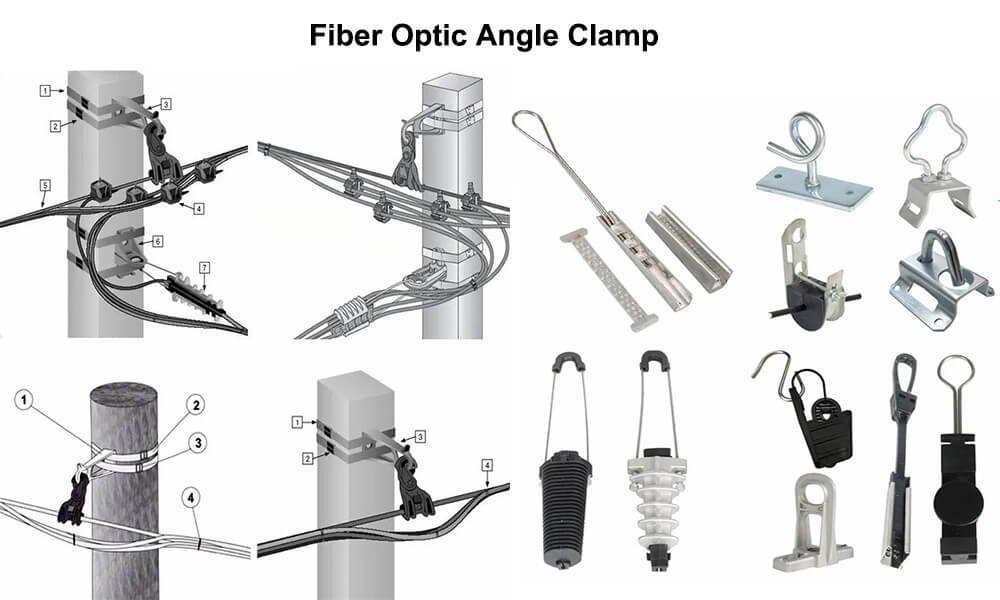

How Do Load-Bearing Capabilities Ensure the Stability of ADSS Fiber Optic Cables?

Ensuring that ADSS fiber optic cables have adequate load-bearing capabilities4 is fundamental to their stability and performance in various installation scenarios.

Load-bearing capabilities of ADSS fiber optic cables ensure that they can support their own weight and withstand environmental stresses without requiring additional support structures.

During a recent project at Abptel, we relied heavily on the load-bearing properties of our ADSS cables to install them alongside high-voltage power lines, eliminating the need for extra support and reducing installation time and costs.

Key Factors Influencing Load-Bearing Capabilities

Structural Design

The design of ADSS cables is meticulously crafted to balance strength and flexibility. By using all-dielectric materials5, these cables can support themselves without metallic components, reducing weight while maintaining durability.

Material Selection

High-strength materials such as aramid fibers6 and glass-reinforced plastics7 are used to enhance the load-bearing capacity of ADSS cables. These materials provide the necessary tensile strength to support the cable under various environmental conditions.

Tension Management

Proper tension management during installation ensures that the cables are neither too loose nor overly strained. This balance is critical to maintaining the cable's structural integrity and performance over time.

Load-Bearing Mechanisms

| Mechanism | Description |

|---|---|

| Self-Supporting Structure | ADSS cables are designed to support their own weight, allowing for easy installation without additional hardware. |

| Environmental Resilience | The cables can withstand wind, ice, and thermal expansion, maintaining stability in harsh conditions. |

| Flexibility | Despite their strength, ADSS cables remain flexible, allowing them to adapt to dynamic environmental changes without compromising their load-bearing capacity. |

Benefits of Robust Load-Bearing Capabilities

- Reduced Installation Costs: Eliminates the need for additional support structures, lowering overall project expenses.

- Enhanced Durability: Ensures long-term performance and reduces maintenance requirements.

- Increased Flexibility: Facilitates easier installation in diverse environments, including urban and rural settings.

- Improved Reliability: Minimizes the risk of cable sagging or failure, ensuring consistent communication performance.

Case Study: Load-Bearing Success at Abptel

In a challenging installation near a coastal region, our ADSS cables demonstrated exceptional load-bearing performance despite high winds and heavy rainfall. The cables maintained their position and functionality, ensuring uninterrupted service for our client.

What Are the Best Practices for Conducting Tension Tests on ADSS Cables?

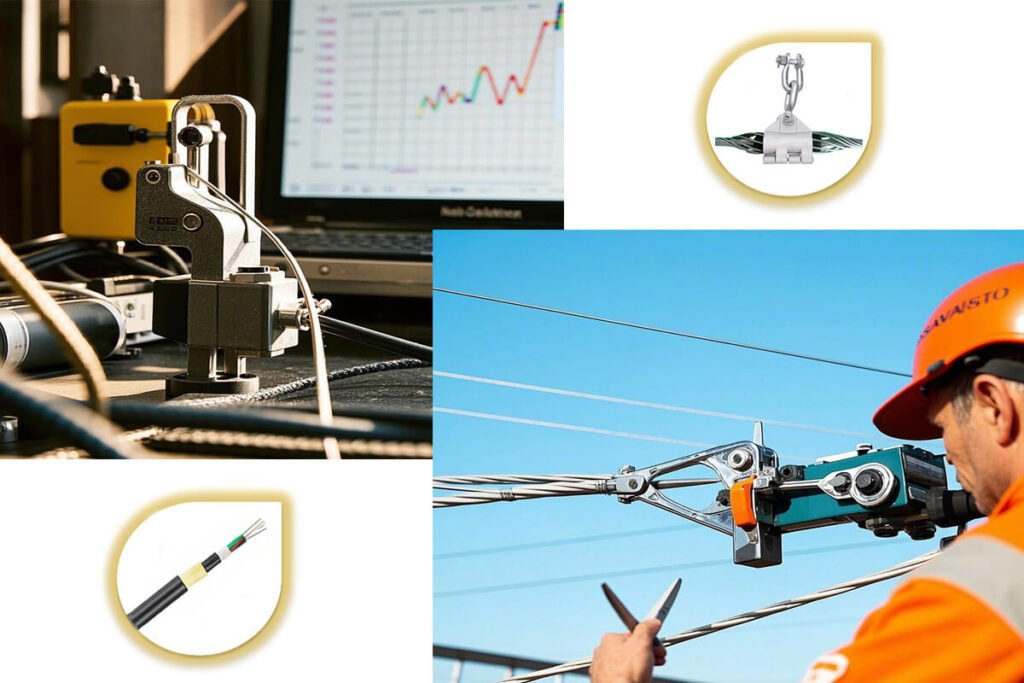

Conducting tension tests8 on ADSS fiber optic cables is crucial to verify their tensile strength and ensure they can withstand the mechanical stresses encountered during installation and operation.

Proper tension testing of ADSS cables is vital to validate their mechanical integrity and prevent potential failures in the field.

At Abptel, we've developed a comprehensive approach to tension testing that guarantees our ADSS cables meet the highest industry standards and perform reliably in real-world applications.

Essential Steps for Tension Testing

- Sample Selection: Choose representative samples from different production batches to ensure consistent quality.

- Equipment Calibration: Use calibrated tension testing machines to obtain accurate and repeatable results.

- Controlled Environment: Conduct tests in a controlled environment to minimize external variables that could affect the outcomes.

- Gradual Load Application: Apply tension gradually to accurately determine the cable's response to increasing stress.

- Data Recording: Record all relevant data, including maximum tensile strength, elongation, and failure points.

Tension Testing Protocol

| Step | Description |

|---|---|

| Preparation | Select and prepare cable samples, ensuring they are free from defects and properly labeled. |

| Setup | Install the cable sample in the tension testing machine, securing both ends firmly. |

| Load Application | Apply tension incrementally, monitoring the cable's response at each stage. |

| Measurement | Measure key parameters such as tensile strength, elongation, and strain. |

| Analysis | Analyze the data to assess whether the cable meets the required specifications and standards. |

Common Challenges and Solutions

| Challenge | Solution |

|---|---|

| Inconsistent Sample Quality | Implement strict quality control measures to ensure uniformity across samples. |

| Equipment Calibration Issues | Regularly calibrate testing equipment and perform routine maintenance. |

| Environmental Variations | Conduct tests in a controlled setting to reduce the impact of external factors. |

| Data Interpretation | Use standardized analysis methods and software to accurately interpret test results. |

Best Practices for Accurate Tension Testing

- Standardization: Adhere to industry standards such as IEEE9 and ISO10 to ensure consistency and reliability in testing procedures.

- Documentation: Maintain detailed records of all tests, including methodologies, conditions, and results, to facilitate traceability and quality assurance.

- Training: Ensure that personnel conducting the tests are thoroughly trained and understand the importance of each step in the process.

- Regular Audits: Perform regular audits of the testing process to identify and rectify any deviations or inefficiencies.

Importance of Accurate Tension Testing

Accurate tension testing not only validates the mechanical properties of ADSS cables but also helps in identifying potential weaknesses before they become critical issues in the field. This proactive approach enhances the overall reliability and lifespan of the cables, providing peace of mind to clients and stakeholders.

How to Assess the Tensile Strength and Load Capacity of ADSS Cables?

Assessing the tensile strength11 and load capacity12 of ADSS fiber optic cables is essential to ensure they can perform reliably under various operational stresses. This evaluation involves a combination of testing methodologies and analytical assessments to determine the cable's performance characteristics.

Evaluating the tensile strength and load capacity of ADSS cables is critical to guarantee their performance and prevent failures in demanding environments.

At ABPTEL, our rigorous assessment protocols ensure that our ADSS cables meet the highest standards of tensile strength and load capacity, providing our clients with dependable and resilient communication solutions.

Understanding Tensile Strength

Tensile strength refers to the maximum amount of tensile (stretching) stress that a material can withstand before failure. For ADSS cables, high tensile strength ensures that the cables can endure the mechanical forces encountered during installation and operation without breaking or deforming.

Load Capacity Assessment

Load capacity refers to the maximum load that a cable can support without experiencing excessive strain or failure. Assessing load capacity involves understanding both the static and dynamic loads that the cable may encounter in its operational environment.

Assessment Methodologies

Tensile Testing

Tensile testing is performed using specialized equipment that applies a controlled load to the cable until it reaches its breaking point. This test provides critical data on the cable's ultimate tensile strength (UTS) and elongation at break.

Finite Element Analysis (FEA)

Finite Element Analysis (FEA)13 is a computational method used to predict how the cable will respond to various loads and stresses. This analysis helps in optimizing the cable design to enhance its load-bearing capabilities.

Environmental Stress Testing

Cables are subjected to simulated environmental conditions such as temperature fluctuations, UV exposure, and moisture to evaluate their performance under real-world conditions.

Key Parameters to Measure

| Parameter | Description |

|---|---|

| Ultimate Tensile Strength (UTS) | The maximum stress the cable can withstand before failure. |

| Elongation at Break | The amount the cable can stretch before breaking, indicating its flexibility and ductility. |

| Yield Strength | The stress at which a material begins to deform plastically. |

| Modulus of Elasticity | A measure of the cable's stiffness, indicating how much it will deform under a given load. |

| Fatigue Resistance | The ability of the cable to withstand repeated loading cycles without failure. |

Interpreting Test Results

Interpreting the results of tensile and load capacity tests involves comparing the measured parameters against industry standards and the specific requirements of the installation environment. This comparison helps in determining whether the cable is suitable for the intended application.

Ensuring Compliance with Standards

ADSS cables must comply with various international standards such as IEEE 1222-2011 and ISO 9001. Ensuring compliance involves adhering to prescribed testing methodologies and meeting the specified performance criteria.

| Standard | Description |

|---|---|

| IEEE 1222-2011 | Specifies the testing and performance requirements for ADSS cables used on electric utility power lines. |

| ISO 9001 | Quality management systems standard that ensures consistent quality in manufacturing processes. |

| CE Certification | Compliance with health, safety, and environmental protection standards in Europe. |

| UL Listing | Safety certification for products sold in the US and Canada. |

Enhancing Load Capacity

| Strategy | Description |

|---|---|

| Material Optimization | Selecting materials with higher tensile strength and better elasticity to improve load-bearing capacity. |

| Structural Reinforcement | Incorporating additional strengthening layers or fibers to enhance the cable's mechanical properties. |

| Design Innovation | Developing innovative cable designs that distribute loads more effectively and reduce stress concentrations. |

| Regular Maintenance | Conducting periodic inspections and maintenance to identify and address any potential issues before they escalate. |

Case Study: Tensile Strength Assessment at ABPTEL

In a recent deployment project, our ADSS cables were subjected to rigorous tensile and load capacity assessments. The results demonstrated exceptional performance, with the cables maintaining their integrity under extreme wind and ice loads. This success was attributed to our advanced material selection and meticulous testing protocols, ensuring that our cables meet the highest standards of performance and reliability.

Conclusion

Load-bearing and tensile performance are critical factors that determine the reliability and longevity of ADSS fiber optic cables. By adhering to stringent testing protocols and quality standards, manufacturers like Abptel ensure that their ADSS cables can withstand the mechanical stresses of installation and operation. This commitment to excellence not only enhances the performance of communication networks but also provides clients with dependable and resilient solutions for their telecommunications infrastructure needs.

-

Provides a comprehensive overview of ADSS fiber optic cables, helping readers understand their structure and applications. ↩

-

Explains the difference between load-bearing and tensile performance, offering readers a deeper insight into these key metrics. ↩

-

Links to Abptel's official website, allowing readers to learn more about the company. ↩

-

Defines load-bearing capabilities and their importance in maintaining cable stability. ↩

-

Defines all-dielectric materials and their benefits in cable design. ↩

-

Details the properties and uses of aramid fibers, illustrating their role in enhancing load-bearing capacity. ↩

-

Explains the advantages of glass-reinforced plastics in load-bearing applications. ↩

-

Describes tension tests and their importance in verifying cable performance. ↩

-

Links to IEEE standards relevant to fiber optics, ensuring readers can reference specific guidelines. ↩

-

Directs readers to ISO standards related to telecommunications. ↩

-

Defines tensile strength, aiding in understanding its importance in cable performance. ↩

-

Explains load capacity assessment and its role in evaluating cable performance under stress. ↩

-

Provides an introduction to Finite Element Analysis (FEA) and its application in cable performance assessment. ↩